A kind of cellulose fiber cold fixation color digital printing method

A cellulose fiber and digital printing technology, applied in the field of textile printing and dyeing, can solve the problems of uneven color development of printed patterns, unstable steam pressure, uneven temperature distribution, etc., achieve bright colors, improve safety production coefficient, and three-dimensional effect strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

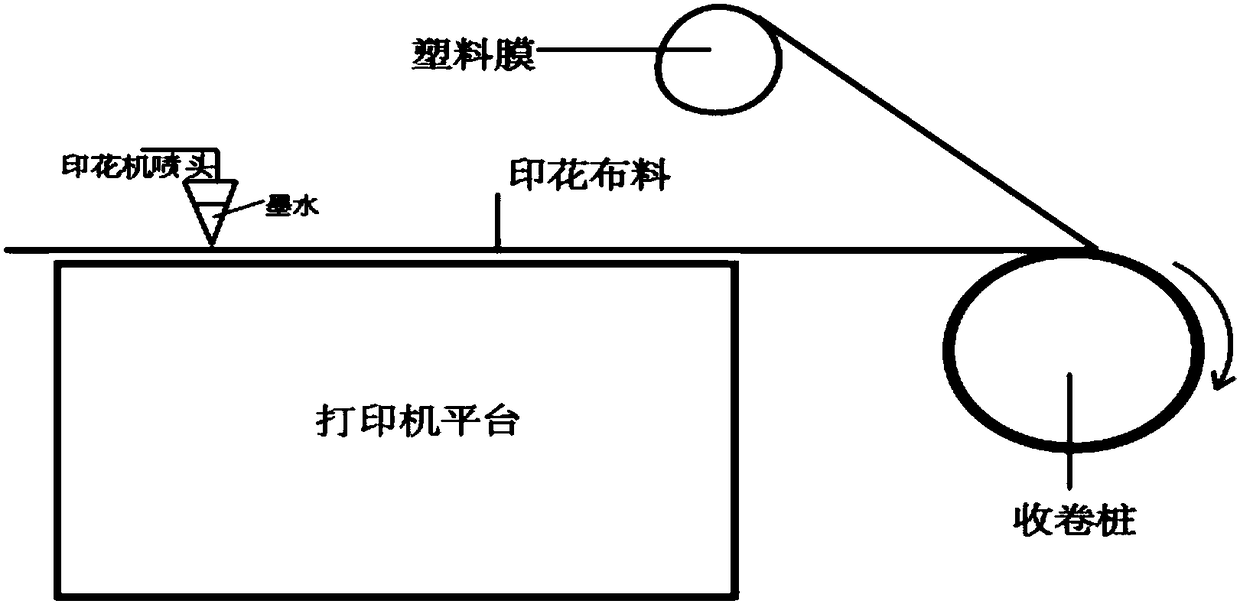

[0034] Such as figure 1 Shown, a kind of cellulose fiber cold fixation color digital printing method comprises the steps:

[0035] (1) Select reactive dye ink; the raw materials of reactive dye ink are as follows by weight percentage: reactive dye 5-20%, water retaining agent 10-35%, surfactant 1-5%, film forming agent 1-5%, moisture absorption Antiseptic 1-3%, fungicide 1-2%, descaling agent 0.1-2%, buffer 0.1-3%, and the balance is water. The reactive dye is one or more of X-type reactive dyes, KN-type reactive dyes, and P-type reactive dyes. Specifically, X-3B brilliant red, X-6G bright yellow, X-7G bright yellow, KN-BGFN emerald Blue, X-B Brilliant Blue, P-WN Black; the water retaining agent is one or more of glycerol, diethylene glycol, polyethylene glycol 400, diethylene glycol butyl ether, N-methylpyrrolidone, The surfactant is one or more of Pingpingjia, surfynol 104E, surfynol 465, the film-forming agent is one or more of polyvinylpyrrolidone, carboxymethyl cellulos...

Embodiment 1

[0041] Reactive Dye Ink Preparation

[0042] The components and weight ratio of reactive dye ink are: 20% reactive dye, 30% water retaining agent, 2% surfactant, 2% film forming agent, 3% hygroscopic agent, 1% bactericide, 2% descaling agent, buffer Agent 0.5%, the balance is water.

[0043] The preparation method is as follows: first purify and concentrate the purchased commercially available reactive dyes, use nanofiltration to desalt, control the inorganic salt content of the purified dye to be ≤0.05%, and set aside; then add a specified amount of desalted Ionized water, start the mixer, and add a specified amount of surfactant at a speed of 600 rpm. Raise the temperature to 65°C, increase the speed of the mixer to 1300 rpm, add the specified amount of the above-mentioned purified reactive dye, and stir until the dye is completely dissolved. Leave it to stand for 1 hour, then filter through a water-based membrane filter with a pore size of 1 micron to obtain a reactive dy...

Embodiment 2

[0049] Reactive Dye Ink Preparation

[0050] The components and weight ratio of reactive dye ink are: 10% reactive dye, 35% water retaining agent, 1% surfactant, 1% film forming agent, 2% hygroscopic agent, 1% bactericide, 2% descaling agent, buffer Agent 0.5%, the balance is water.

[0051] The preparation method is as follows: first purify and concentrate the purchased commercially available reactive dyes: use nanofiltration to desalt, control the inorganic salt content of the purified dye to be ≤0.05%, and reserve; then add a specified amount of desalted Ionized water, start the mixer, and add a specified amount of surfactant at a speed of 600 rpm. Raise the temperature to 70°C, increase the speed of the mixer to 1300 rpm, add the specified amount of the above-mentioned purified reactive dye, and stir until the dye is completely dissolved. Leave it to stand for 1 hour, then filter through a water-based membrane filter with a pore size of 1 micron to obtain a reactive dye ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com