Liquid nitrogen freezing-type rock cross-cut coal uncovering method

A technology of unearthing coal and liquid nitrogen in Shimen, which is applied in earthwork drilling, ground mining, gas discharge, etc., can solve the problems of difficult diffusion of grouting materials and limited reinforcement range, and achieve high strength of coal and rock, reduce the risk of outburst, The effect of freezing fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

[0026] A kind of liquid nitrogen freezing type Shihmen uncovering coal method of the present invention comprises the following steps:

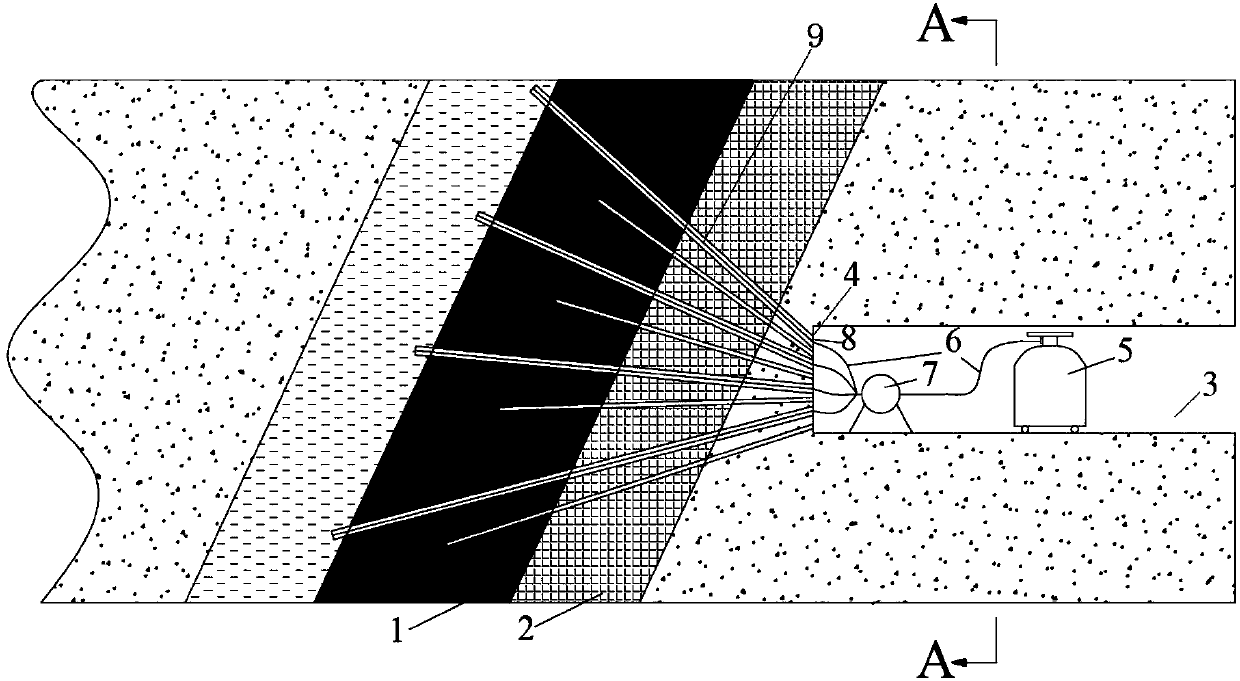

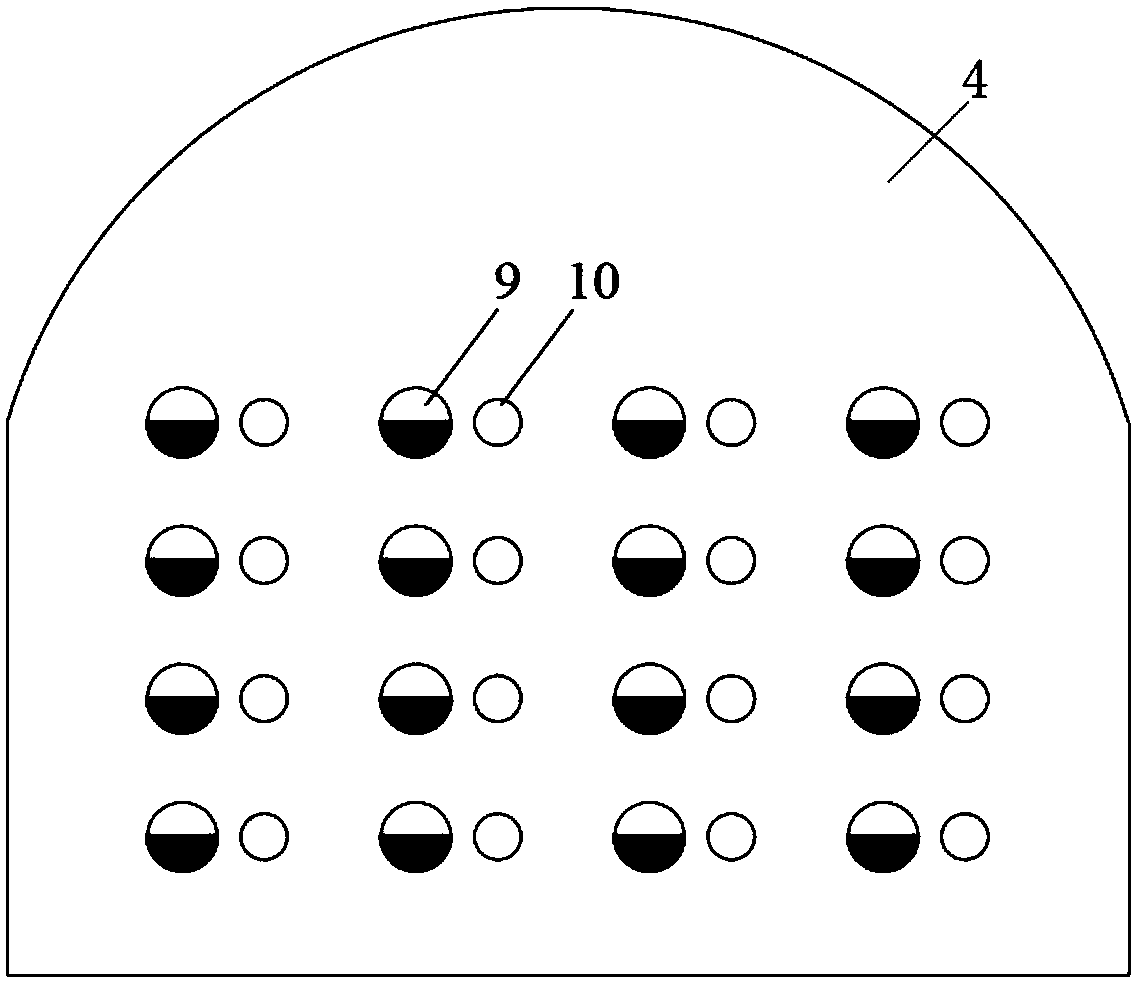

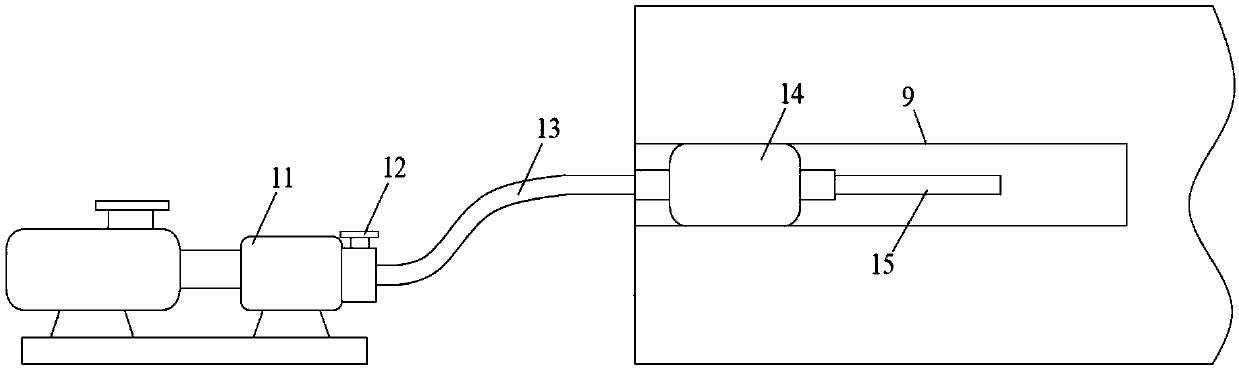

[0027] a. If Figures 1 to 3 As shown, rock roadway excavation construction is carried out in the direction of coal seam 1. When the coal mining face 4 is close to the safe rock pillar 2, a number of frozen drilling holes 9 are constructed on the coal mining face 4, and the freezing drilling holes 9 pass through the safe rock pillar 2 in turn. and the coal seam 1, the frozen boreholes 9 are arranged in a rectangular array on the coal uncovering face 4, and the distance between two adjacent frozen boreholes 9 on the coal uncovering face 4 is 1m, and each frozen borehole 9 is arranged along the The drilling direction gradually spreads to the surroundings, the water injection pipe 15 is arranged in the frozen borehole 9, and the frozen b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com