Inflammable gas detecting instrument and desulphurization method thereof

A gas detector and circuit technology, which is applied in the field of combustible gas detectors and sulfur removal, can solve the problems of catalytic sensors such as large influence, poisoning, and reduced catalytic activity, and achieve reliable and accurate detection, accurate measurement results, and improved sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

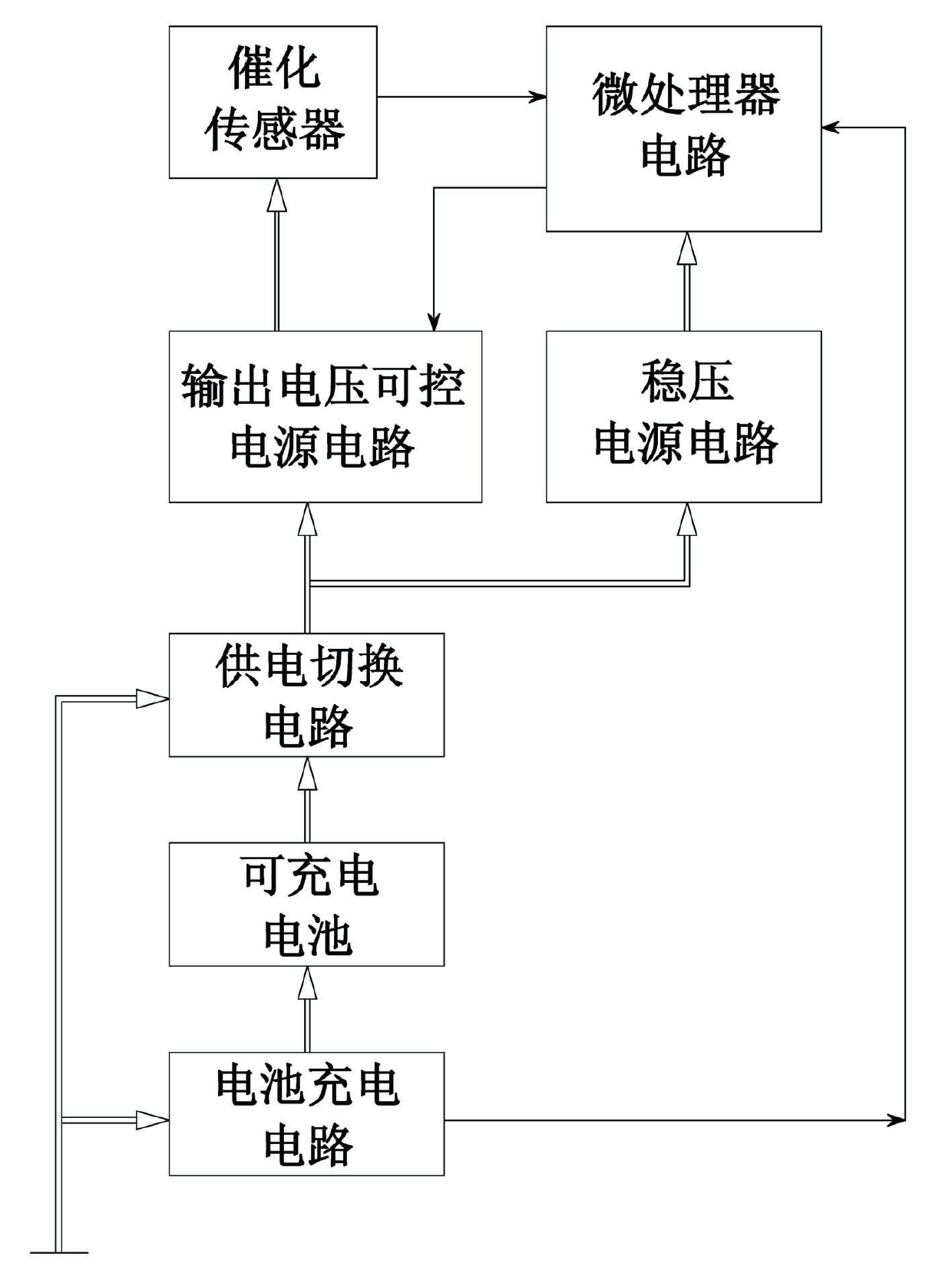

[0020] Such as figure 1 As shown, a combustible gas detector includes a microprocessor circuit, a catalytic sensor connected to the microprocessor circuit, an output voltage controllable power supply circuit, a regulated power supply circuit, a power supply switching circuit, a battery charging circuit and a Rechargeable Battery.

[0021] Wherein, the sensor voltage output end of the output voltage controllable power supply circuit is connected to the power supply end of the catalytic sensor to provide an operating voltage; the voltage control end of the microprocessor circuit is connected to the sensor voltage of the output voltage controllable power supply circuit Adjust the control terminal, so that according to the needs of sulfur removal, the microprocessor circuit controls the output voltage controllable power supply circuit, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com