Comprehensive anti-burst construction method for rock cross-cut outburst coal seams

A construction method and a technology of outburst coal seams, which are applied in earthwork drilling, gas discharge, safety devices, etc., can solve problems such as outburst and undiscovered coal and gas, and achieve safety assurance, good advance support effect, and improved safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

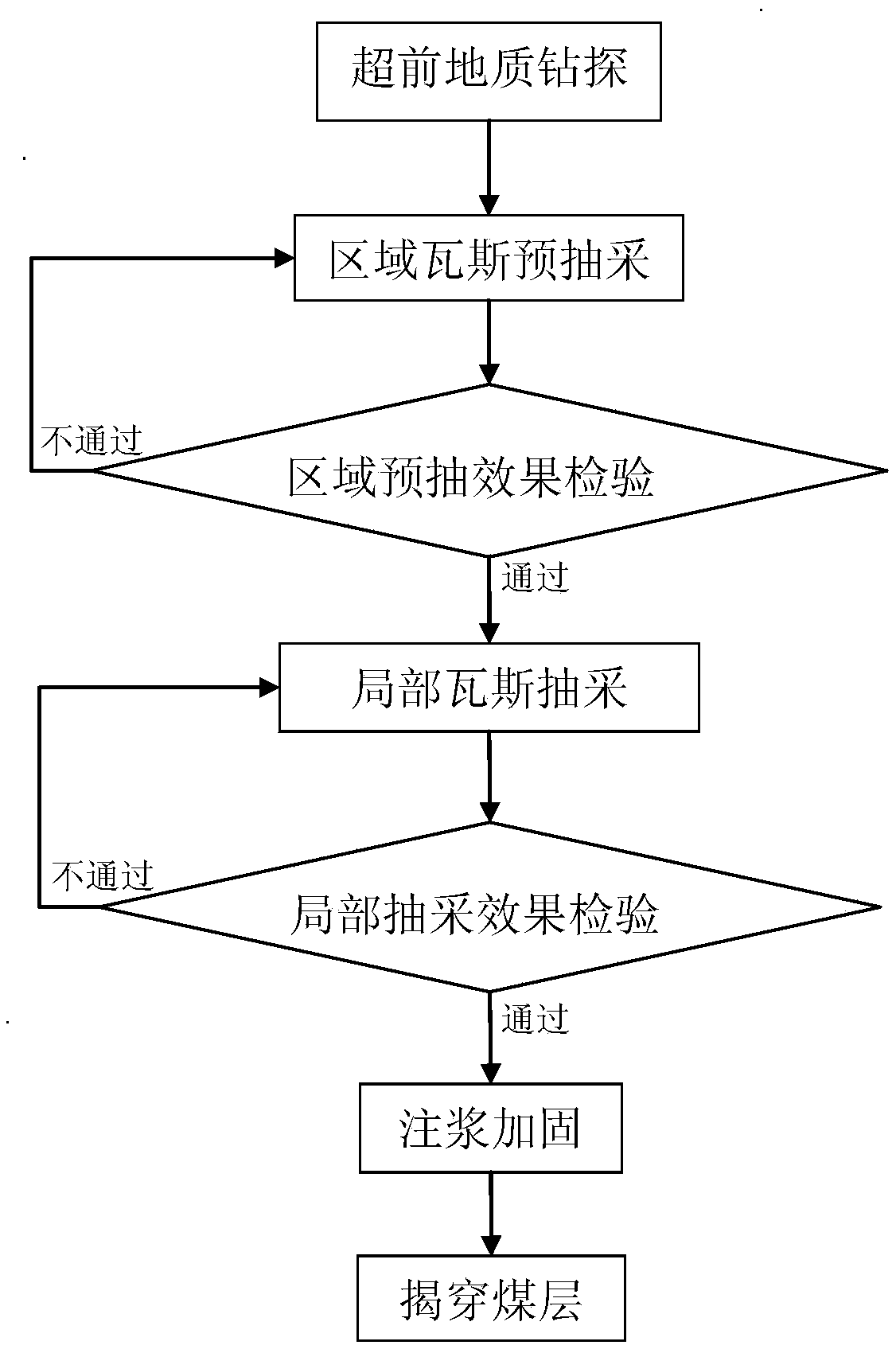

[0058] figure 1 As shown, a comprehensive outburst prevention construction method for exposing outburst coal seams in Shimen, including advanced geological drilling, regional gas pre-drainage, regional pre-drainage effect inspection, local gas drainage, local drainage effect inspection, grouting reinforcement and exposing coal seams .

