Method for integrated comprehensive management of gas in low-permeability single coal bed

A technology for comprehensive treatment of coal seam gas, which is applied in the field of comprehensive treatment of low-permeability single coal seam gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be described in detail below in conjunction with specific conditions and accompanying drawings.

[0013] The present invention is implemented by the following steps in implementation:

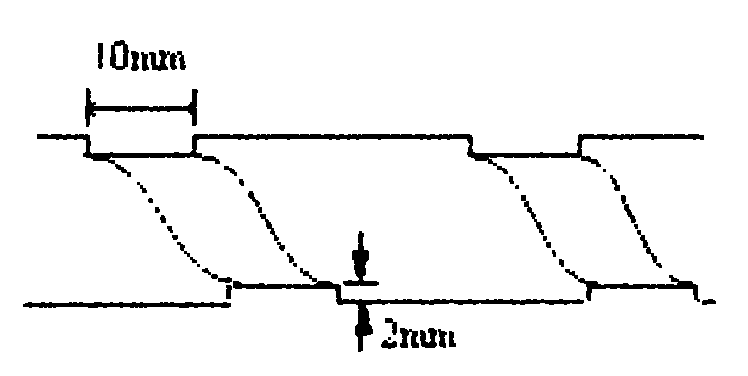

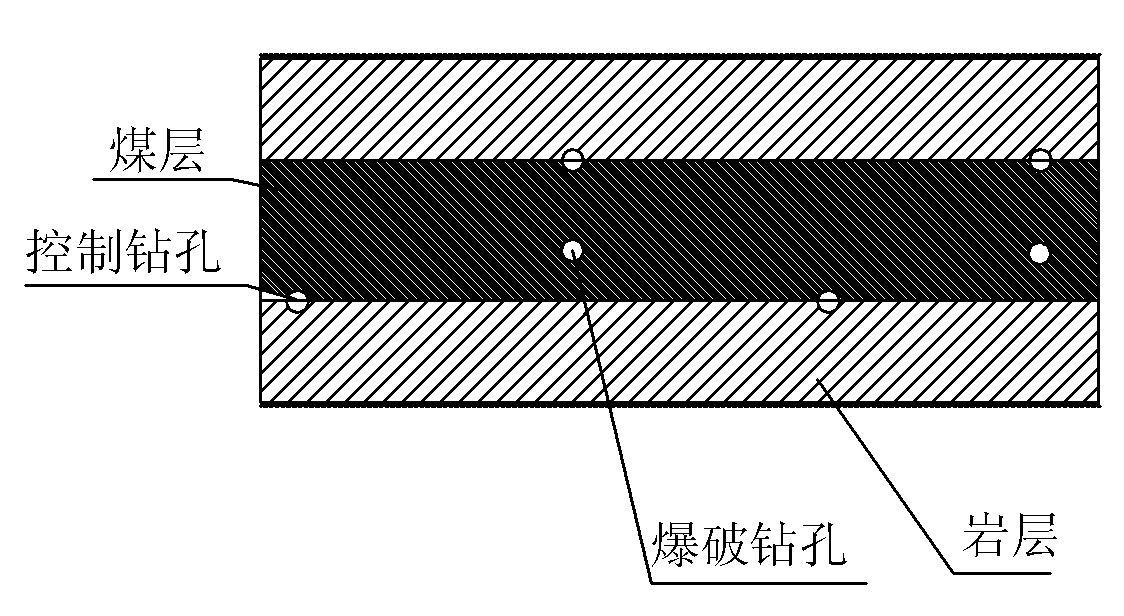

[0014] (1) Drilling, the method is to use a drilling rig with a torque of 2000-6200KN to improve the drilling construction capacity, and use a double-line or a triangular drill pipe. The drill pipe is evenly distributed with grooves with a depth of 2mm and a width of 10mm. The drill pipe drilling can effectively solve the phenomenon of drill pipe clamping caused by hole collapse and spray hole during the drilling construction process. The structure of the drill pipe is as follows: figure 1 shown.

