Limit controller of flame cutting vehicle

A flame cutting, vehicle controller technology, applied in position/direction control, control system, computer control, etc., can solve the problems of difficult on-site wiring, inconvenient installation and maintenance, and take up a lot of time, so as to reduce the labor intensity of workers and ensure safe production. High coefficient, the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

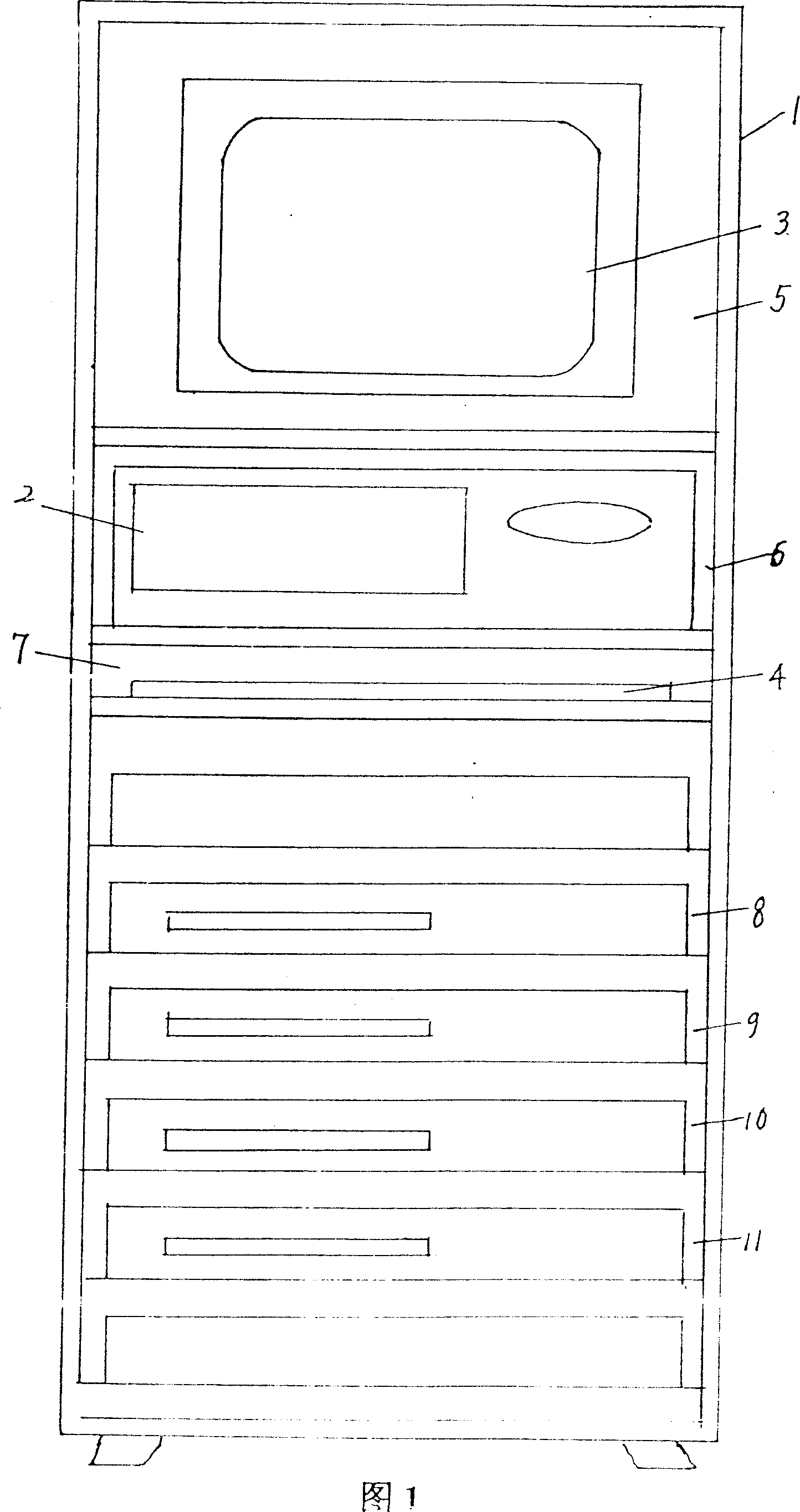

[0015] The flame cutting controller includes a cabinet 1, a monitor 3, a host 2, a keyboard and a mouse 4 and a control part. The monitor is installed in the monitoring room 5, and the main engine is installed in the main machine room 6. The keyboard and mouse 4 are installed in the keyboard compartment 7 . The control part includes 4 flow control display modules, and each flow control display module includes various detection control circuits, length display communication control circuits, frequency converter frequency display and output control circuits.

