Unattended system and method for aggregate crushing equipment

A technology for crushing equipment and aggregates, which is applied in the field of sand and gravel aggregate processing, can solve the problems of inability to realize the pre-testing of products, inability to guarantee the safety of equipment and products, quality, and insufficient detection ability of intermediate products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

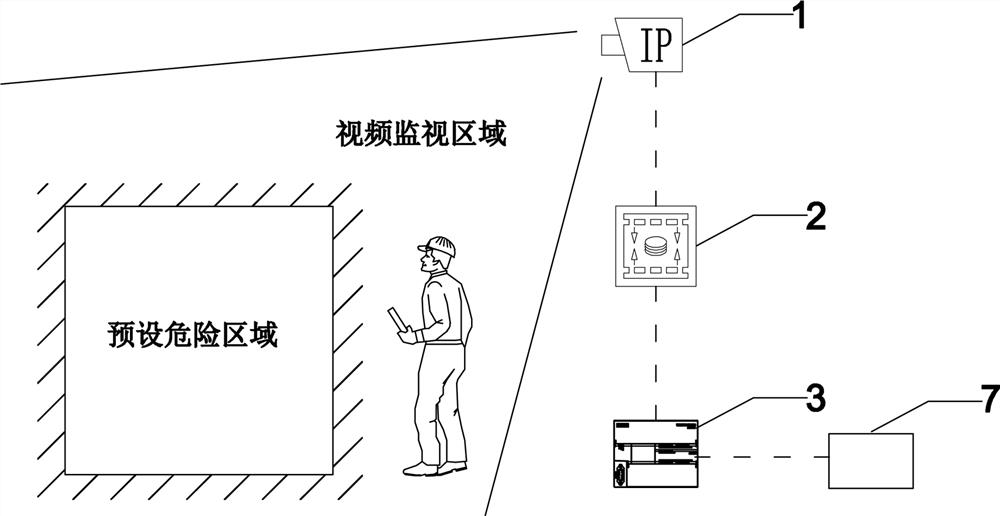

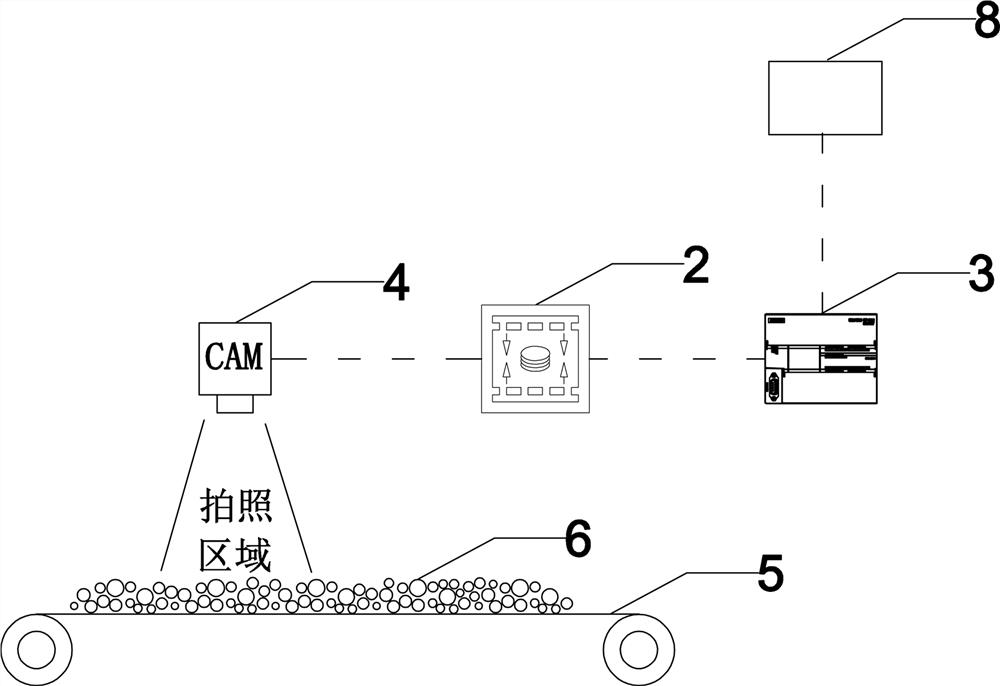

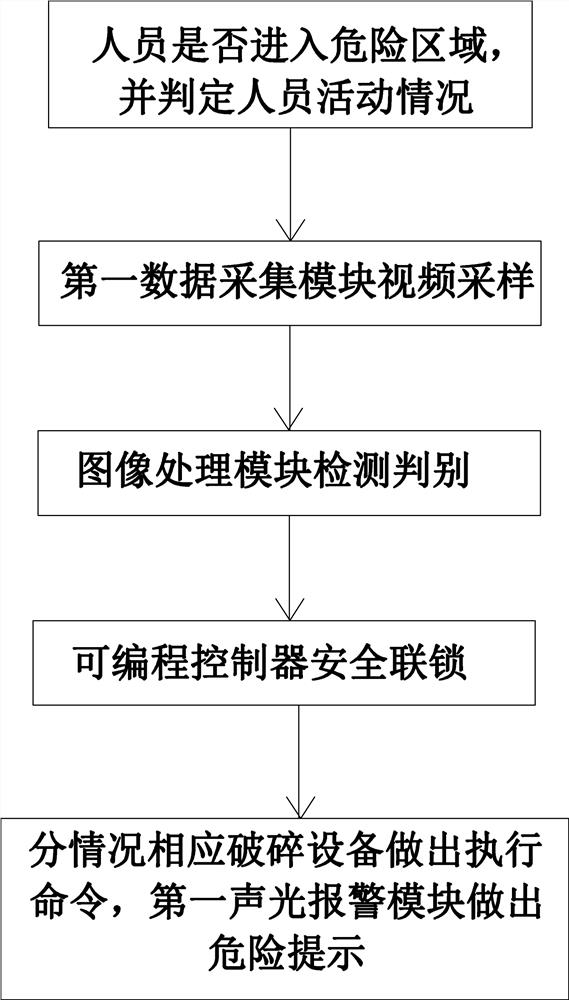

[0037] An unattended system for aggregate crushing equipment, including a dangerous area monitoring part, a discharge size monitoring part, an image processing module 2 and a programmable controller 3;

[0038] The dangerous area monitoring part includes a first data acquisition module 1, an image processing module 2, a programmable controller 3 and a first sound and light alarm module 7 for real-time video monitoring of preset dangerous areas, and the first data acquisition module 1 is set above the preset dangerous area and covers the preset dangerous area, the first data acquisition module 1 is connected to the image processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com