Roll vacuum heat treatment cleaning equipment

A technology of vacuum heat treatment and cleaning equipment, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve many problems, such as cleaning utensils, rubber gloves, cleaning liquid, cotton yarn, waste, cleaning liquid Serious volatilization and other problems, to achieve the effect of improving the environmental safety production coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

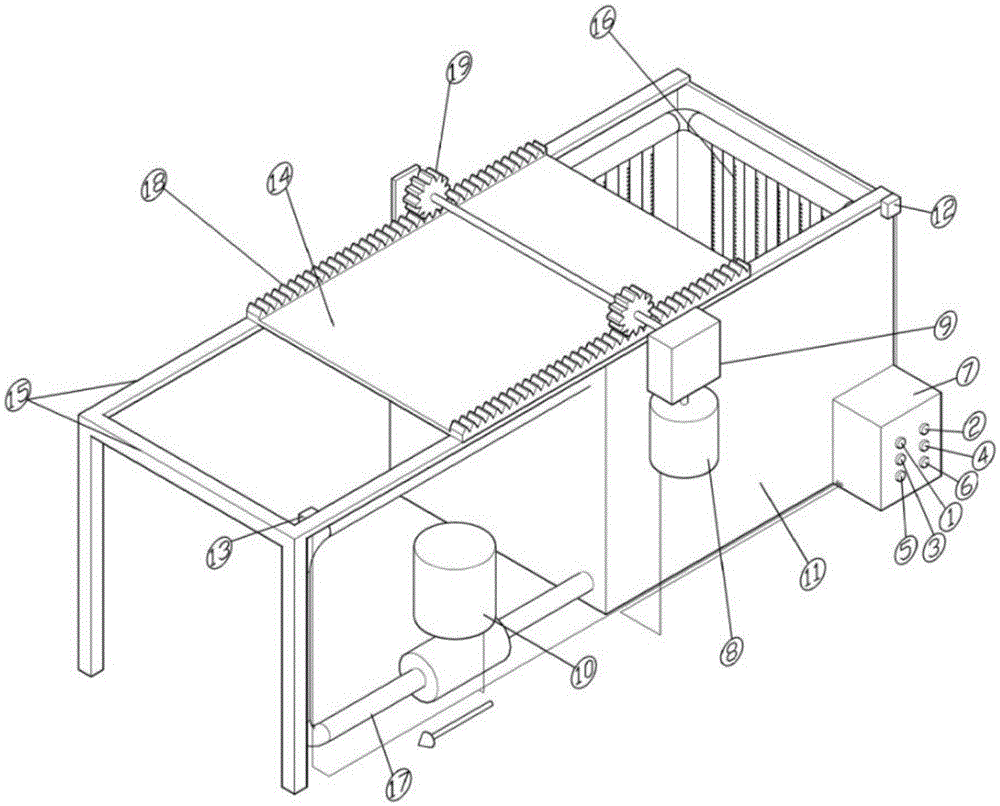

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

[0023] Heat treatment cleaning equipment, including a cleaning box 11, a box cover 14 capable of sliding back and forth along its surface is provided on the top of the cleaning box 11, and a circle of cleaning liquid circulation pipe 17 is provided on the top of the cleaning box 11 , the cleaning liquid circulation pipe 17 communicates with the cleaning liquid outlet of the cleaning tank through an external pipeline, and is connected with some cleaning liquid spout pipes 16 arranged vertically downward on the cleaning liquid circulation pipe 17; The spout pipe is provided with such as dry small holes.

[0024] Described cleaning box 11 is provided with track 15, and box cover is installed on the track 15, is fixed with rack 18 on the cover, and described rack cooperates with gear 19, and the input end of described gear and speed reducer 9. The speed reducer 9 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com