Coal raking machine and coal mining method utilizing coal raking machine

A technology of coal machine and scraping head, which is applied in the directions of earth-moving drilling, slitting machinery, propulsion, etc., can solve the problems of difficult mining of steeply inclined coal seams, easy lodging of supporting equipment, difficult roof support, etc., and achieve unmanned mining. Increased effect, fewer coal miners, simpler structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

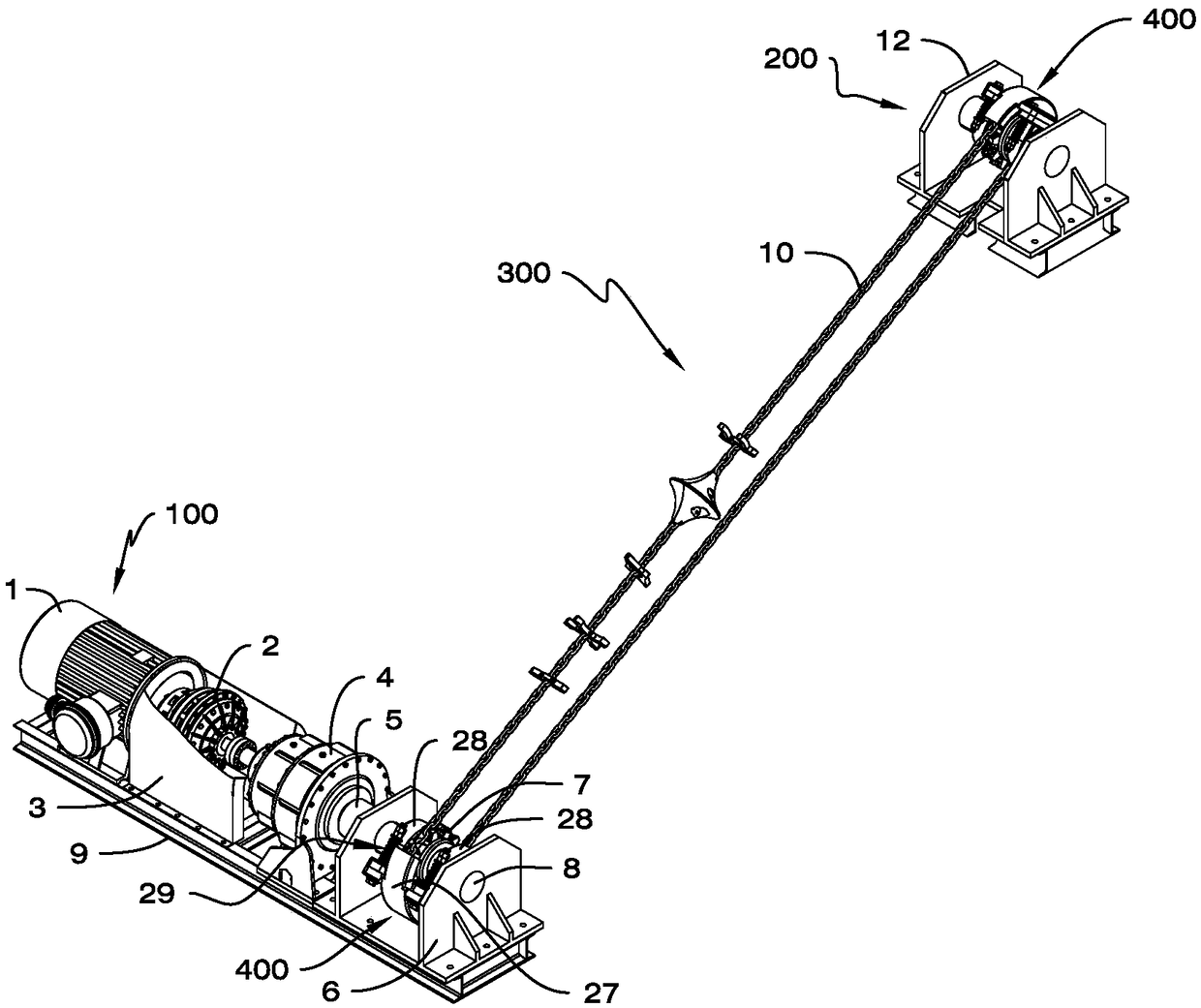

