High-efficiency lignite low-temperature dry distillation quality-enhancing process by using dry distillation coal gas as heat-carrying medium

A dry distillation gas and dry distillation technology, which is applied in the field of high-efficiency lignite low-temperature dry distillation and upgrading technology, can solve the problems of high sewage treatment costs, high inert components of gas, and large external exhaust pollution, so as to improve the utilization rate of heat energy and save the drying process , the effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

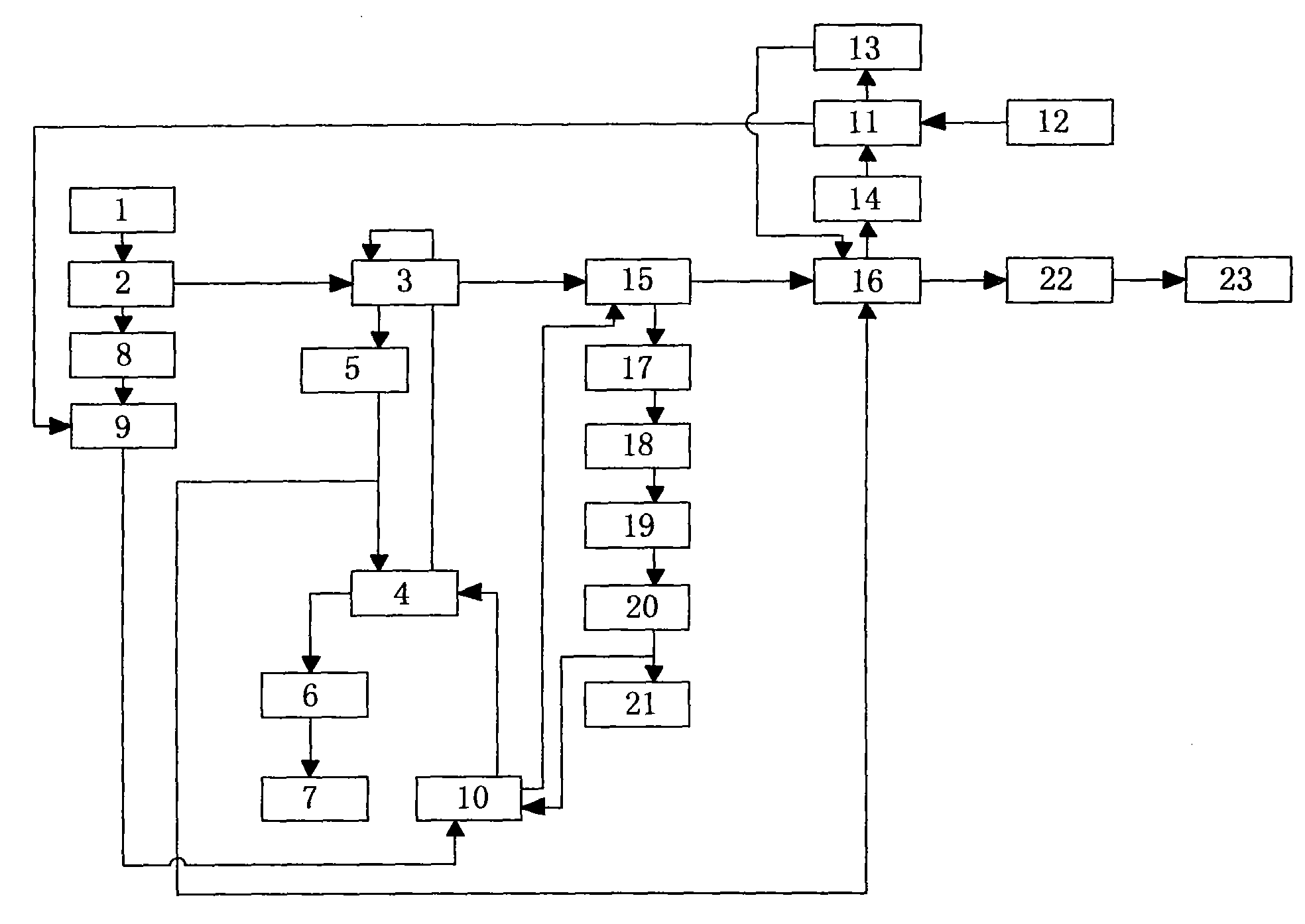

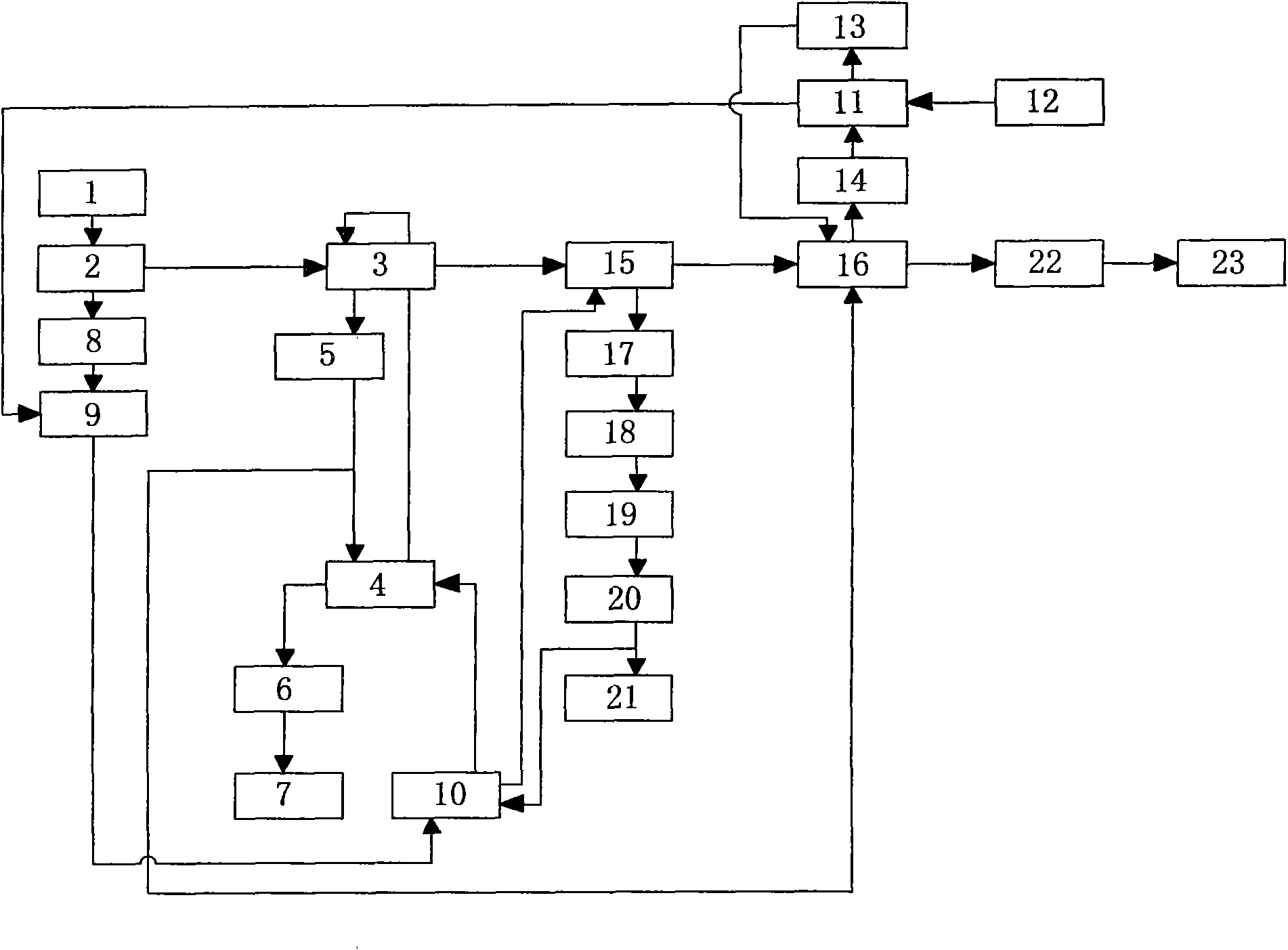

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] Referring to Figure 1, the high-efficiency lignite low-temperature dry distillation upgrading process using dry distillation gas as the heat carrier is divided into coal preparation process, drying process, dry distillation process, heat source process, gas and tar treatment process, and semi-coke cooling and transportation process.

[0032] Coal preparation process: The equipment includes crusher 1, screening bed 2 and supporting coal conveying device. Its main function is to crush raw coal for screening and classification, and transport it to different locations according to different particle sizes. The specific process is: the raw coal enters the crusher 1 for crushing and then sieves on the sieving bed 2, and the coal with a particle size greater than 25mm returns to the crusher 1 to continue crushing; the coal with a particle size between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com