Aluminum slag, desulfurizer and desulfurizing method for desulfurization of high silicon molten iron

A technology of hot metal desulfurization and high silicon, which is applied in the field of high silicon hot metal desulfurizer and aluminum slag for high silicon hot metal desulfurization, can solve the problems of poor desulfurization effect, and achieve the effects of promoting slag, increasing reaction heat, and economical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

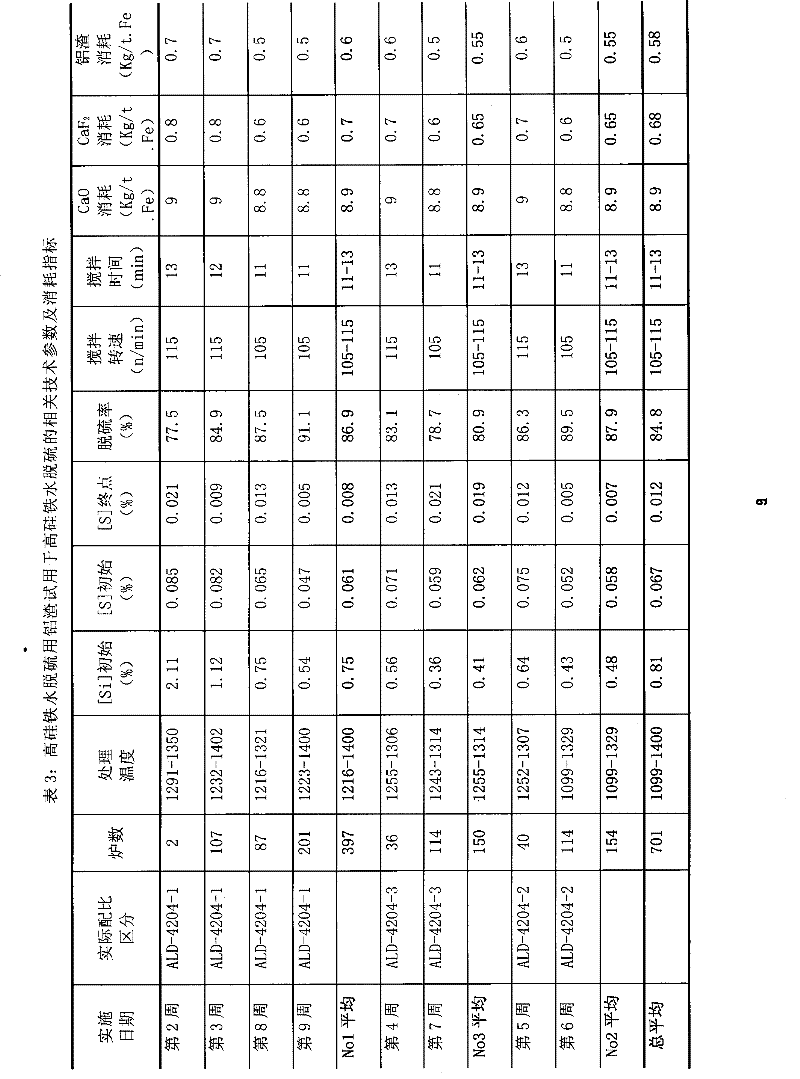

Examples

Embodiment Construction

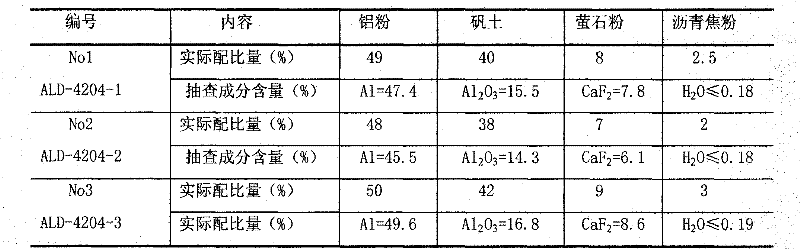

[0029] The aluminum slag used for desulfurization of high-silicon molten iron of the present invention is made up of the following raw materials in weight percentage:

[0030] Aluminum powder 48%~50%

[0031] Bauxite 38%~42%

[0032] Fluorite powder 7%~9%

[0033] Pitch coke powder 2% to 3%.

[0034] The preparation method of the aluminum slag for desulfurization of high-silicon hot metal includes uniformly mixing various raw materials to form a conventional mixed material. The particle size can be selected conventionally.

[0035] The aluminum slag used for desulfurization of high-silicon molten iron of the present invention has added bauxite and pitch coke powder, and increased the proportion of fluorite powder. The theoretical basis is as follows:

[0036] 1), the molten iron desulfurization reaction is carried out as follows:

[0037] [S]+(CaO)=(CaS)+[O] (1)

[0038] From the equilibrium constant expression of reaction (1), it can be seen that the desulfurization rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com