Method for wet desulphurization in CFB boiler

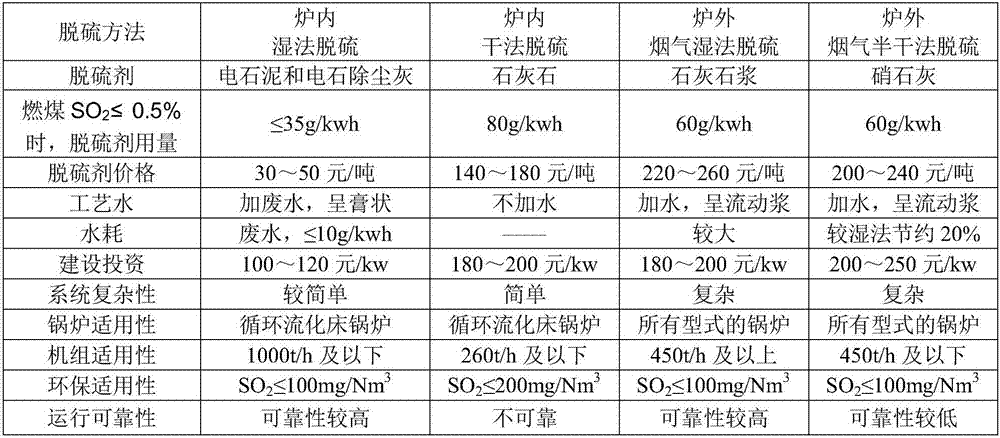

A technology of wet desulfurization and boiler furnace, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of equipment operation and maintenance personnel, high desulfurization operation cost, and poor operation reliability, etc., and achieve a good society and economic benefits, reducing secondary pollution, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

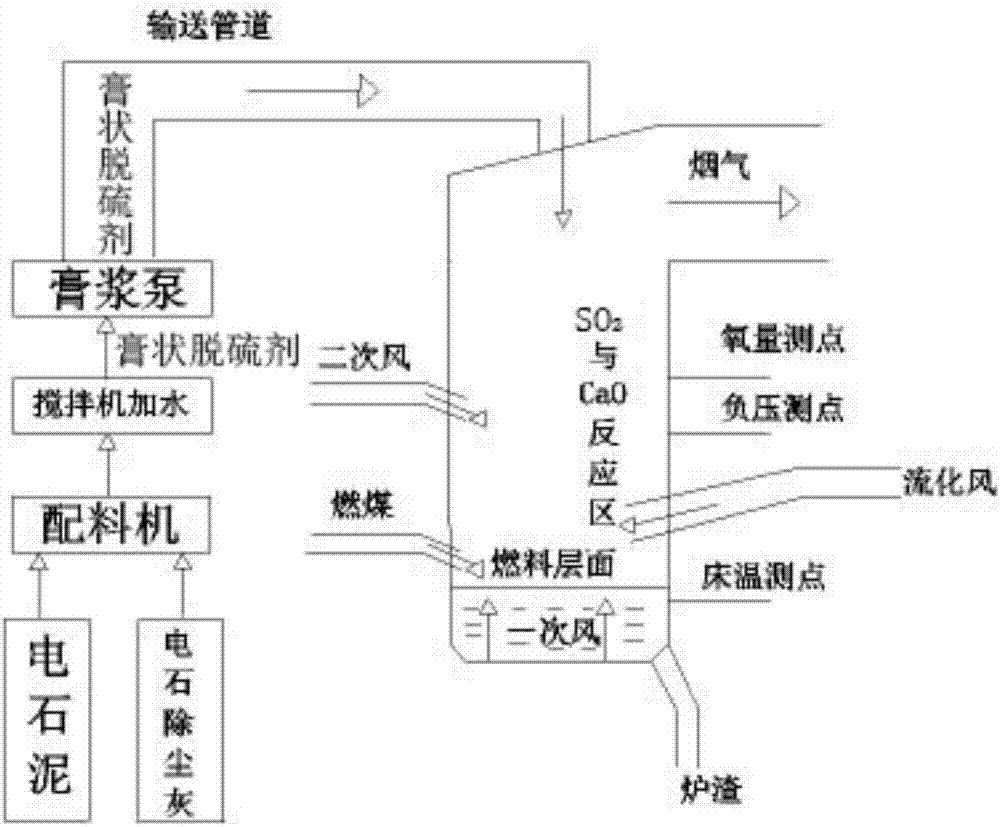

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, a method for wet desulfurization in a CFB boiler furnace

[0029] Take a company's 150MW generator set equipped with a 520t / h CFB boiler as an example. Boiler load 148-158MW, coal-fired calorific value 4800-5200kcal / kg, coal-fired sulfur content 0.3-0.45mg / kg, flue gas SO before desulfurization 2 Original emission value 900 / Nm 3 .

[0030] The wet desulfurization method includes the following steps:

[0031] 1. The desulfurizer uses 100% calcium carbide mud, and the calcium oxide content of the desulfurizer is 55-60%. Water (industrial wastewater) is added to the desulfurizer to prepare a paste-like desulfurizer, and the moisture content of the paste-like desulfurizer is 30-40%. .

[0032] 2. Set the calcium-sulfur ratio according to the calcium content of the desulfurizer and the sulfur content of the coal. Under the control of the DCS system, adjust the frequency of the reciprocating slurry delivery pump (20-30Hz), and the reciprocating slurry delive...

Embodiment 2

[0038] Embodiment 2, a CFB boiler furnace wet desulfurization method

[0039] Take a company's 150MW generator set equipped with a 520t / h CFB boiler as an example. Boiler load 148-158MW, coal-fired calorific value 4800-5200kcal / kg, coal-fired sulfur content 0.35-0.5mg / kg, flue gas SO before desulfurization 2 Original emission value 1000 / Nm 3 .

[0040] The wet desulfurization method includes the following steps:

[0041] 1. The desulfurizer is composed of 50% calcium carbide mud and 50% calcium carbide dust ash, and the calcium oxide content is 47-57%. Water is added to the desulfurizer to prepare a paste-like desulfurizer. The moisture content of the paste-like desulfurizer is 30-40% %.

[0042] 2. Set the calcium-sulfur ratio according to the calcium content of the desulfurizer and the sulfur content of the coal. Under the control of the DCS system, adjust the frequency of the reciprocating slurry delivery pump (20-30Hz), and the reciprocating slurry delivery pump will ...

Embodiment 3

[0048] Embodiment 3, a method for wet desulfurization in a CFB boiler furnace

[0049] Take a company's 150MW generator set equipped with a 520t / h CFB boiler as an example. Boiler load 148-158MW, coal-fired calorific value 4800-5200kcal / kg, coal-fired sulfur content 0.4-0.55mg / kg, flue gas SO before desulfurization 2 Original emission value 1200 / Nm 3 .

[0050] The wet desulfurization method includes the following steps:

[0051] 1. The desulfurizer is composed of 65% calcium carbide mud and 35% calcium carbide dust ash. The content of calcium oxide in the desulfurizer is 48-58%. Water is added to the desulfurizer to make a paste desulfurizer. The moisture content of the paste desulfurizer is 35-40%.

[0052] 2. Set the calcium-sulfur ratio according to the calcium content of the desulfurizer and the sulfur content of the coal. Under the control of the DCS system, adjust the frequency of the reciprocating slurry delivery pump (20-30Hz), and the reciprocating slurry deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com