Method for deep hole blasting in coal face

A coal mining face and deep-hole blasting technology, which is applied in blasting and other directions, can solve the problems of large charge impact disaster, blasting construction danger, and not being widely used, so as to achieve good blasting effect, reduce risk, and have strong pertinence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments.

[0021] The mining depth of Pingdingshan coal mine is deep, the coal seam has high gas content, the coal seam is relatively soft, the stress concentration is obvious, and the risk of outburst is prone to occur. Based on the coal seam geological characteristics of the No. Explanation.

[0022] A deep hole blasting method in a coal mining face, comprising the following steps:

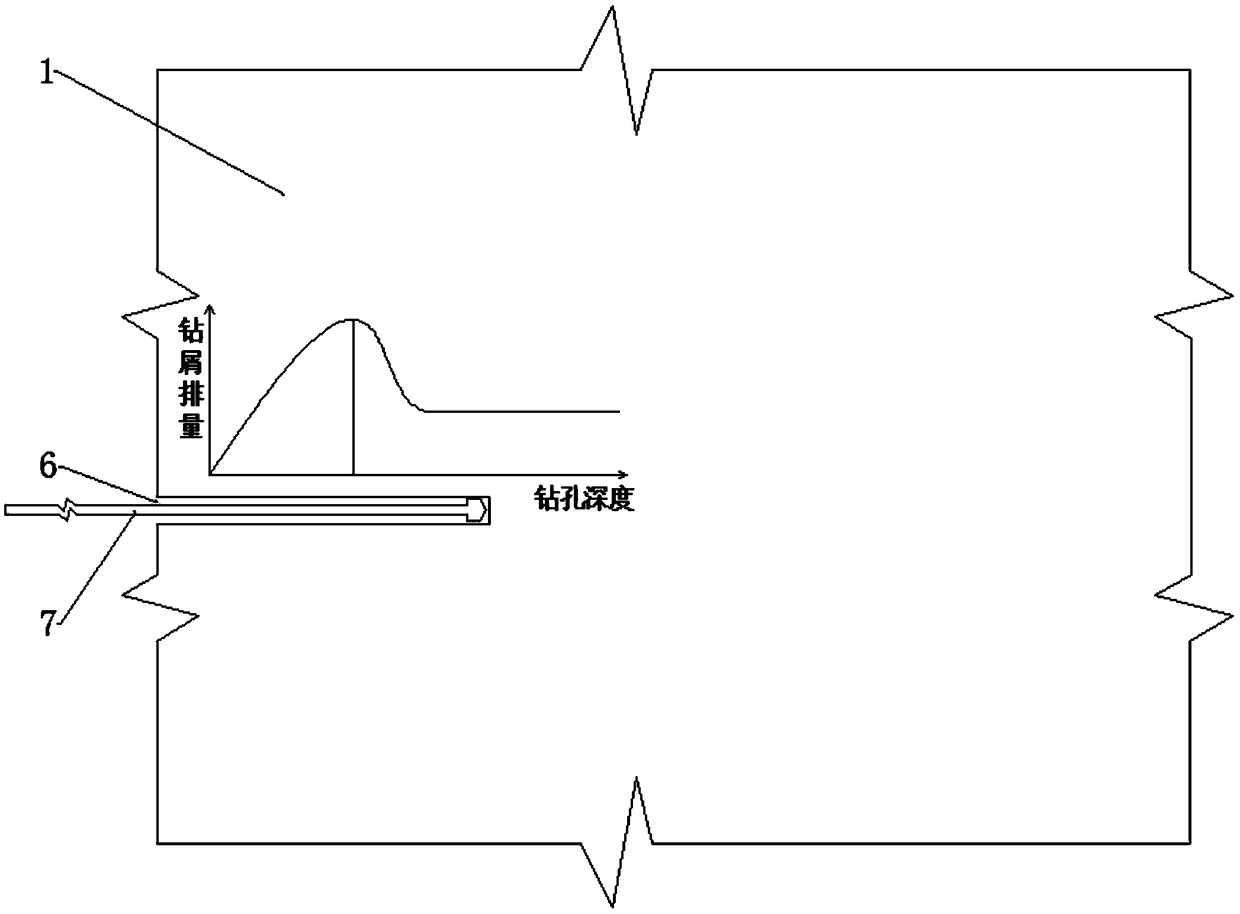

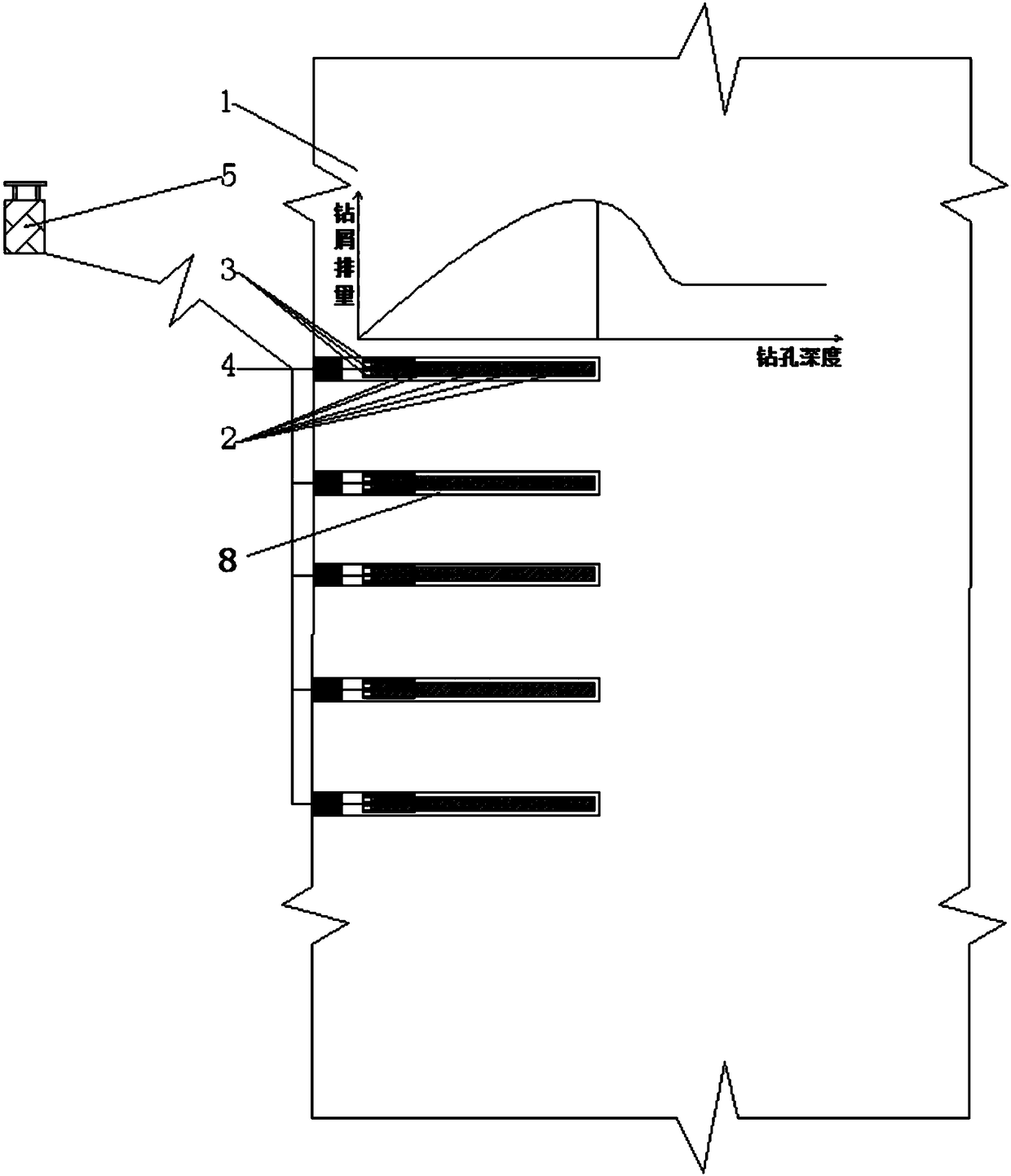

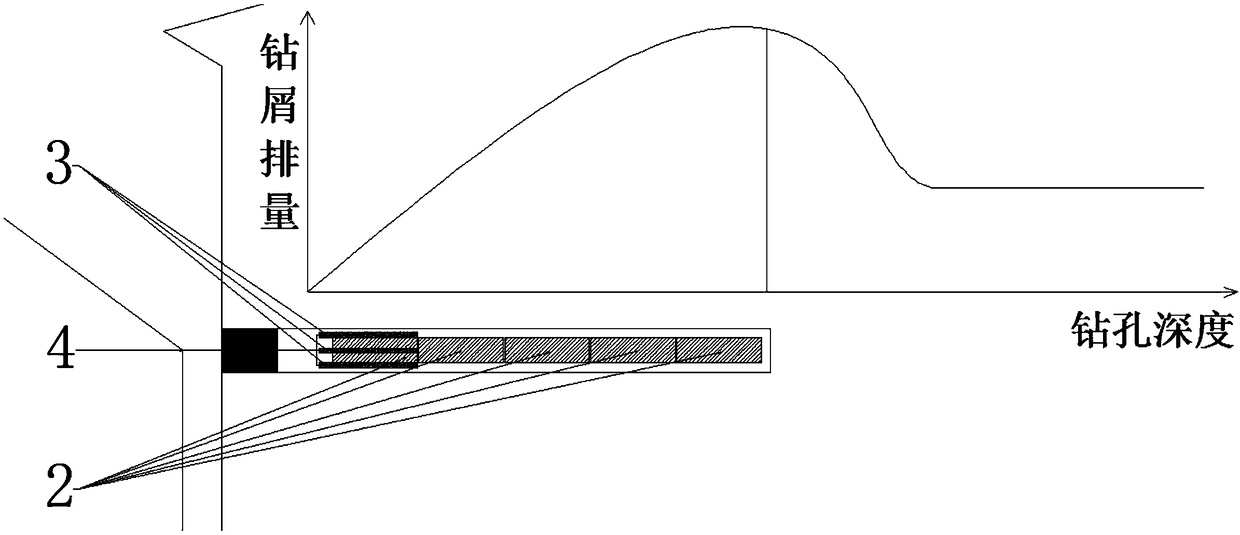

[0023] Such as figure 1 As shown, a. Firstly, construct the test hole 6 on the working face 1 of No. 9-10-21050 of No. 8 Coal Mine, the test hole 6 is perpendicular to the wall surface, and test the discharge of drilling cuttings during the drilling operation of the drill pipe 7 Keep the drilling speed of the drill pipe 7 as a fixed value V. At this time, if the drilling process encounters an increase in coal and rock stress, the amount of cuttings discharged per unit time during the drilling proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com