Method for desulfurization of flue gas in boiler by using red mud

The technology of boiler flue gas and red mud slurry is applied in the field of boiler flue gas desulfurization, which can solve the problems of complicated preparation process, large flue gas resistance and high manufacturing cost, and achieve the effects of simple preparation, saving operation cost and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

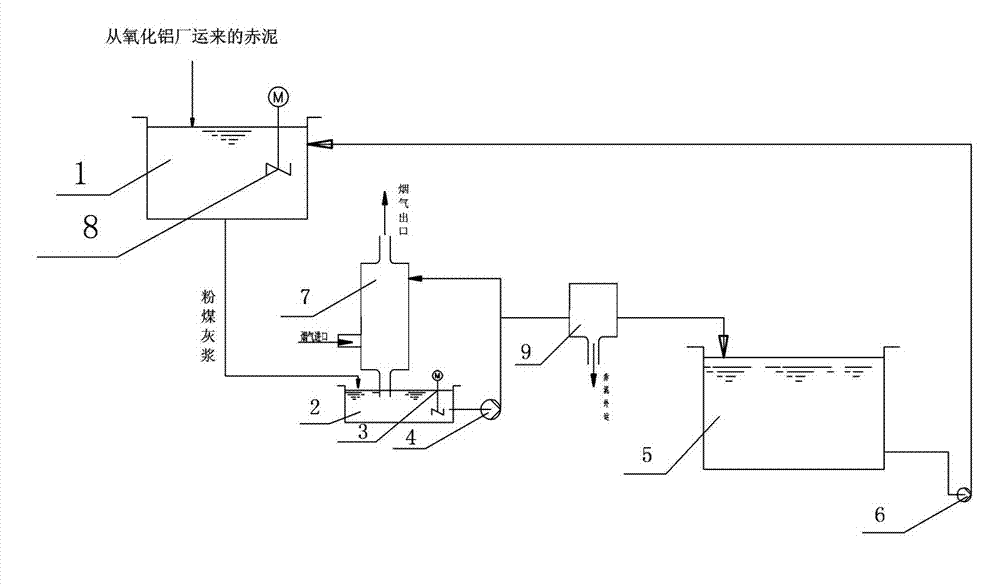

[0040] The present invention utilizes red mud slurry to carry out the method for boiler flue gas desulfurization, and the detailed steps of this method are as follows:

[0041] a. Preparation of red mud slurry:

[0042] The red mud slurry is industrial waste red mud produced in the alumina industry, the red mud is introduced into the red mud slurry preparation tank 1, water is added and stirred evenly by the agitator 8, and a red mud slurry with a solid content of 7-10% is prepared;

[0043] The mass percentages of each chemical component in the red mud are SiO 2 13~20%, Al 2 o 3 18~28%, Fe 2 o 3 11~17%, TiO 2 3~5%, CaO 13~20%, MgO 1.5~2.4%, K 2 O 1.2~2.6%, Na 2 O 3~6%;

[0044] b. Inject the red mud slurry made in step a into the red mud pool 2. In order to prevent the separation of gray water, use the agitator 3 to continuously stir, and use the desulfurization circulating pump 4 to transport the red mud slurry in the red mud pool 2 to the desulfurization tower 7...

Embodiment 2

[0047] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0048] In step a: add water and stir evenly through the agitator 8 to prepare a red mud slurry with a solid content of 10-15%;

[0049] Step b: In the boiler flue gas desulfurization process, the volume ratio between the flue gas produced by the boiler and the red mud slurry with a solid content of 10-15% is 1000:3, that is, 1000 cubic meters of flue gas need Pass 3 cubic meters of red mud slurry with a solid content of 10-15%.

Embodiment 3

[0050] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0051] In step a: add water and stir evenly through the agitator 8 to prepare a red mud slurry with a solid content of 15-20%;

[0052] Step b: In the boiler flue gas desulfurization process, the volume ratio between the flue gas produced by the boiler and the red mud slurry with a solid content of 15-20% is 1000:2, that is, 1000 cubic meters of flue gas need Pass 2 cubic meters of red mud slurry with a solid content of 15-20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com