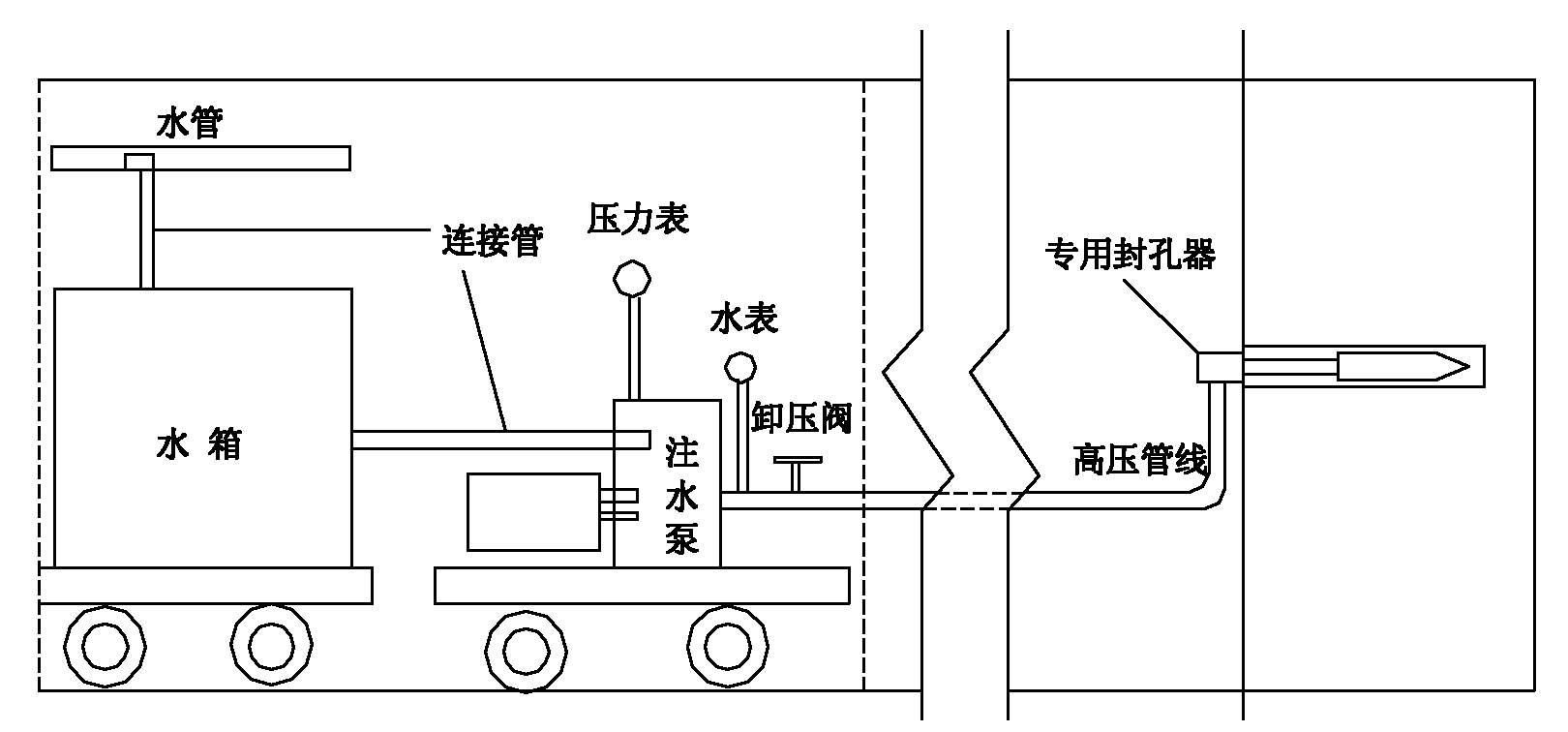

[0015] (2) The hydraulic fracturing of the coal body increases the permeability. The method is to seal the hole with a ¢50mm seamless steel pipe, cement mortar, and polyurethane after the hole is drilled. The length of the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com