A low-permeability coal seam supercritical carbon dioxide permeability enhancement system and method

A carbon dioxide, supercritical technology, applied in pipeline systems, container filling methods, container discharge methods, etc., can solve the problems of low permeability of coal seams, difficult to popularize and apply, etc., to improve the permeability of coal seams, strong controllability, structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

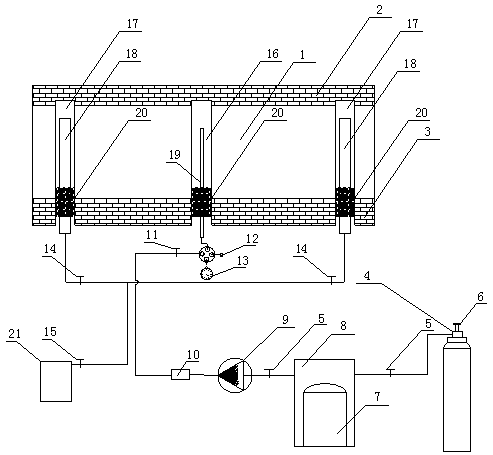

[0027] Such as figure 1 The shown low-permeability coal seam supercritical carbon dioxide permeation enhancement system includes a drainage pipe 18 and an injection pipe 19 arranged in parallel, and a hole sealer 20 is sleeved on the drainage pipe 18 and the injection pipe 19 .

[0028] A drainage device 21 is connected to the outer end of the drainage pipe 18 through a drainage pipeline, and a drainage shut-off valve 14 and a drainage main shut-off valve 15 are sequentially arranged between the drainage pipe 18 and the drainage equipment 21 .

[0029] The outer end of the injection pipe 19 is sequentially connected with a gas injection shut-off valve 11, a gas regulator 10, a supercritical carbon dioxide injection pump 9, a constant temperature box 8 and a carbon dioxide gas tank 4 through the injection pipeline. The high pressure buffer tank is arranged in the constant temperature box 8 7. A pressure reducing valve 6 is installed on the carbon dioxide tank 4 . There are two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com