Wetting smoke dust-proof desulfurizing method

A new type of wet flue gas desulfurization technology, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., to achieve good economic benefits, good desulfurization effect, and equipment simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

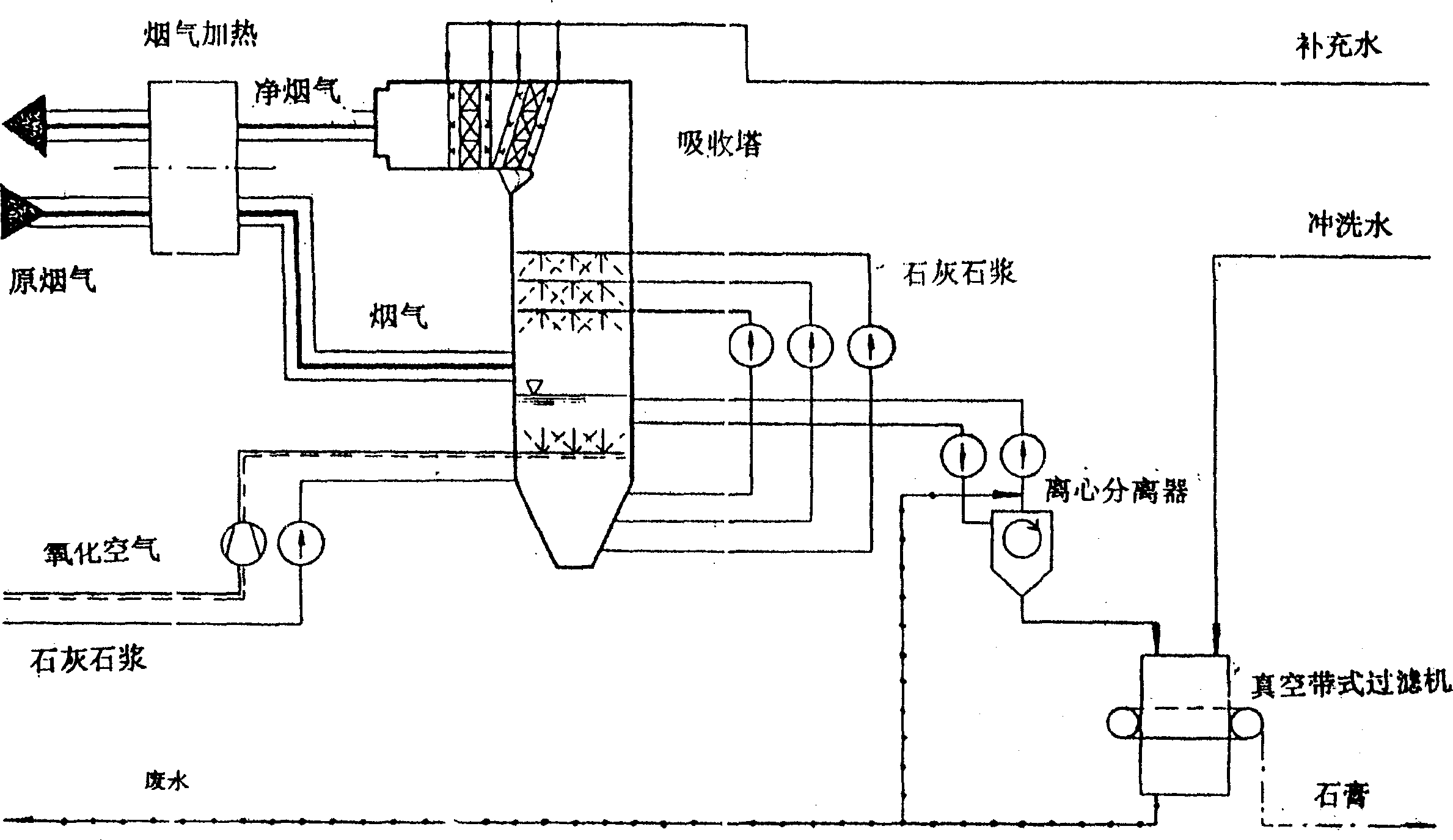

[0018] Such as figure 1 As shown, the new wet flue gas desulfurization and dust removal method of the present invention, it is to introduce the flue gas into the lower part of the absorption tower, make it cool by the evaporation of water, the lower absorption area is strongly mixed with the washing liquid in a countercurrent manner, and then the flue gas passes through the reaction Droplet separator at the top of the column, draining from the side.

[0019] The present invention includes absorption tower absorption zone, oxidation zone and neutralization zone.

[0020] The washing liquid of the present invention is pumped out from the stock tank and sent to the nozzles of each layer arranged up and down in the reaction tower, and is evenly distributed in the reaction tower in the form of very fine particles through the hole cone nozzles in each layer. SO in flue gas 2 Washed and neutralized, the calcium sulfite formed is oxidized to gypsum by injecting air into the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com