Deep-hole loosening hydraulic pressure-relief integrated blasting method and device

A deep-hole, hydraulic technology, applied in blasting, earth-moving drilling, discharging machinery, etc., can solve the problems of loose rock, difficult to put into deep holes, weakening blasting effect, etc., to achieve high operating efficiency, improve plasticity, and improve mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

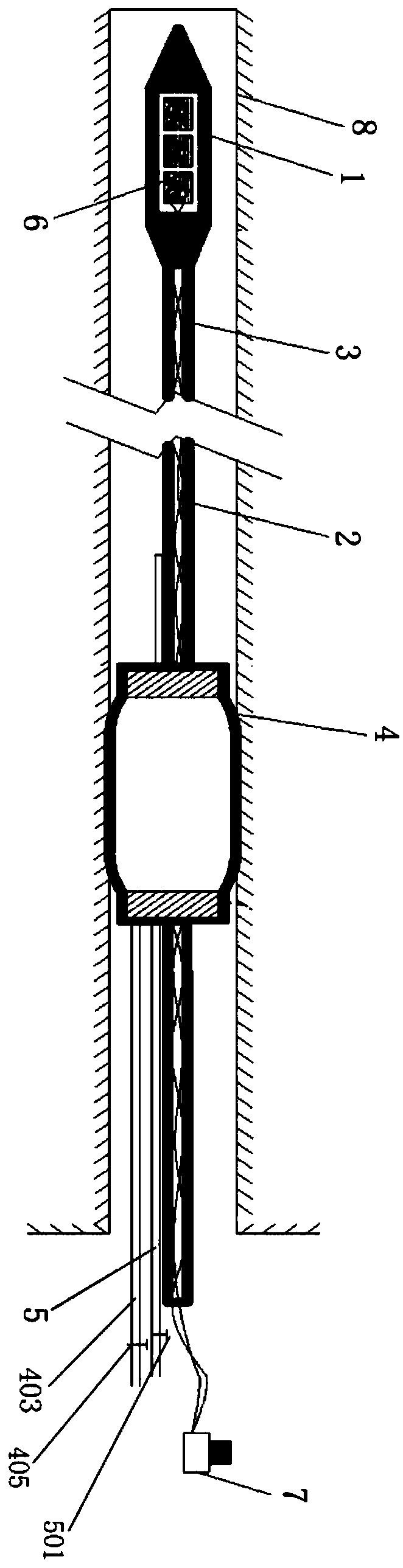

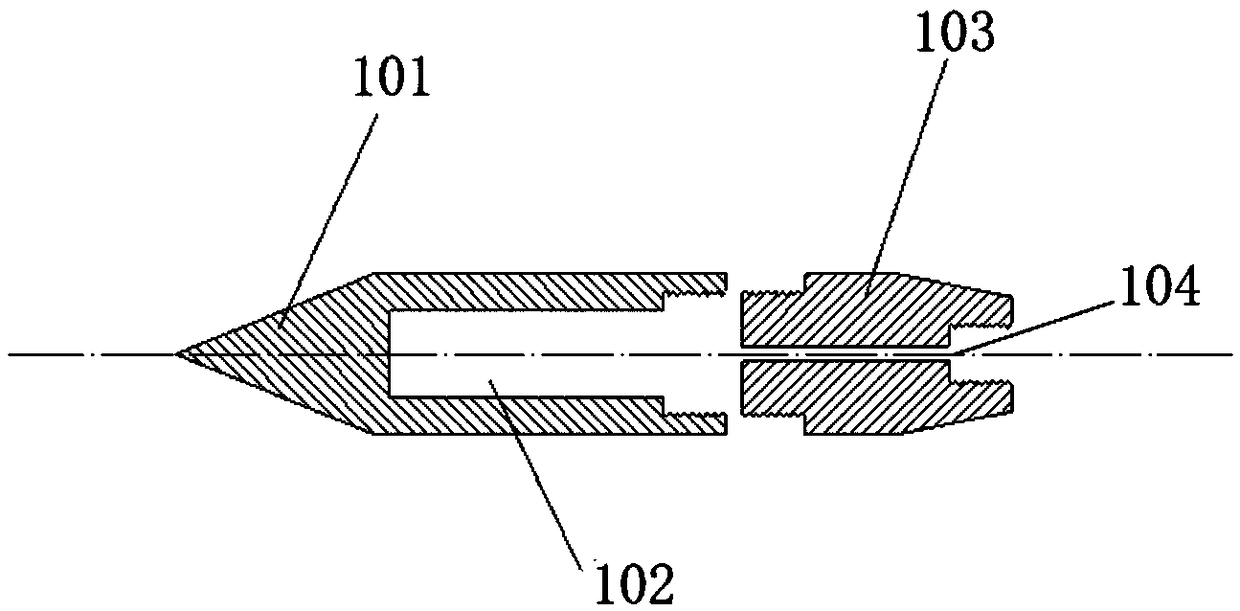

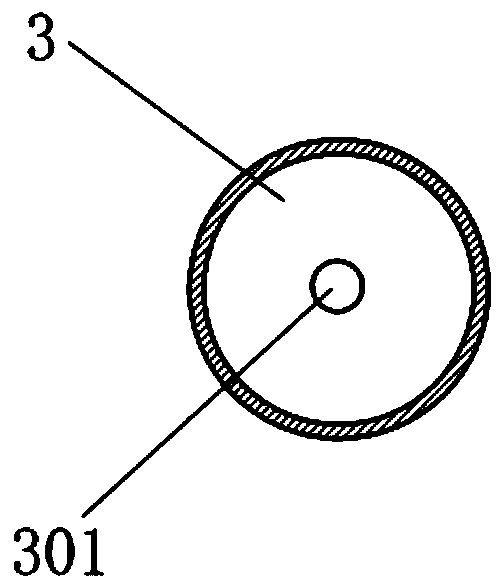

[0027] Such as figure 1 As shown, a deep hole loosening hydraulic pressure relief integrated blasting device includes a blasting cylinder 1, a blasting line 2, a drug delivery tube 3, a capsule hole sealing device 4 and a drilling water injection tube 5. Such as figure 2 As shown, the front section 101 of the blasting cylinder is a solid cone, and the apex angle of the solid cone is 25°-45°. According to the geological conditions of the coal seam, the apex angle of the solid cone is preferably 30°. The middle section 102 of the blasting barrel is hollow, and explosives 6 are built into the middle section 102 of the blasting barrel. The end of the inner wall of the middle section 102 of the blasting barrel has an internal thread, and the front end of the outer wall of the final section 103 of the blasting barrel has an external thread matching the internal thread. The solid body can prevent the leakage of blasting energy during blasting. The front end of the medicine deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com