Pelletizing binder with desulfuration function and preparation method and application of pelletizing binder

A binder and pellet technology, which is applied in the field of pellet binder and its preparation, achieves the effects of reducing SO2 content, reasonable technology, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

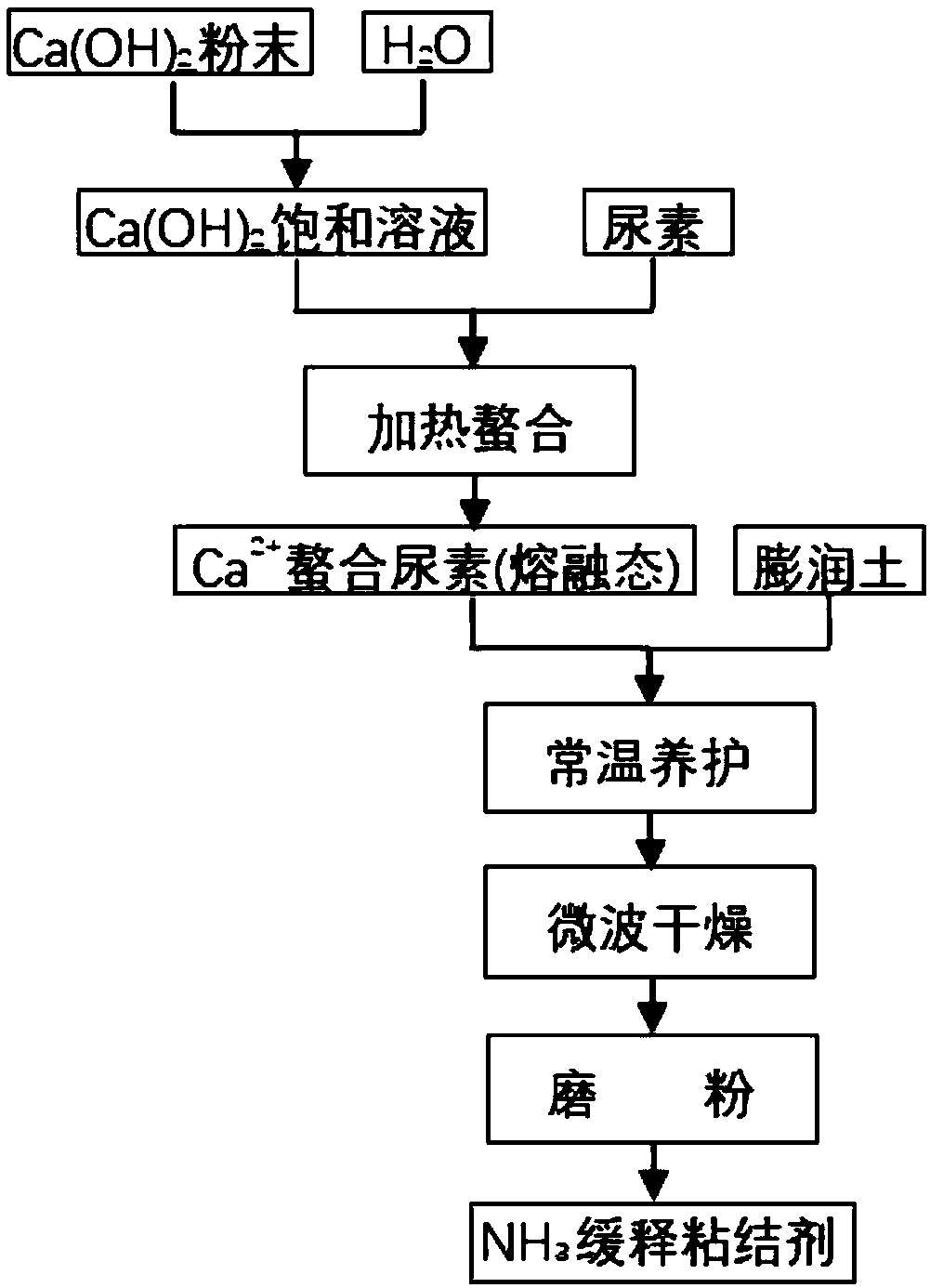

[0037] The pellet binder with desulfurization function of this embodiment includes the following components in terms of mass percentage: 2.5-10wt.% urea, 2.5-10wt.% Ca(OH) 2and 80-95wt.% bentonite, and the pellet binder is in the form of powder, and its particle size content of less than 0.074mm is greater than or equal to 95wt.%. Its preparation method comprises the following steps:

[0038] P1. Digest quicklime with water to form Ca(OH) 2 Saturated solution, add Ca(OH) 2 Equal quality of urea, fully stirred evenly;

[0039] P2. Heat and stir the mixed solution to evaporate the mixed solution until the reactants are in a molten state; specifically, stir and heat the mixed solution at a constant temperature of 100-120° C. for 0.5-3 hours;

[0040] P3. Add bentonite to the above melt and add water, and stir evenly; specifically, the quality of the added bentonite is Ca(OH) 2 and 4-19 times the mass sum of urea, and add 5-8wt.% water by mass percentage, and then stir evenly;...

Embodiment 2

[0053] The pellet binder with desulfurization function in this embodiment is basically the same as the above-mentioned embodiment, the difference is that the pellet binder in this embodiment includes the following components in terms of mass percentage: 5wt.% urea, 5wt. .% Ca(OH) 2 and 90wt.% bentonite, when prepared:

[0054] In step P1: 5 parts by mass of Ca(OH) 2 The saturated lime water that makes mixes with 5 mass parts urea;

[0055] In step P2: Stir and heat the mixed solution at a constant temperature for 1 hour at 120°C;

[0056] In step P3: add 90 parts by mass of bentonite, and add 8 parts by mass of water, and mix vigorously; the quality of bentonite is Ca(OH) 2 and 9 times the mass sum of urea;

[0057] In step P4: place the mixture at room temperature for 12 hours, then place it in a microwave oven with the temperature controlled at 100° C., heat for 1 hour, and then finely grind the agglomerated material to a particle size of less than 0.074 mm and a content...

Embodiment 3

[0060] The pellet binder with desulfurization function of this embodiment is basically the same as the above-mentioned embodiment, the difference is that the pellet binder in this embodiment comprises the following components in terms of mass percentage: 10wt.% urea, 10wt. .% Ca(OH) 2 and 80wt.% bentonite, when prepared:

[0061] In step P1: 10 parts by mass of Ca(OH) 2 The saturated lime water that makes mixes with 10 mass parts urea;

[0062] In step P2: stirring and heating the mixed solution at a constant temperature for 3 hours at 100°C;

[0063] In step P3: add 80 parts by mass of bentonite, and add 5 parts by mass of water, and mix vigorously; the quality of bentonite is Ca(OH) 2 and 4 times the mass sum of urea;

[0064] In step P4: place the mixture at room temperature for 14 hours, then place it in a microwave oven with the temperature controlled at 80° C., heat for 2 hours, and then finely grind the agglomerated material to a particle size of less than 0.074 mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com