High-pressure hydraulic tunneling, pressure releasing and protrusion removing method for upper drainage roadway

A high-pressure water pump and hydraulic technology, applied in earthwork drilling, gas discharge, safety devices, etc., can solve problems such as difficult to achieve outburst prevention effect, high drilling tool damage rate, short hole length, etc., to improve the underground working environment , relieve stress and pressure, enhance the effect of coal hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with an embodiment (accompanying drawing):

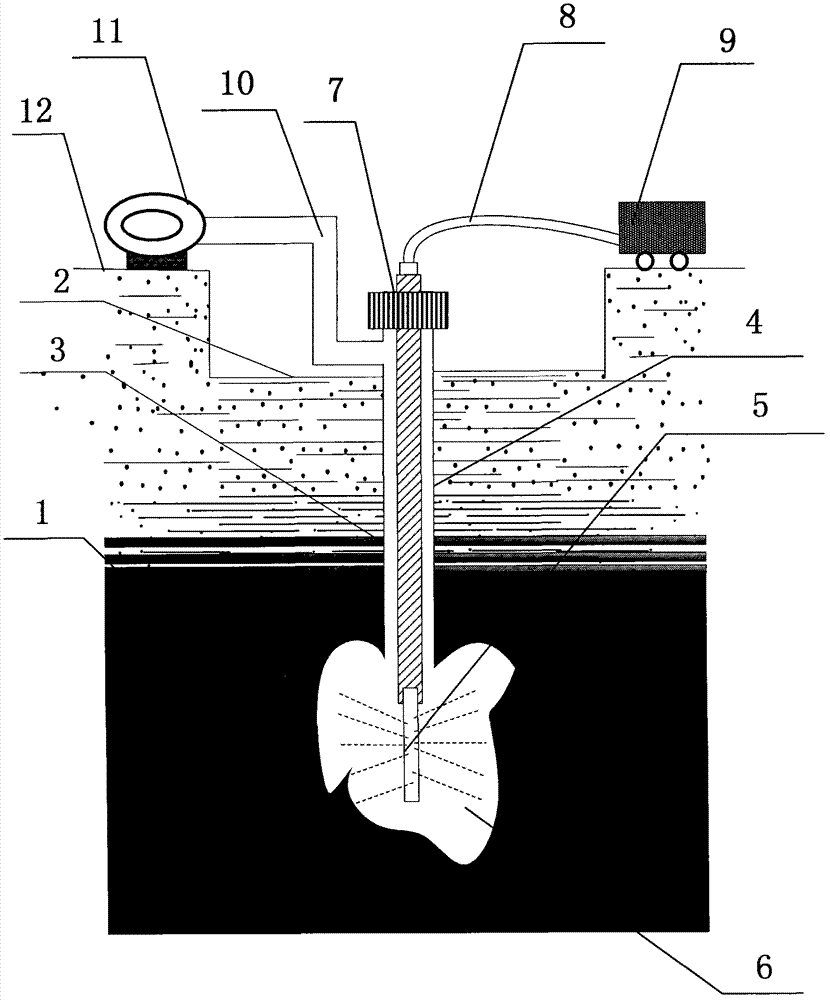

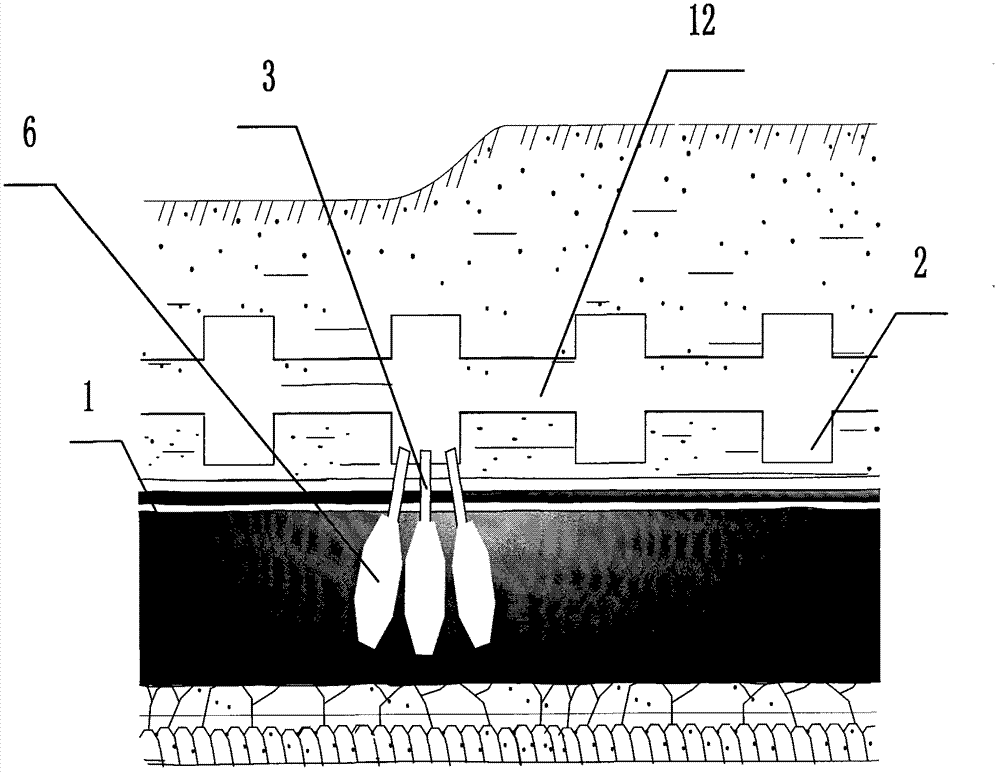

[0022] Such as figure 1 , figure 2 As shown, the method for pressure relief and outburst elimination of high-pressure hydraulic hole digging in the upper pumping lane of the present invention, the specific implementation steps are as follows:

[0023] (1) In the upper pumping roadway 12 of the coal seam 1 in the outburst prevention area in front of the mining face, a plurality of drilling sites 2 are arranged along the direction of roadway excavation, and one or more drilling holes 3 are arranged in each drilling site 2. Keep an appropriate distance between the holes, and the quantity and distance of the holes 3 holes should be determined according to the geological conditions of the coal seam 1 and the drainage rate required by the gas reserves and the effective drainage time of the holes 3;

[0024] (2) Use drilling equipment that matches the hardness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com