Combined two-stage flue gas desulfurization and dust-eliminating process

A technology for desulfurization, dust removal, and flue gas, which is applied in the direction of combined devices, use of liquid separation agents, and separation of dispersed particles. It can solve the problems of large wear of the nozzle pipeline system, inability to improve desulfurization efficiency, and increased maintenance workload. Small amount, convenient storage and comprehensive utilization, high dust removal efficiency and desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

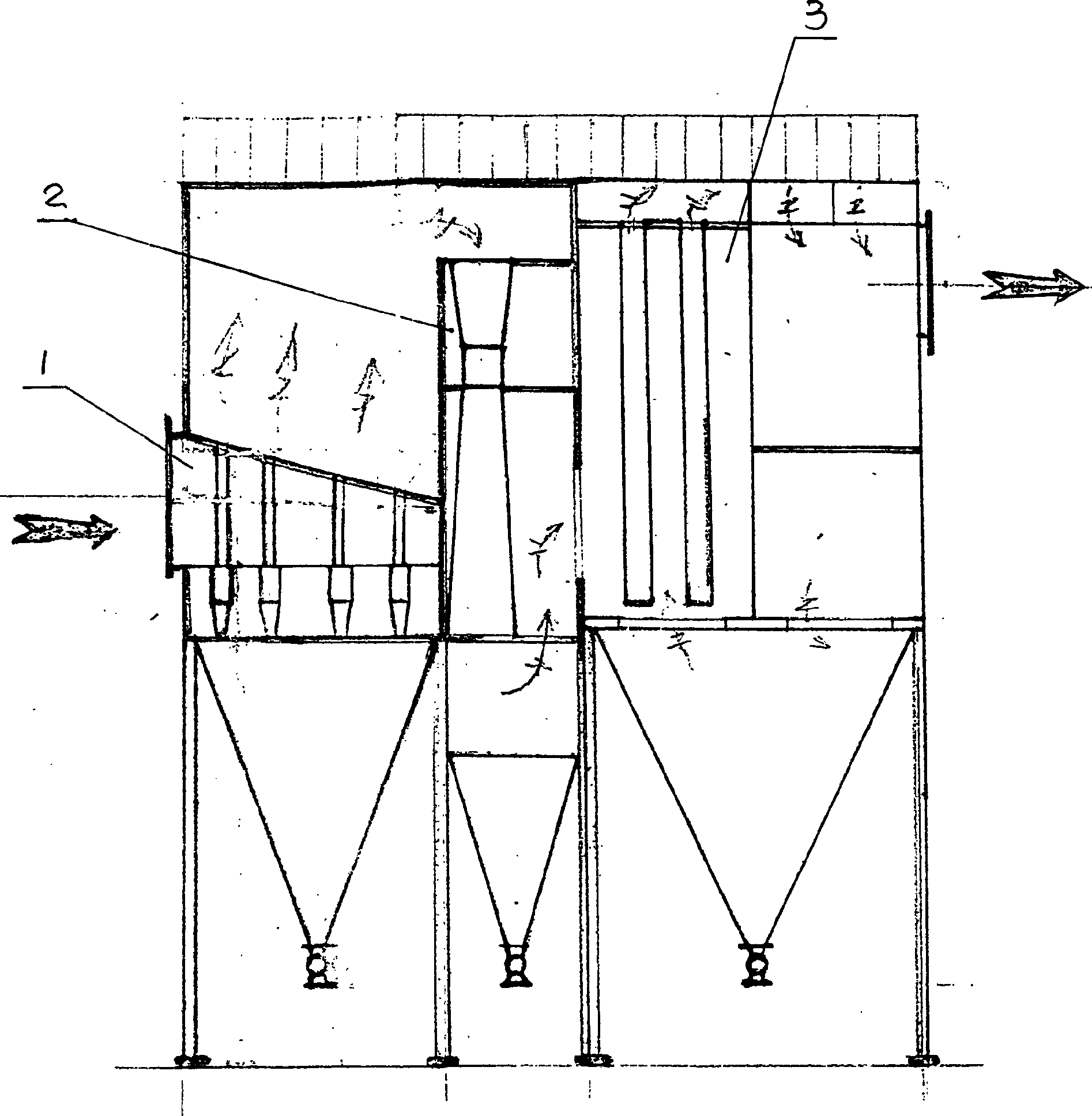

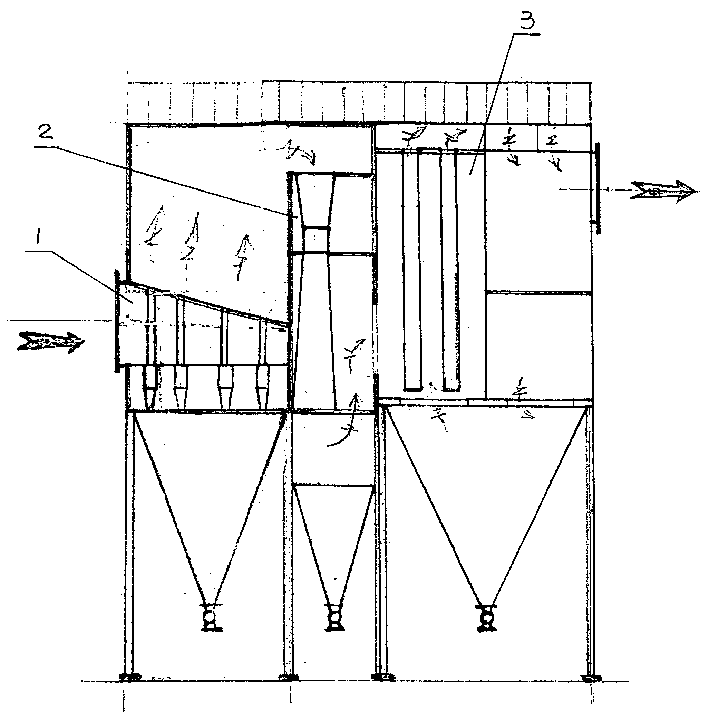

[0024] A composite two-stage flue gas desulfurization and dust removal process, which consists of ceramic multi-tube dust collector 1 (or electrostatic precipitator), active Venturi drying tower 2, and bag-type dust removal equipment 3. Three parts:

