Device for manufacturing biological carbon

A technology of biochar and driving device, which is applied in the direction of biofuel, coke cooling, special form of dry distillation, etc., and can solve problems that have not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

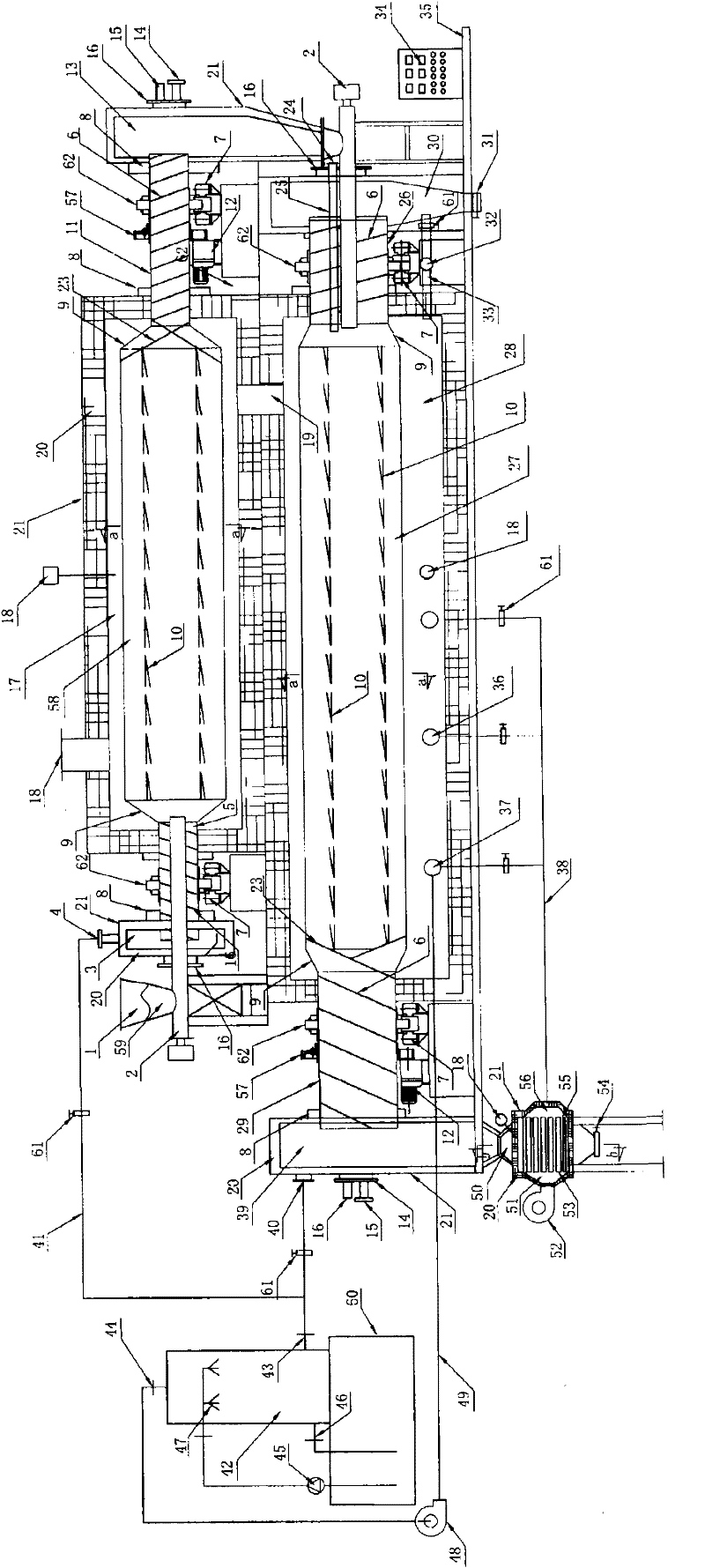

Method used

Image

Examples

Embodiment 1

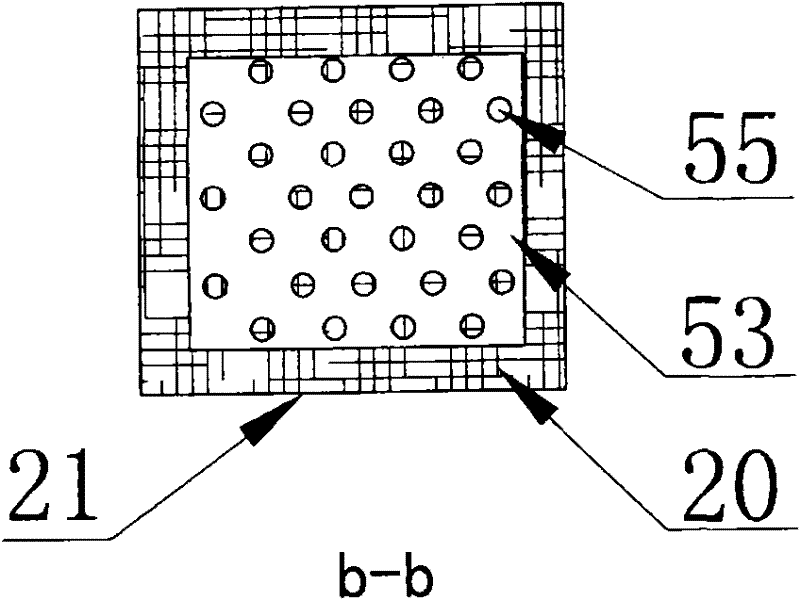

[0110] This embodiment produces biochar. The biomass raw material 59 is cow dung from a cattle farm. The cow dung is preheated, carbonized, activated, and cooled to make biochar. 3 tons of cow dung are processed every day.

[0111] The preheating chamber 58 is located in the hot flue gas chamber 17, and both ends of the preheating chamber 