Bainite rail steel with ultra-low aluminium content and high strength and production method thereof

A production method and rail steel technology, applied in the field of rail steel, can solve problems such as hard alumina inclusions, alumina inclusions, and elevation, so as to improve fatigue resistance and service life, ensure the ability to remove inclusions, and improve purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for producing high-strength bainite rail steel with ultra-low aluminum content, comprising the steps of:

[0034] 1) Desulfurization pretreatment: The blast furnace molten iron is desulfurized by spraying magnesium powder combined with slag removal. The desulfurization of molten iron is based on gas as a carrier to spray desulfurizer into molten iron through a spray gun to react with sulfur in molten iron. , so as to achieve the purpose of desulfurization, the reaction product floats into the slag, and the top slag is removed by mechanical equipment to ensure that the sulfur content of the molten iron entering the converter is ≤0.015%.

[0035] 2) Converter smelting: Converter top-bottom compound blowing is adopted, and the oxygen supply intensity is 18000-23000Nm 3 / h, the blowing time is 910s, the final slag basicity is controlled at 3.2, the carbon content at the end of blowing is 0.05%, the phosphorus content at the end is ≤0.012%, the tapping temperature is...

Embodiment 2~8

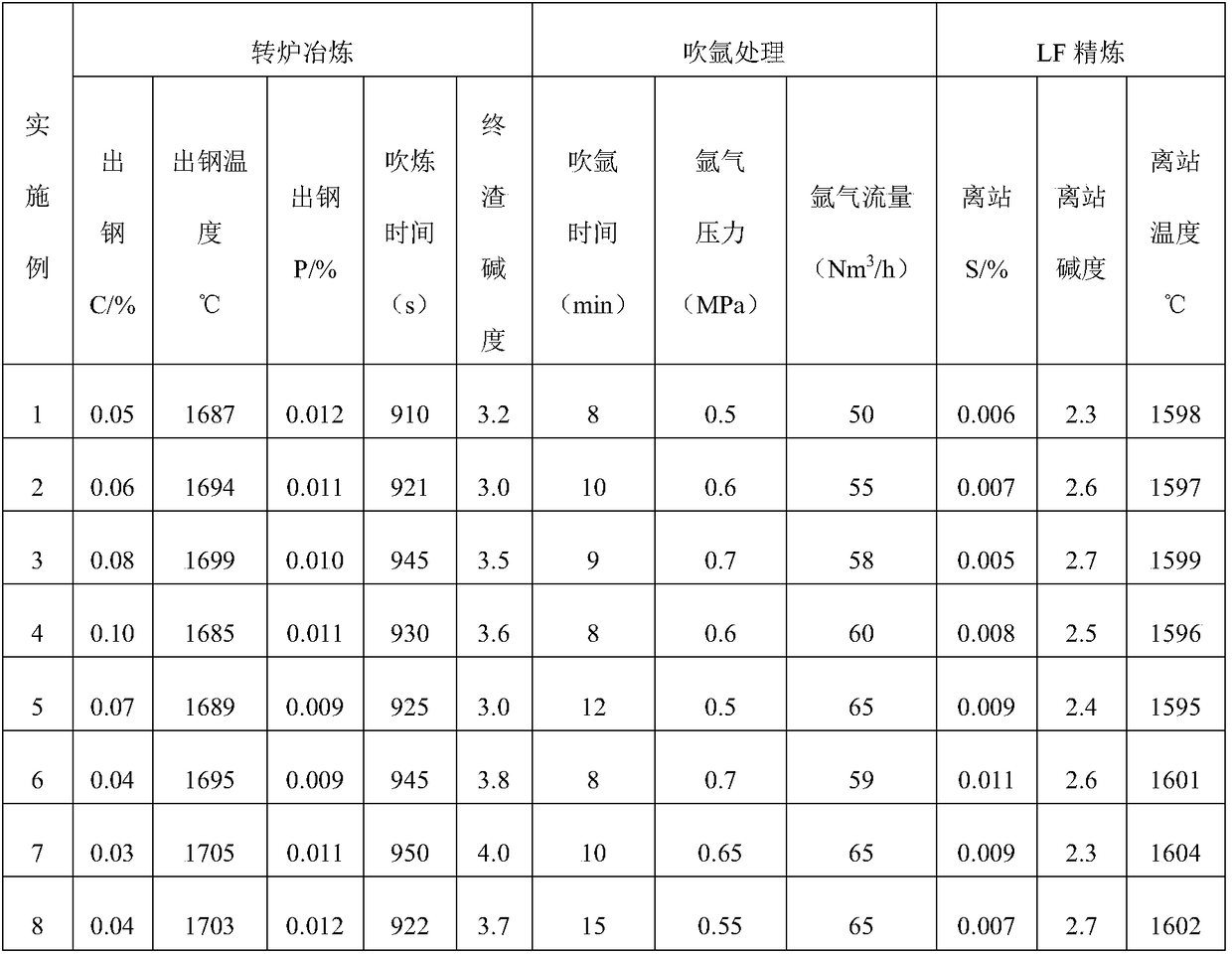

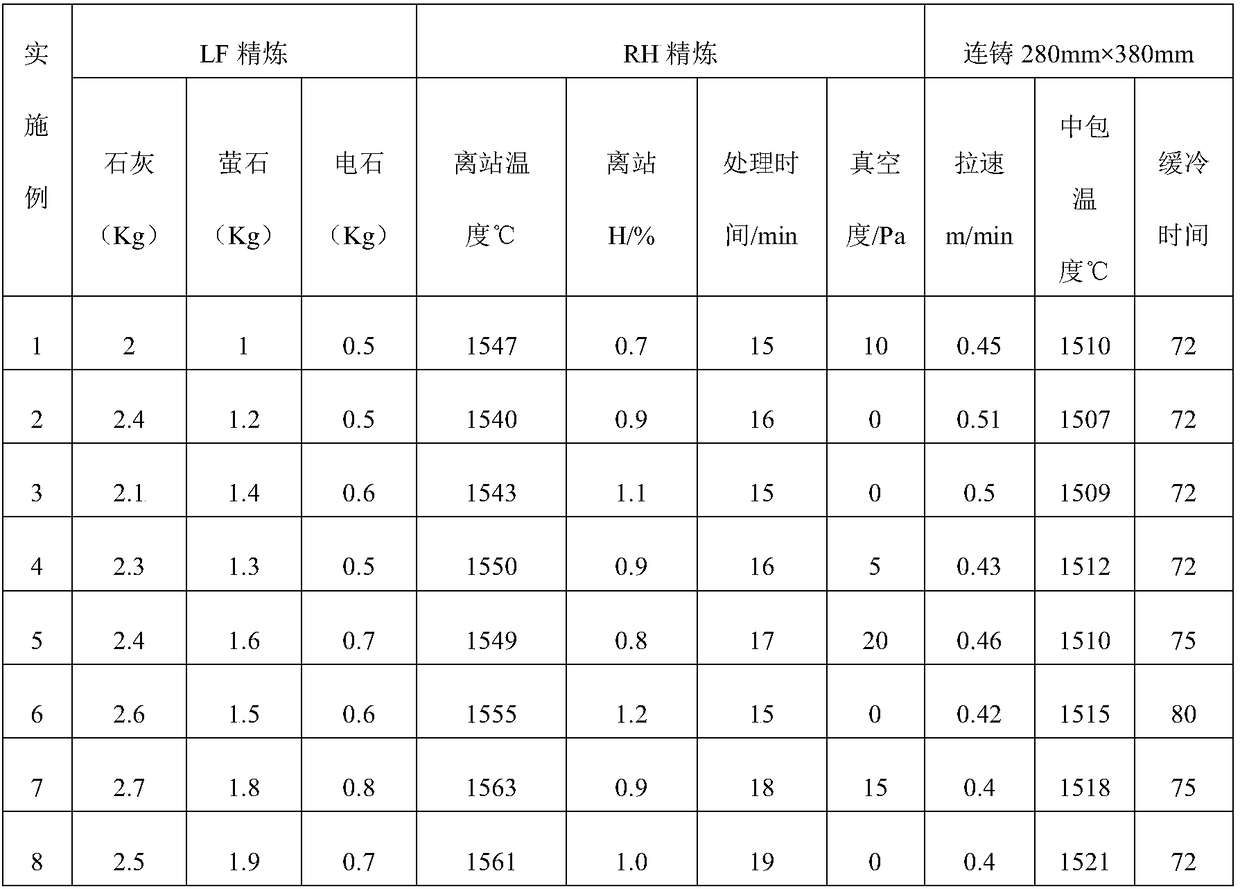

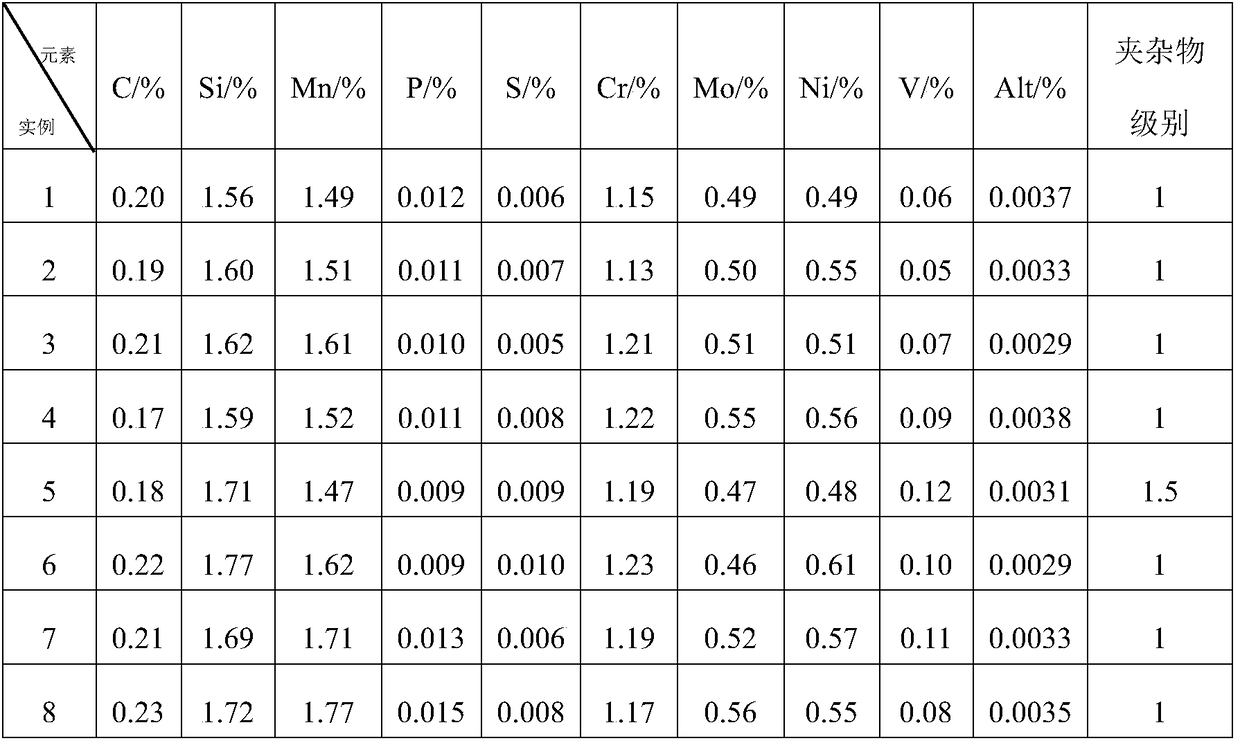

[0043] The implementation process is the same as Example 1 except for the following differences. Table 1 and Table 2 are the main process parameters of each example, and Table 3 is the chemical composition of steel and the control level of alumina inclusions in each example.

[0044] Table 1

[0045]

[0046] Table 2

[0047]

[0048] table 3

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tread hardness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com