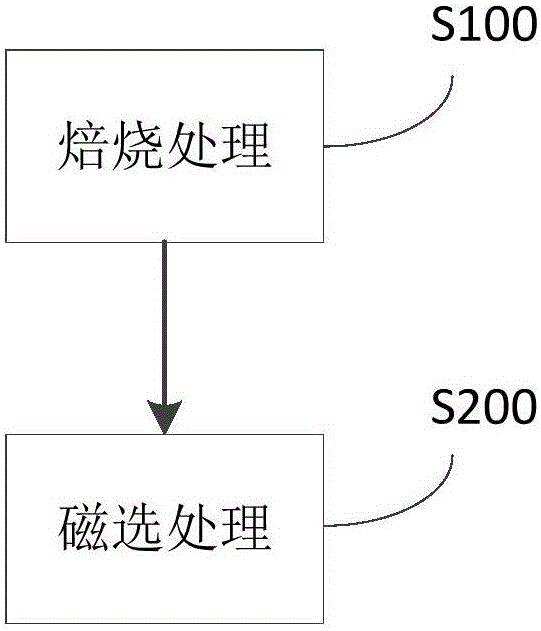

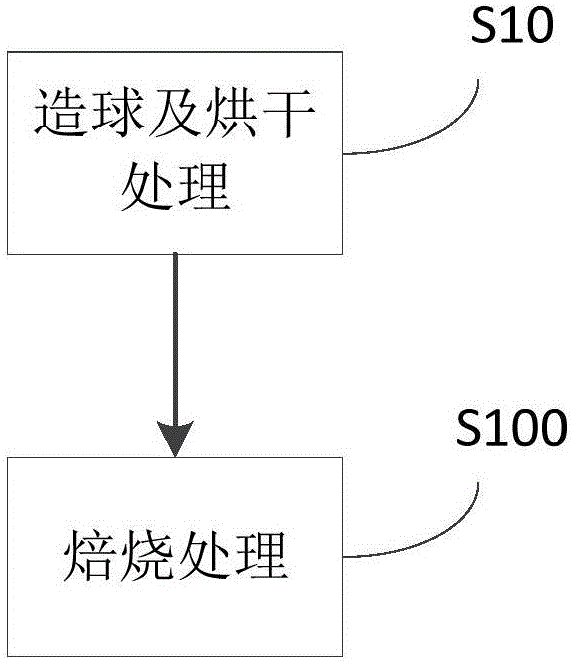

Method and system for treating sodium jarosite residue

A technology of yellow sodium iron vanadium and desulfurizer, which is applied in the chemical industry and can solve the problems of land occupation, environmental pollution, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Using jarosite slag with 28% iron grade, 2.5% nickel grade and 10.5% sulfur grade as raw material, the fixed carbon content of the reduced coal is 75%, marl is used as desulfurizer, and its calcium oxide content is 52%. The raw coal is blended in according to the C / O ratio of 1.0, and the marl is blended in according to the Ca / S ratio of 1.0. The above materials are mixed evenly, pressed into pellets, dried and put into the reduction furnace. The temperature in the furnace is 1180°C, and the reduction time is 26min. The reduced product can be magnetically separated to obtain ferronickel particles, wherein the grade of nickel reaches 19%, the recovery rate can reach 95%, and the desulfurization rate is 97%.

Embodiment 2

[0059] Use jarosite slag with 23% iron grade, 3.8% nickel grade and 11.8% sulfur grade as raw material, the fixed carbon content of the reduced coal is 82%, the desulfurizer is a mixture of calcium carbide slag and salt mud, and the reduced coal is based on C / The O ratio is 0.6, and the mixture of calcium carbide slag and salt mud is mixed according to the Ca / S ratio of 1.2. The above materials are mixed evenly, pressed into pellets, dried and put into the reduction furnace. The temperature in the furnace is 1350 ° C, and the reduction time is 20min. The reduced product can be magnetically separated to obtain ferronickel particles, wherein the nickel grade reaches 30%, the recovery rate can reach 98%, and the desulfurization rate can reach 97.8%.

Embodiment 3

[0061] Using jarosite slag with iron grade of 25%, nickel grade of 3.0%, and sulfur grade of 8.2% as raw material, the fixed carbon content of the reduced coal is 66%, calcium carbonate slag is used as the desulfurizer, and the reduced coal is formulated according to the C / O ratio of 0.8 Add marl according to the Ca / S ratio of 0.8, mix the above materials evenly, press them into pellets, dry them and put them in the reduction furnace. The temperature in the furnace is 1450°C, and the reduction time is 15 minutes. The reduced product can be subjected to dry magnetic separation to obtain ferronickel particles, in which the grade of nickel reaches 25%, the recovery rate can reach 97%, and the desulfurization rate can reach 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com