Hand-operated expansion mechanism for unreeling machine for stainless steel strip coil

A technology of stainless steel strip and unwinding machine, which is applied in the field of online welding and forming of stainless steel pipes, and can solve the problems of easy retraction, small expansion and contraction stroke, and high manual strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

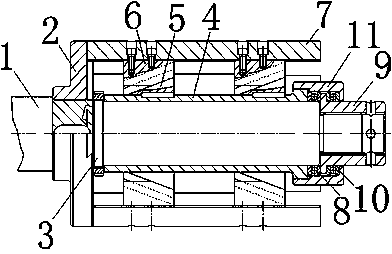

[0014] The specific implementation manner of the present invention will be further described in detail below by describing the preferred embodiments with reference to the accompanying drawings.

[0015] as attached figure 1 As shown in the figure, a manual shrinking and expanding mechanism of a stainless steel coil unwinding machine includes a transmission shaft 1, a sliding sleeve 4 and an arc plate 7. The transmission shaft 1 is made of high-quality tool steel after quenching and tempering, and bears the Connection drive and load-bearing steel belt coils. Sliding sleeve 4 is slidably arranged in the middle part of transmission shaft 1, and one end of transmission shaft 1 is connected with the unwinding machine reducer, and the end of transmission shaft 1 is provided with disc slider 2 by a flat key. In order to ensure the working stability of the disc slider, the transmission shaft 1 is provided with a round nut 3 for locking the disc slider 2 . The other end of the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com