58 are connected with the discharge drum 11 and the feed drum 5, wherein the discharge drum 11 is connected with the intermediate silo 13, and a sealing device 8 is installed at the connection , The feed drum 5 is connected to the gas collection chamber 3, and a sealing device 8 is installed at the connection. The mixed gas outlet 4 of the gas collection chamber 3 is connected with the air inlet 43 of the spray washing cooling tower 42 through the mixed gas pipe 41,

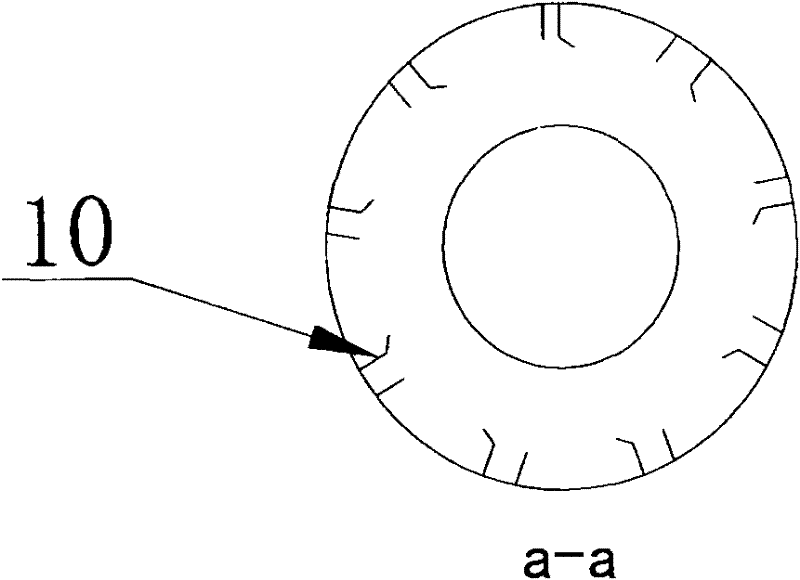

[0112] The length of the preheating chamber 58 is 2 meters, and the diameter is 0.8 meters. The filling rate of raw materials in the preheating chamber 58 is 45% of the volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com