[0059] The implementation process of the present invention is illustrated below in conjunction with accompanying drawing:

[0060] The project adopts a comprehensive outburst prevention construction method of exposing the outburst coal seam at the Shimen. The specific construction steps are as follows:

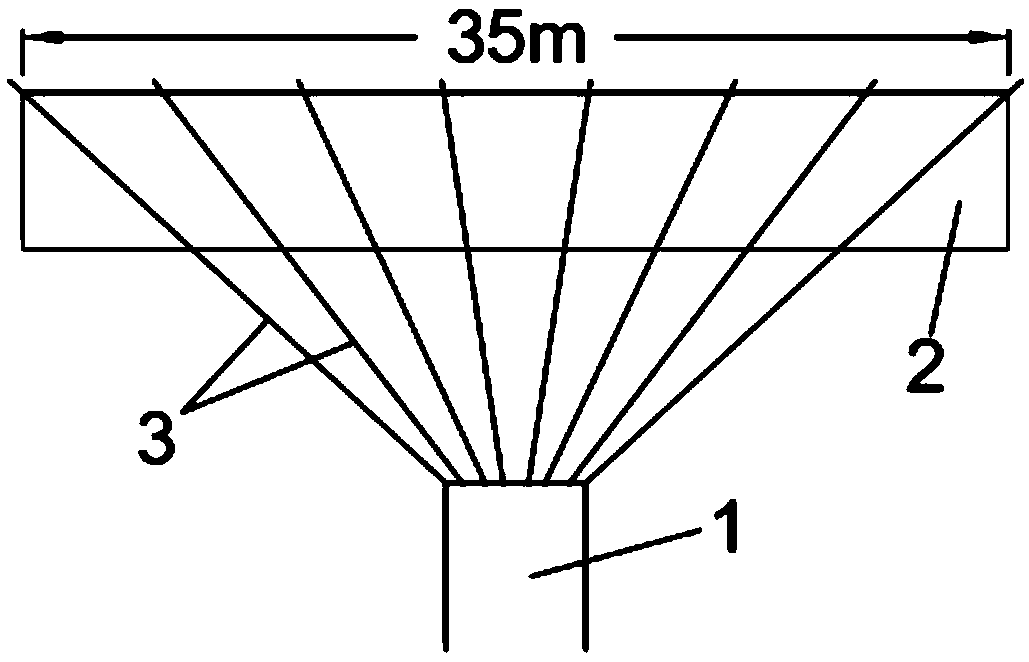

[0061] (1) Advanced geological drilling

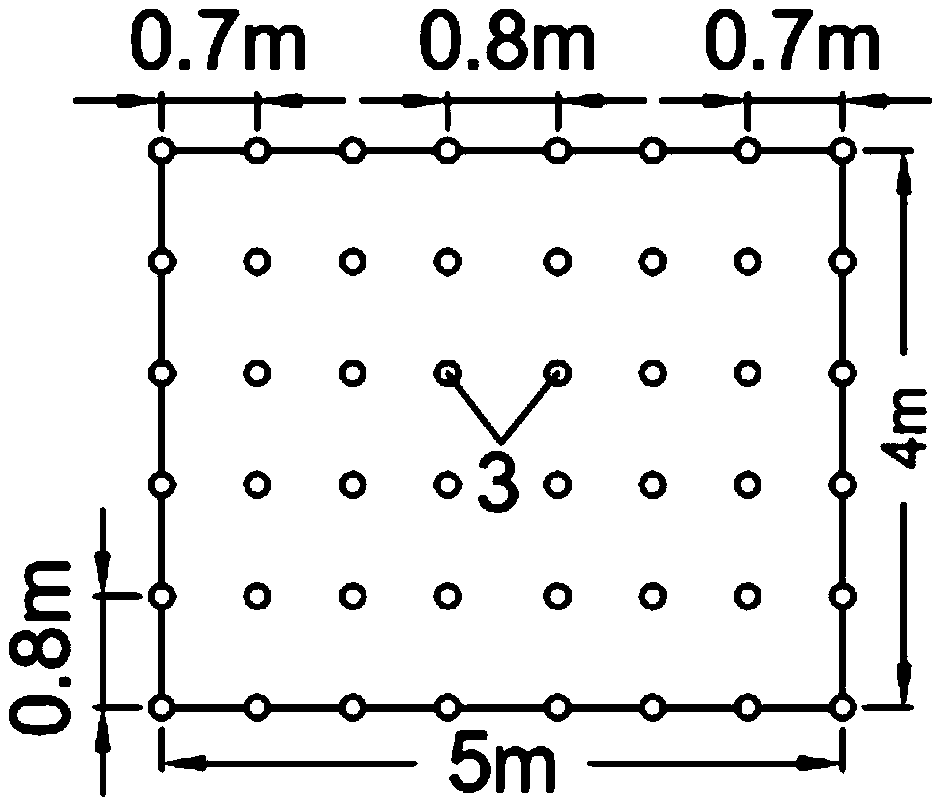

[0062] When the vertical distance between Shimen 1 head-on and coal seam 2 is 15m, stop the excavation, and use ZYJ-420 / 200 type frame-pillar hydraulic rotary drilling rig to construct advanced geological drilling holes on the head-on section of Shimen (1), and the number of advanced geological drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com