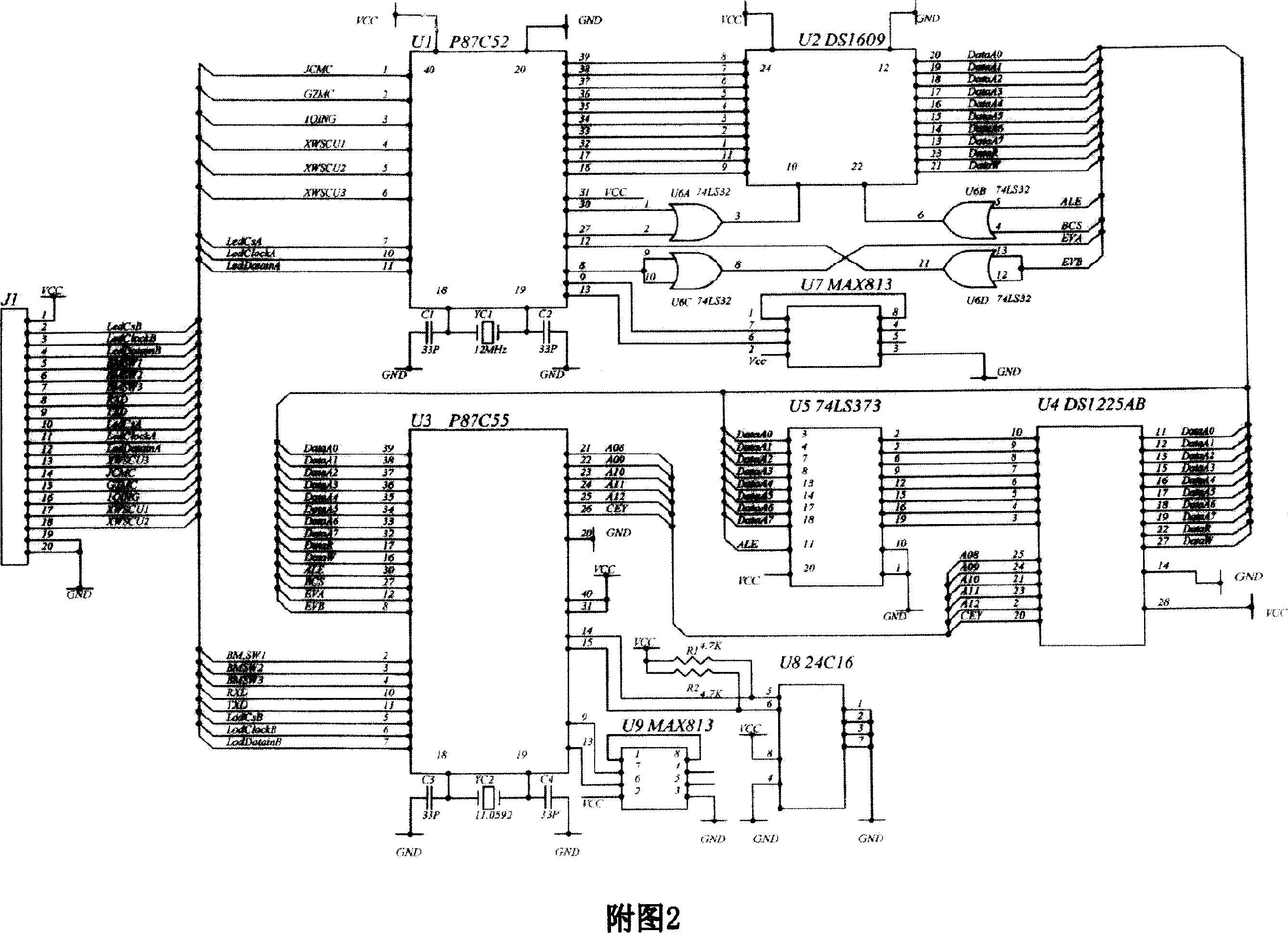

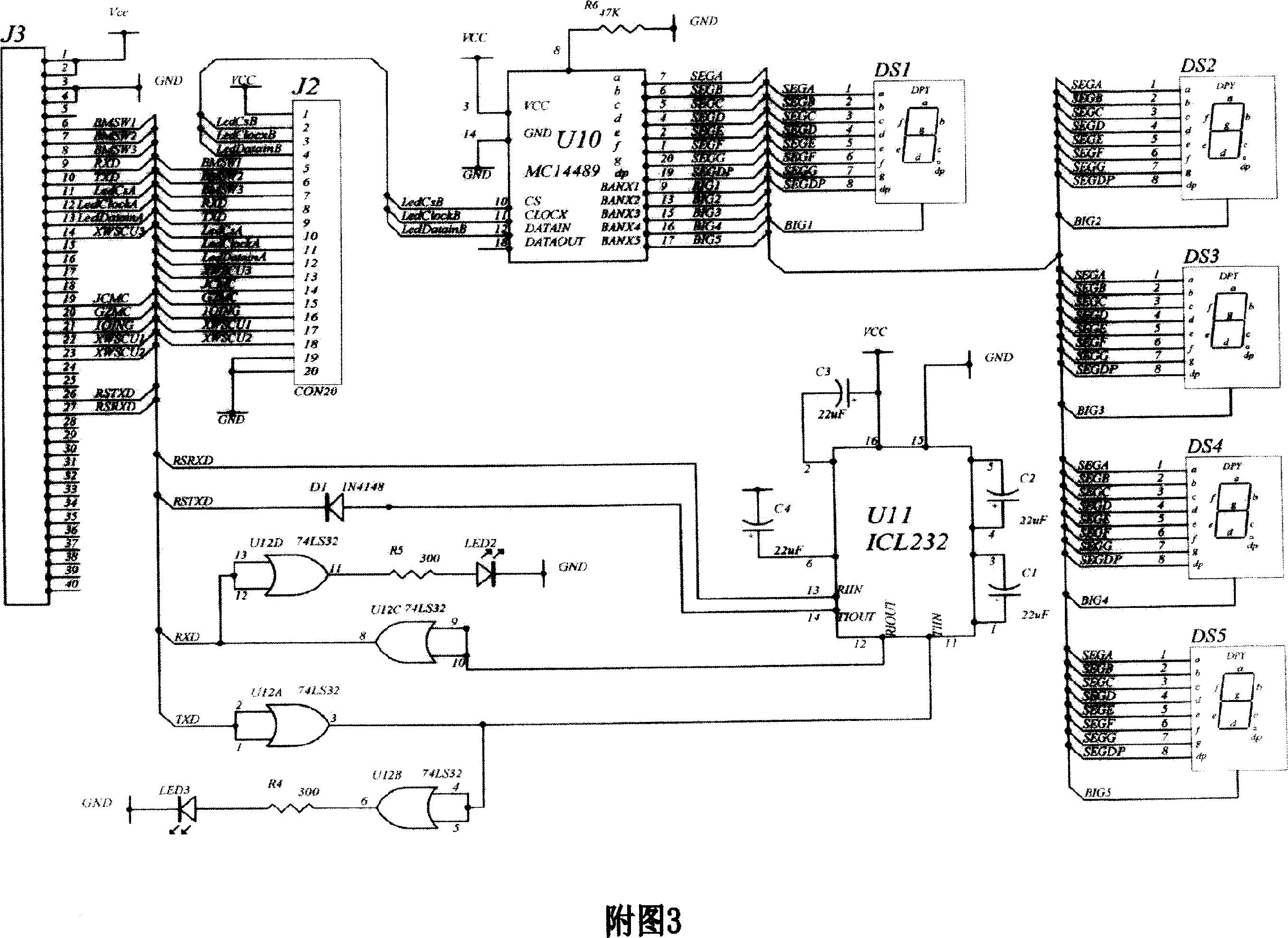

[0016] The work detection control circuit includes the integrated circuit U 1 , U 2 , U 3 , U 4 , U 5 , U 6 , U 7 , U 8 , U 9 and U 6A , U 6B , U 6C , U 6D Connector J 1 . u 1 It is used as work control for the integrated circuit P87C52. u 2 For the integrated circuit DS1609, used for data exchange, U 3 For the integrated circuit P87C52 used for communication control, U 4 It is used as control for the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com