Fast prediction method for crossdrift and pitshaft coal uncovering burst fatalness

A prediction method and coal outburst technology, applied in measurement devices, geophysical measurements, instruments, etc., can solve the problems of delayed construction period, inability to give accuracy, and long pressure measurement time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings:

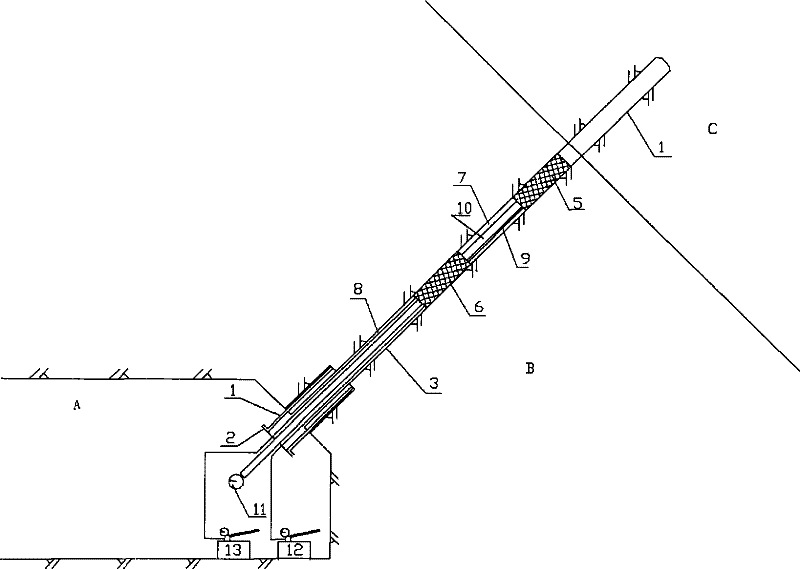

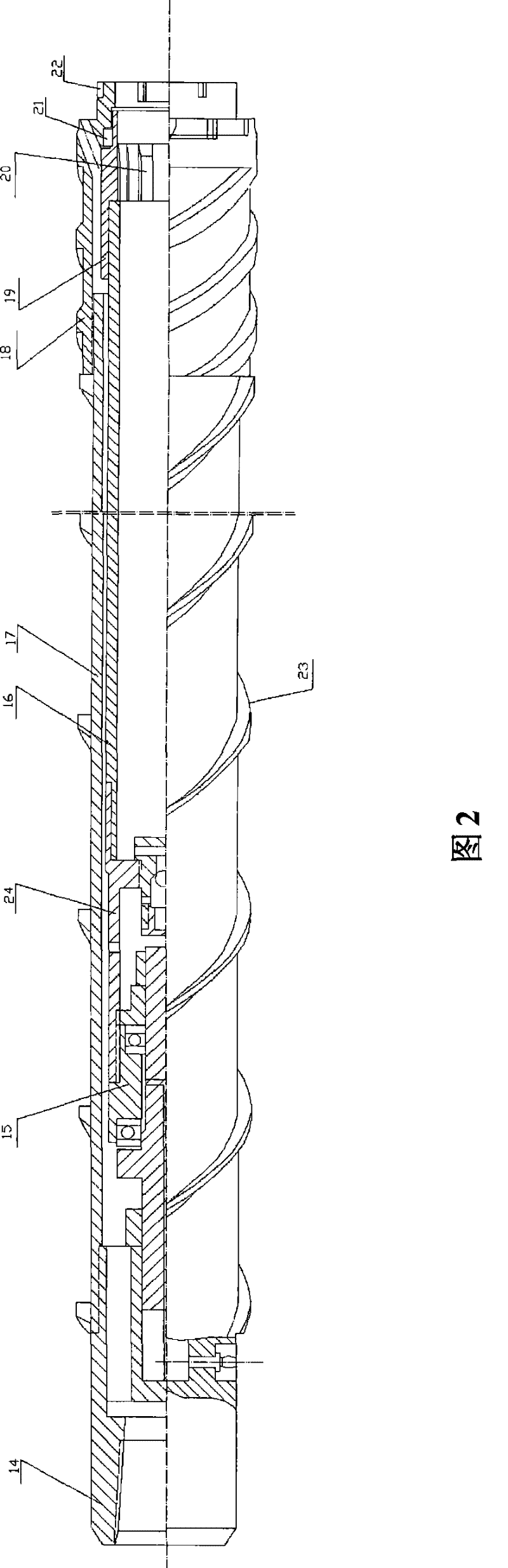

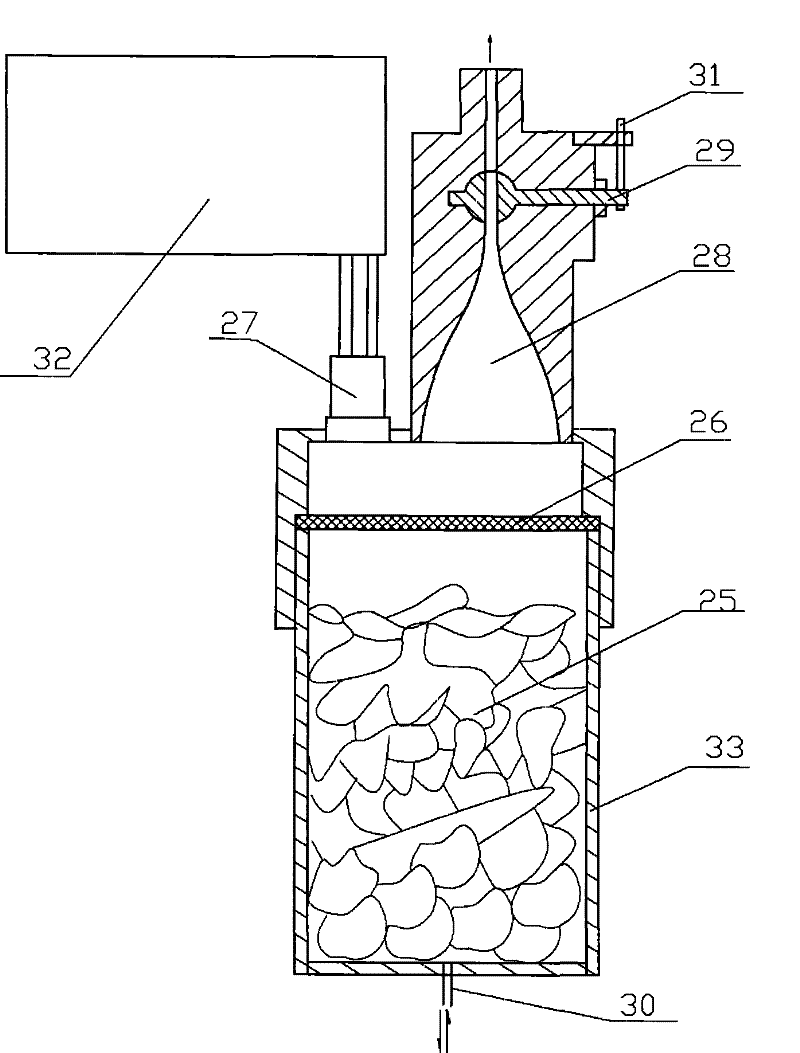

[0041] The first step is to drill a hole with a diameter of Φ about 133mm and a length of more than 2200mm into the coal seam on both sides of the roadway A or the wellbore, insert the orifice pipe 1 with the flange 2, use polyurethane or fast The dry cement is fixed, and then the cement slurry mixed with the accelerator is injected, so that the orifice pipe 1 is tightly integrated with the surrounding rock mass. The gas pressure of the coal seam can only be measured by the mucus hole sealing device in the dense rock layer; the purpose of reducing the depth of the drill bit into the coal and adopting the rapid sealing process is to reduce the coal mass around the coal hole section before sealing the hole. The amount of gas released to speed up the measurement process of gas pressure.

[0042] The second step is to drill the drill hole to a position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com