Non-contact three-dimensional thermal displacement detection system and application thereof

A detection system, non-contact technology, applied in the field of machinery, can solve the problems of discontinuous data, low degree of automation, poor real-time performance, etc., to achieve the effect of improving the level of intelligence, winning economic benefits, and improving the coefficient of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

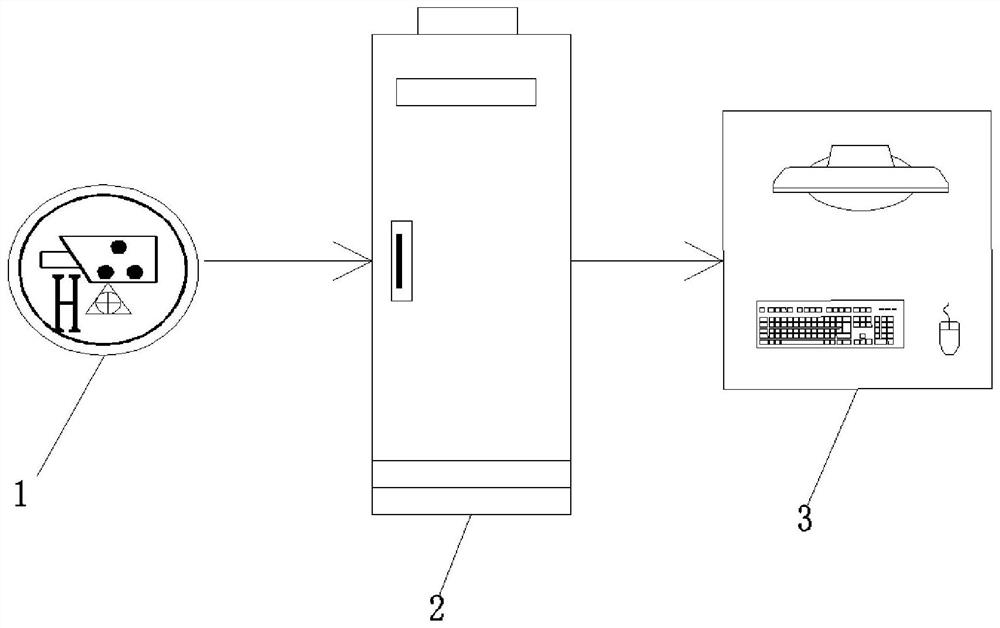

[0021] Such as figure 1 As shown, the present embodiment provides a non-contact three-dimensional thermal displacement detection system, including a binocular camera, a laser rangefinder 1, a vision processing cabinet 2 and a computer control system 3, and a pair of displacement of the binocular camera and the laser rangefinder 1 The signal is collected, and then the collected signal is transmitted to the vision processing cabinet 2, and the vision processing cabinet 2 transmits the signal to the computer control system 3.

[0022] Preferably, the computer control system 3 includes a host computer and a display connected to the host computer.

[0023] Preferably, the non-contact three-dimensional thermal displacement detection system further includes an alarm system connected to the computer control system 3, and when the parameters received by the computer control system 3 exceed the preset range, the alarm system starts to work.

[0024] Preferably, the alarm system include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com