[0025] The front part is a ceramic multi-tube dust collector 1, which performs primary dust removal on the flue gas, and 90% of the flue dust is primary purified and enters the next process with a small dust concentration.

[0026] The front part can also be an electrostatic precipitator, which has the same function.

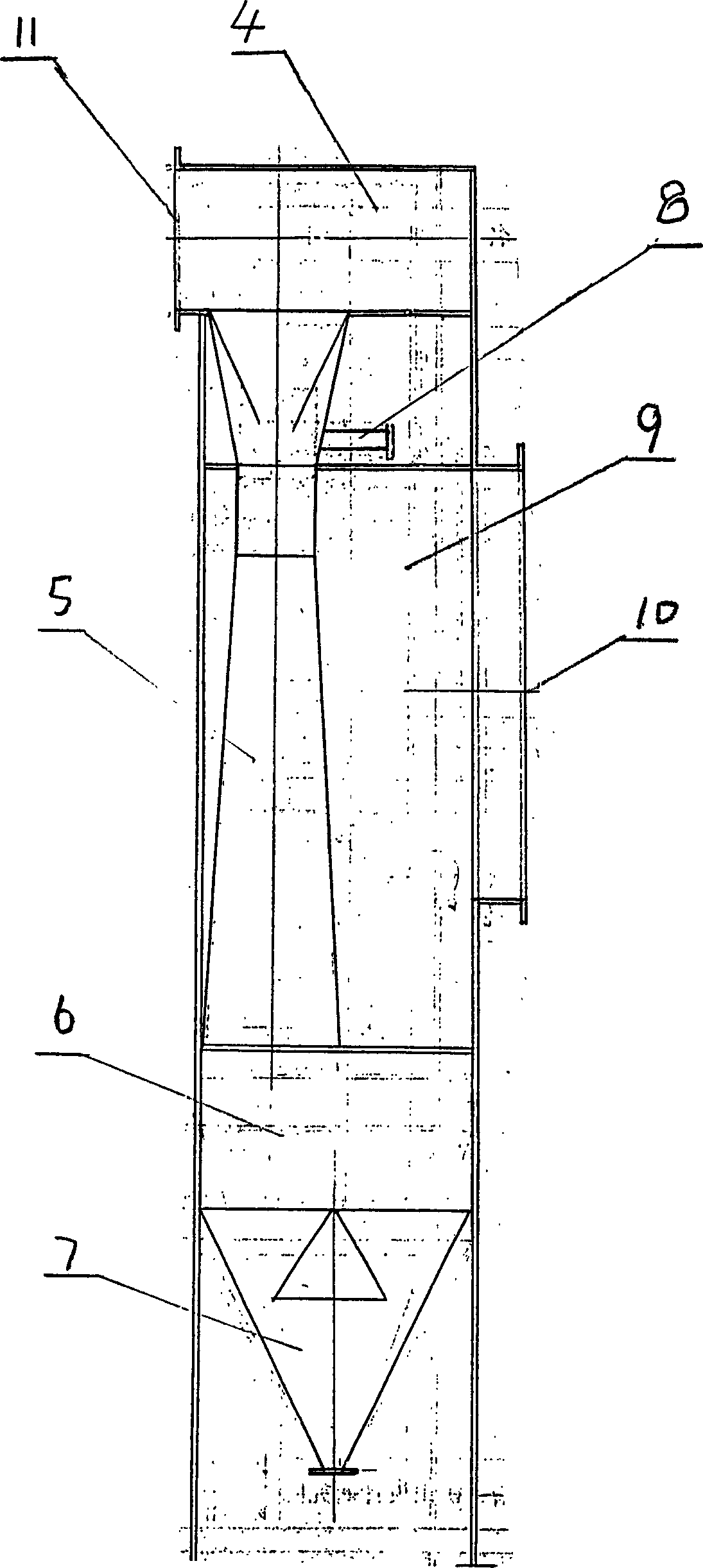

[0027]The first part is the active venturi drying absorption tower 2. The drying absorption tower includes upper inlet smoke box 4, multiple sets of Venturi tubes 5, multiple sets of desulfurization liquid inlet nozzles 8, middle smoke box 9, lower outlet smoke box 6, and ash collecting hopper 7 with impact-proof cones. Each set of Venturi tubes includes shrinkage tubes, throats, and diffuser tubes. The upper inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com