Coke oven flue gas comprehensive purification system utilizing SDA semi-dry desulfurization

A semi-dry desulfurization and purification system technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of high one-time investment and operating costs, affecting catalyst stability, and high equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

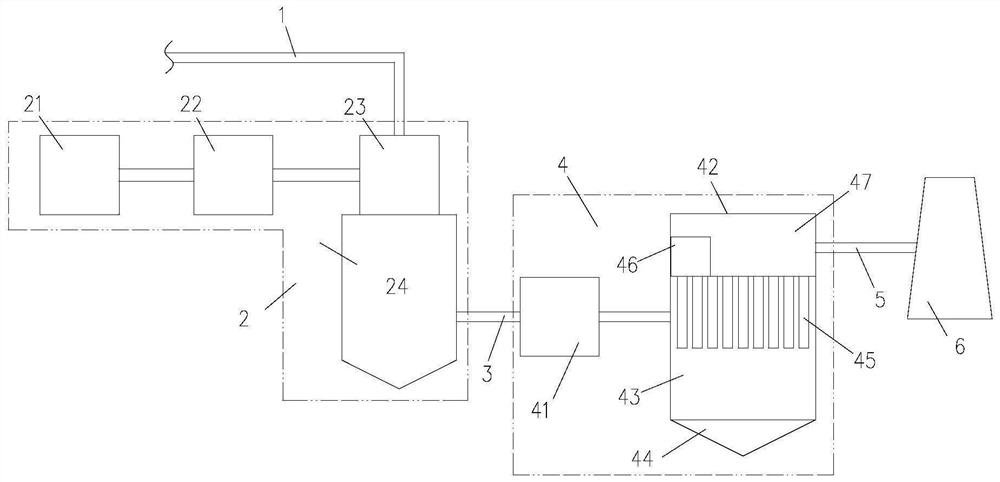

[0019] refer to figure 1 , a coke oven flue gas comprehensive purification system using SDA semi-dry desulfurization according to the present invention, comprising an original flue 1, an SDA semi-dry desulfurization module 2, a transition flue 3, ceramic Catalytic filter bag module 4, clean flue 5 and chimney 6, the SDA semi-dry desulfurization module 2 is arranged downstream of the original flue 1, and the SDA semi-dry desulfurization module 2 includes a slurry atomization system 23 and an SDA desulfurization tower 24. The outlet of the original flue 1 is connected to the slurry atomization system 23, the coke oven flue gas enters from the slurry atomization system 23 through the original flue 1, and fully mixes and reacts with the desulfurizer slurry sprayed out by the slurry atomization system 23 , the slurry atomization system 23 is arranged on the top of the SDA desulfurization tower 24, the SDA desulfurization tower 24 is connected to the ceramic catalytic filter bag mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com