Catalyst for preparing gasoline by coupling methanol with naphtha and preparation method thereof

A technology for the preparation of methanol and naphtha, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, and the preparation of liquid hydrocarbon mixtures. Effect of toluene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

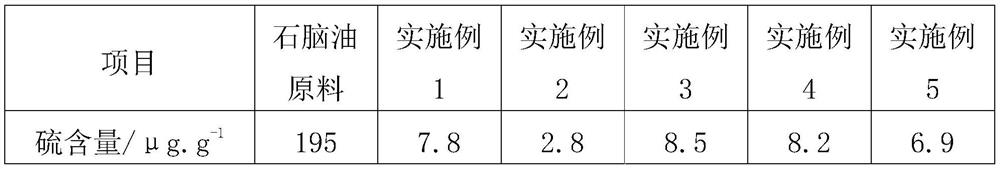

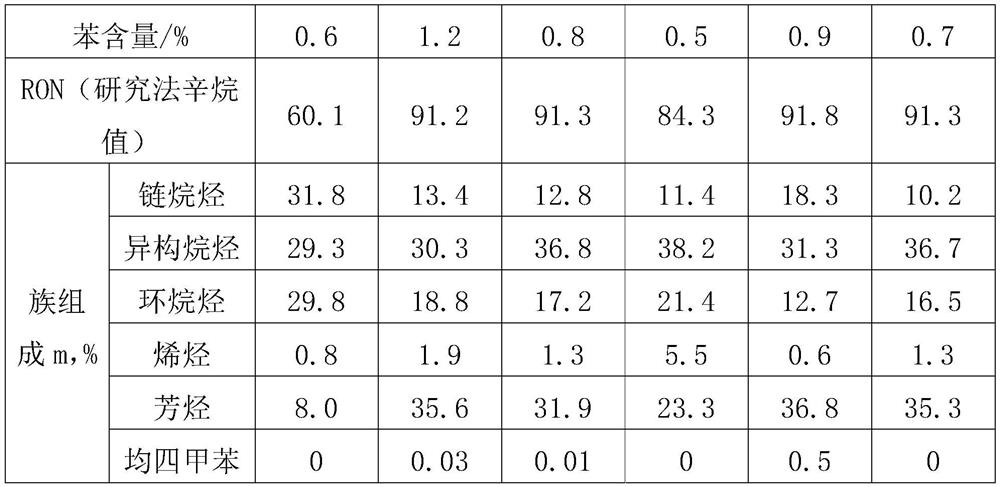

Examples

Embodiment 1

[0045] The catalyst composition of the present embodiment for the preparation of gasoline by coupling methanol with naphtha consists of: 82g component A, 83.5g component B and 60g component C, adding 25.98g of nitric acid acidified pseudo-boehmite as binding agent kneading to obtain the catalyst described in this example.

[0046] The component A is a small-grain HZSM-5 molecular sieve modified by metal zinc, and the SiO of the small-grain HZSM-5 molecular sieve 2 / Al 2 o 3 The molar ratio was 21.

[0047] The component B is a Hβ zeolite molecular sieve modified by metal nickel and lanthanum, and the SiO of the Hβ zeolite molecular sieve 2 / Al 2 o 3 The molar ratio was 30.

[0048] The component C is a metal composite oxide, which contains oxides of nickel, zinc, aluminum and titanium.

[0049] The preparation method of the catalyst that is used for naphtha coupling methanol to prepare gasoline of the present embodiment comprises the following steps:

[0050] (1) Weigh...

Embodiment 2

[0058] The catalyst composition that is used for the preparation of gasoline of naphtha coupling methanol in the present embodiment is: the component C of 79.3g component A, 85.4g component B and 60g, the pseudoboehmite that adds the nitric acid acidification of 25.98g as viscous The mixture is kneaded to obtain the catalyst described in this embodiment.

[0059] The component A is a small grain HZSM-5 molecular sieve modified by metal zinc and cerium, and the SiO of the small grain HZSM-5 molecular sieve 2 / Al 2 o 3 The molar ratio was 25.

[0060] The component B is Hβ zeolite molecular sieve and HZSM-35 molecular sieve modified by metal nickel and lanthanum, and the SiO of the Hβ zeolite molecular sieve 2 / Al 2 o 3 The molar ratio is 30, the SiO of the HZSM-35 molecular sieve 2 / Al 2 o 3 The molar ratio was 40.

[0061] The component C is a metal composite oxide, which contains oxides of nickel, zinc, aluminum, titanium, and cerium.

[0062] The preparation method...

Embodiment 3

[0071] The catalyst that is used for the preparation of gasoline by coupling methanol with naphtha in this embodiment consists of: 26.5g component A, 170.8g component B and 40g component C, add 25.98g of nitric acid acidified pseudo-boehmite as viscous The mixture is kneaded to obtain the catalyst described in this example.

[0072] The component A is a small grain HZSM-5 molecular sieve modified by metal zinc and cerium, and the SiO of the small grain HZSM-5 molecular sieve 2 / Al 2 o 3 The molar ratio was 25.

[0073] The component B is Hβ zeolite molecular sieve and HZSM-35 molecular sieve modified by metal nickel and lanthanum, and the SiO of the Hβ zeolite molecular sieve 2 / Al 2 o 3 The molar ratio is 30, the SiO of the HZSM-35 molecular sieve 2 / Al 2 o 3 The molar ratio was 40.

[0074] The component C is a metal composite oxide, which contains oxides of nickel, zinc, aluminum, titanium, and cerium.

[0075] The preparation method of the catalyst that is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com