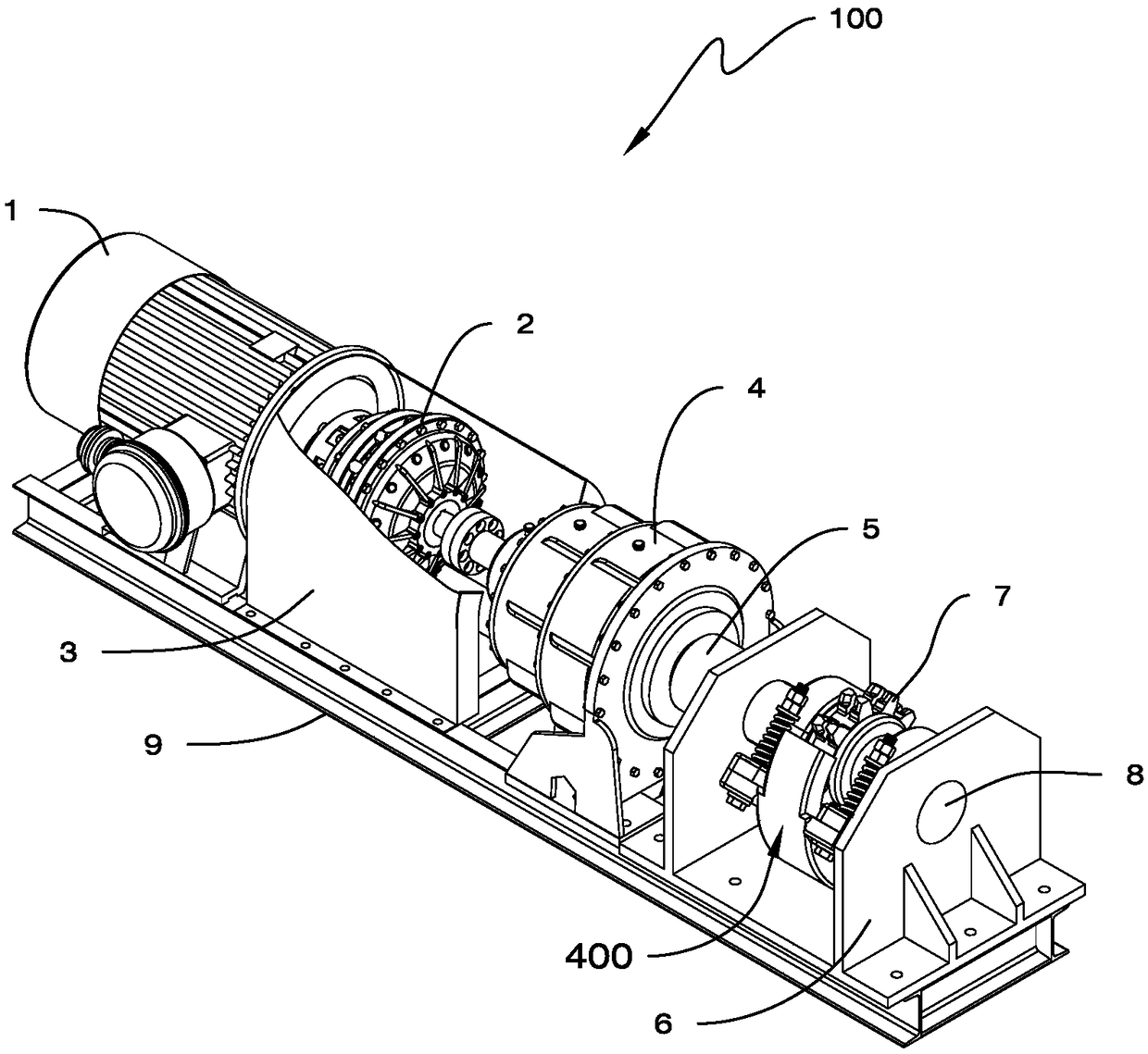

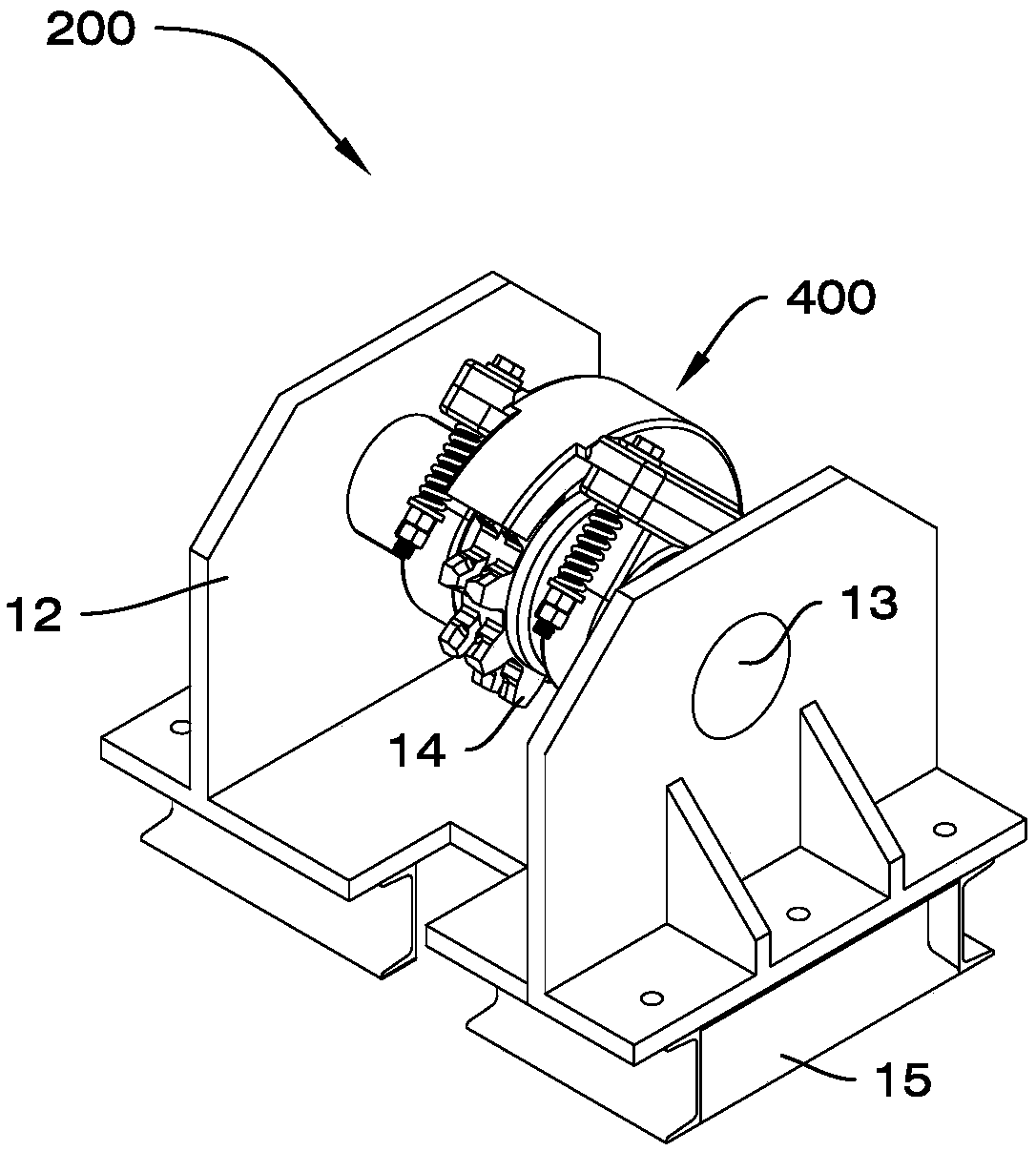

[0037] like Figure 1 to Figure 4 and Figure 10 , Figure 11 As shown, the coal scraper of the present invention includes a driving part 100 , a driven part 200 , a transmission link part 300 , and a chain sprocket engaging and pressing device 400 . The active part 100 includes a power output part 1 , a fluid coupling 2 , a transmission 4 , and a drive sprocket 7 which are connected to an external frequency conversion control system and connected in sequence from left to right through a shaft or coupling 5 . The power output part 1 and the drive sprocket 7 are connected by a hydraulic coupling 2 and a shaft coupling 5, which ensures power output and overload. The power output part 1 is an electric motor or a hydraulic system. The dual hydraulic system of the coal raking machine can either directly use the emulsion system in the coal mine to provide the power source, or use its own hydraulic oil system. The hydraulic coupler 2 is provided with a protective cover 3, which no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com