Outburst prevention technique for multiple heading in coal mine

A process and outburst prevention technology, which is applied in the field of outburst prevention technology for multi-lane excavation in coal mines, can solve the problems of single outburst prevention measures and low efficiency, and achieve the effects of saving time for local outburst prevention measures and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

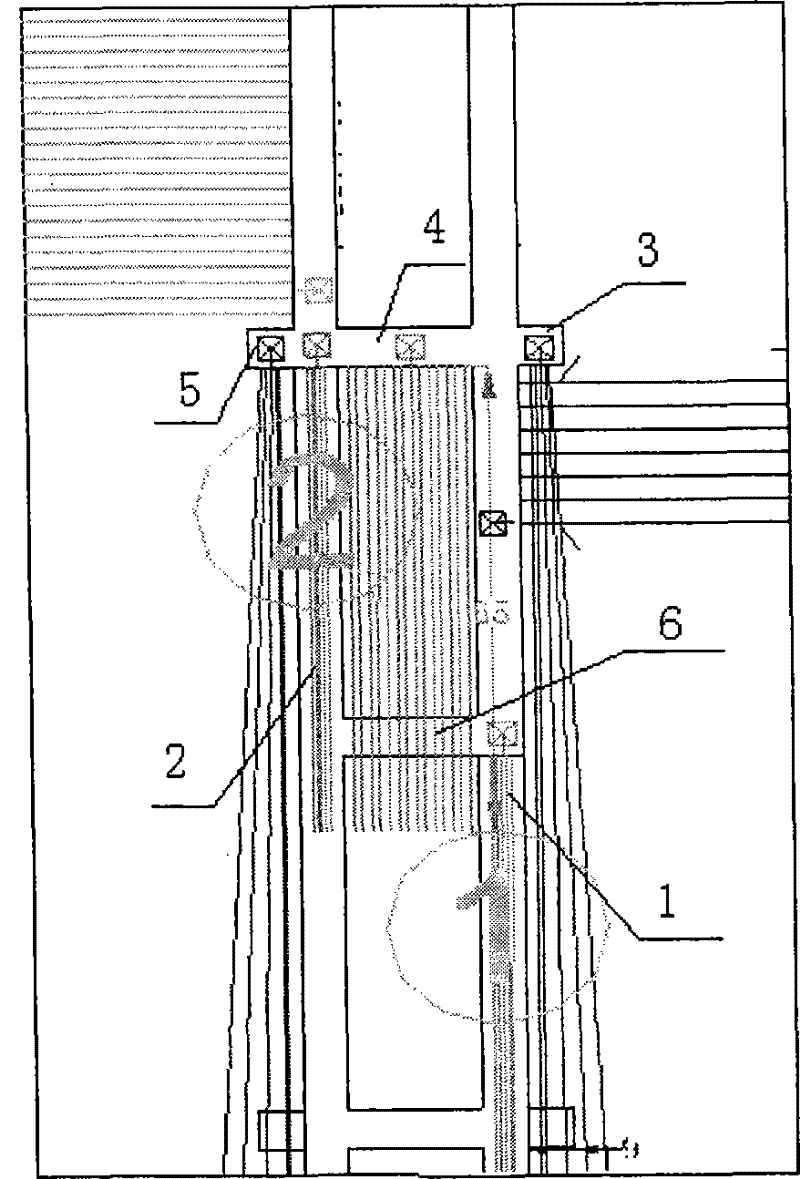

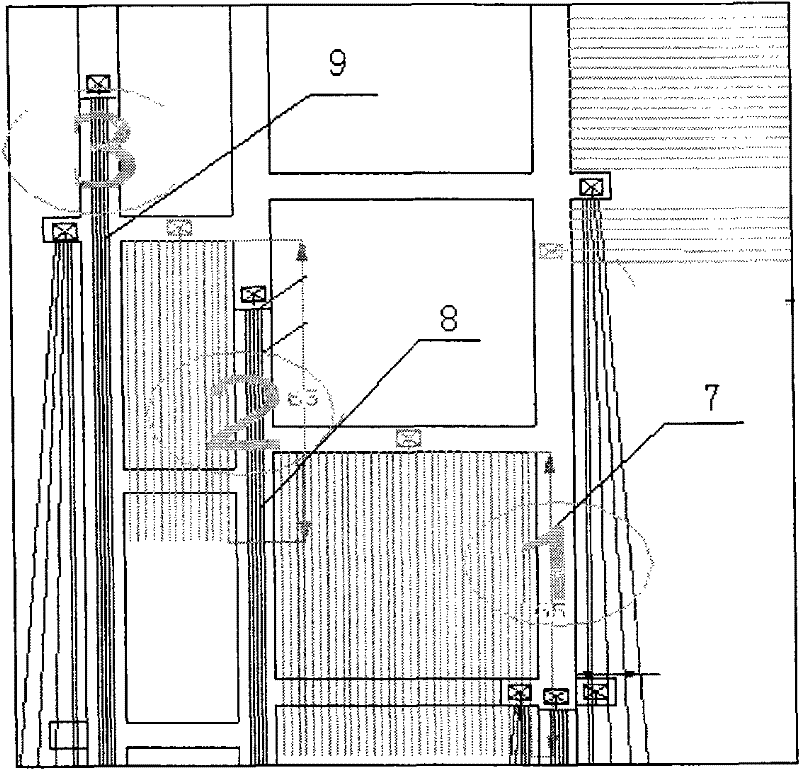

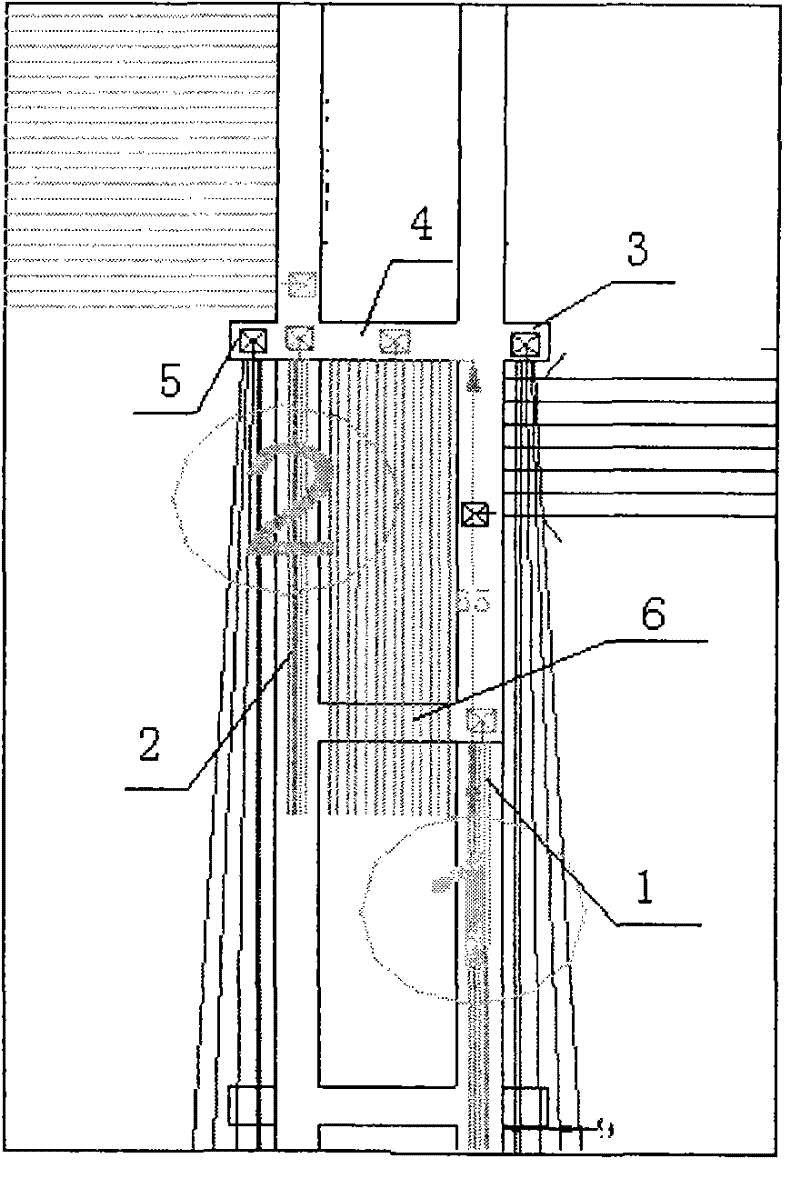

Image

Examples

Embodiment Construction

[0008] First introduce the specific implementation of the anti-burst process at this stage

[0009] (1) Prediction of outburst hazards in coal roadway excavation face

[0010] Using the drill cuttings index method to predict the outburst risk of coal roadway excavation face, follow the steps below:

[0011] (1) Three predictive boreholes with a diameter of 42mm and a depth of 10m are horizontally arranged in the soft layer of the working face section, one borehole is located in the middle of the working face, parallel to the direction of roadway excavation, and the other two boreholes are arranged on the side of the roadway , the opening is 0.5m away from the side of the roadway, the final hole is 3m outside the outline of the roadway, and the angle between the roadway and the roadway is 21 degrees. When there is no soft delamination, the drilling is arranged in the center of the working face.

[0012] (2) For every 1m of drilling, collect and measure the amount of cuttings (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com