Device and method for high-sulfur bauxite suspension roasting oxidative desulfurization

A high-sulfur bauxite and suspension roasting technology, applied in the fields of metallurgy and mineral processing, can solve the problems of complex process, under-fired, long reaction time, etc., and achieve the effects of simple process flow, uniform temperature in the furnace, and stable product properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

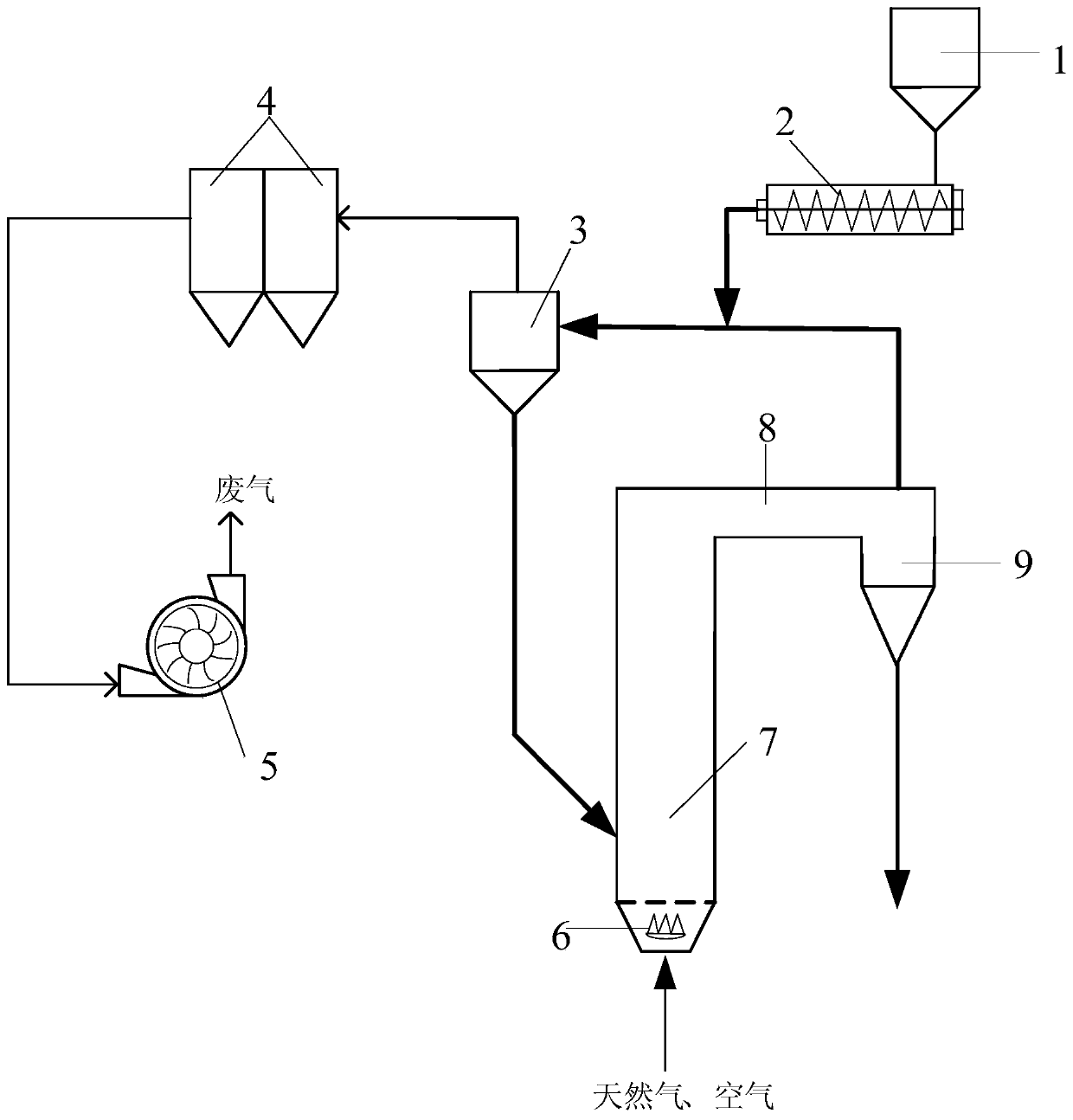

[0031] Suspension roasting oxidative desulfurization device for high-sulfur bauxite such as figure 1 As shown, it includes silo 1, screw feeder 2, primary cyclone separator 3, suspension roaster 7, secondary cyclone separator 9 and dust removal and desulfurization equipment 4; the outlet of silo 1 and the inlet of screw feeder 2 Connected, the outlet of the screw feeder 2 communicates with the feed port of the primary cyclone separator 3 through the feed port pipeline, and the discharge port of the primary cyclone separator 3 communicates with the feed port of the lower part of the suspension roaster 7, and the suspension The top of the roasting furnace 7 communicates with the feed port of the secondary cyclone separator 9 through the upper channel 8; wherein, the bottom of the suspension roasting furnace 7 is provided with a burner 6, and the gas outlet of the secondary cyclone separator 9 passes through the feed port pipeline It is connected with the feed port of the primary...

Embodiment 2

[0047] Device structure is the same as embodiment 1;

[0048] The high-sulfur bauxite used contains Al by mass percentage 2 o 3 64.61%, SiO 2 8.97%, S 4.77%, TFe9.46%, CaO 0.35%, MgO 0.41%, TiO 2 2.65%.

[0049] Method is with embodiment 1, and difference is:

[0050] (1) Particle size ≤ 0.074mm in the high-sulfur bauxite powder accounts for 90% of the total mass;

[0051] (2) The volume flow ratio of natural gas and air passed into the burner is 1:15, and O in the high-temperature oxidizing gas produced by combustion 2 The volume concentration of 20%;

[0052] (3) The ratio of the volume flow rate of the high temperature oxidizing gas in the suspension heating furnace to the mass flow rate of the primary solid material is 4.2m 3 / kg;

[0053] (4) The temperature of the oxidation roasting reaction in the suspension roaster is 900°C, and the residence time of the primary solid material in the suspension roaster is 40s;

[0054] (5) The mass percentage of S in the ba...

Embodiment 3

[0056] Device structure is the same as embodiment 1;

[0057] The high-sulfur bauxite used contains Al by mass percentage 2 o 3 59.77%, SiO 2 11.65%, S 2.97%, TFe7.33%, CaO 0.41%, MgO 0.88%, TiO 2 2.70%.

[0058] Method is with embodiment 1, and difference is:

[0059] (1) Particle size ≤ 0.074mm in the high-sulfur bauxite powder accounts for 75% of the total mass;

[0060] (2) The volume flow ratio of natural gas and air passed into the burner is 1:13, and O in the high-temperature oxidizing gas produced by combustion 2 The volume concentration of 19%;

[0061] (3) The ratio of the volume flow rate of the high temperature oxidizing gas in the suspension heating furnace to the mass flow rate of the primary solid material is 5.1m 3 / kg;

[0062] (4) The temperature of the oxidation roasting reaction in the suspension roaster is 1050°C, and the residence time of the primary solid material in the suspension roaster is 45s;

[0063] (5) The mass percentage of S in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com