Electric pulse hydraulic fracturing integration device

A hydraulic fracturing and electric pulse technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve problems such as inability to loosen, and achieve the effects of improving plasticity, improving mechanical properties, and reducing outburst risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

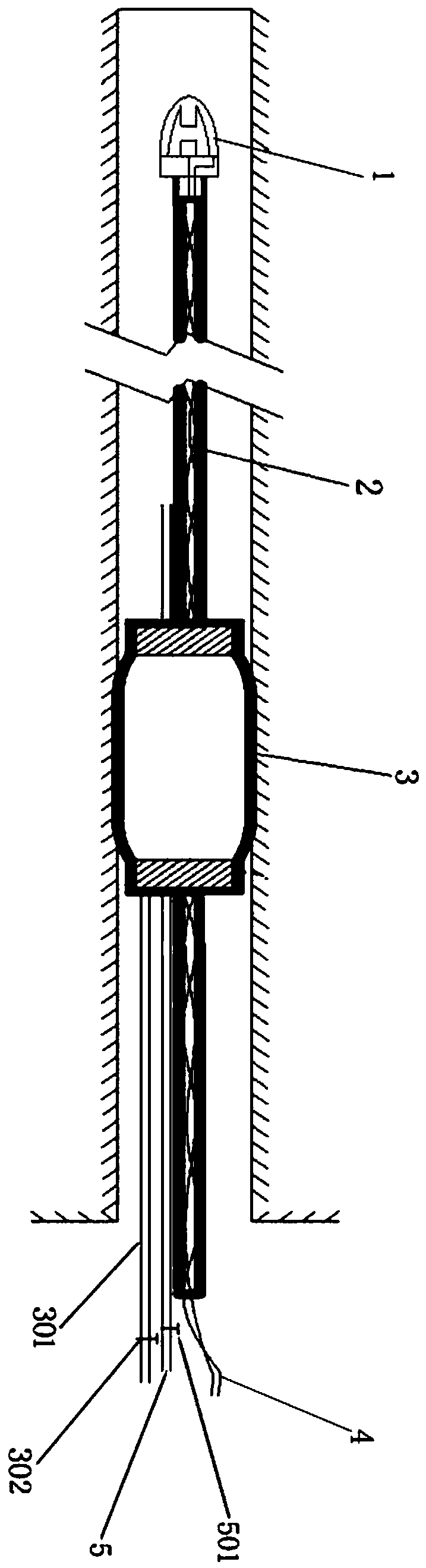

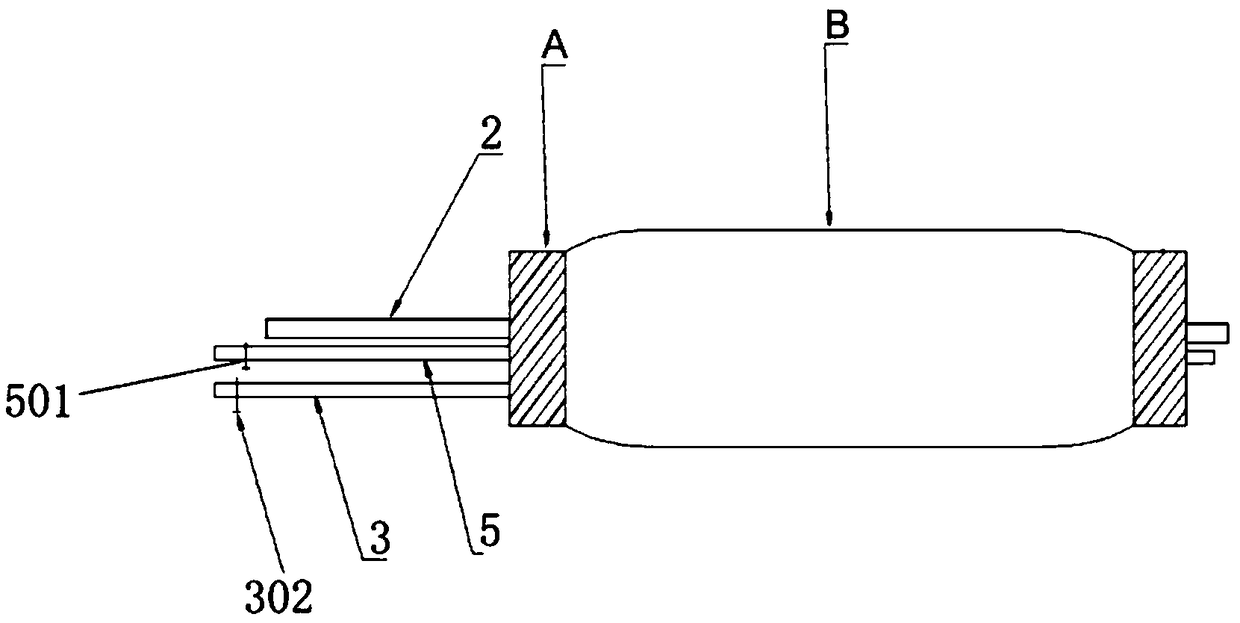

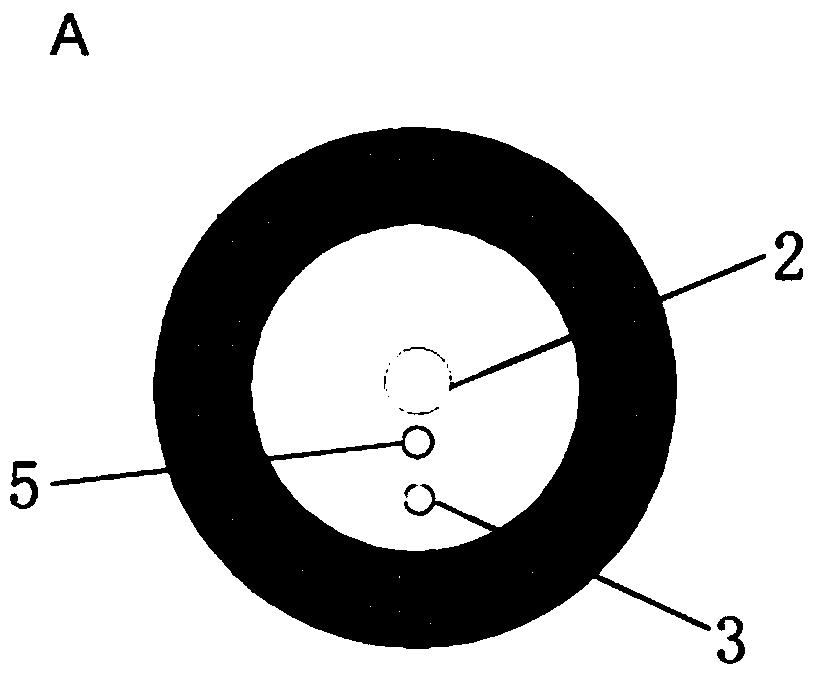

[0022] Such as figure 1 As shown, an electric pulse hydraulic fracturing integrated device includes a discharge electrode 1, a high-voltage cable 4, a line pipe 2, a high-voltage energy storage capacitor, a capsule hole sealer 3, a drilling water injection pipe 5 and a capsule water injection pipe 301. The discharge electrode 1 is fixed at the front end of the line tube 2, one end of the high-voltage cable 4 is connected to the discharge electrode 1, and the other end of the high-voltage cable 4 passes through the line tube 2 and is connected to the high-voltage energy storage capacitor. The capacitance of the high-voltage energy storage capacitor is 20 ~40μF, the capsule sealer 3 is connected to the line tube 2 in series.

[0023] Such as figure 2 , 3 As shown in and 4, the front end of the capsule water injection pipe 301 extends into the capsule sealer 3, and the front end of the drilling water injection pipe 5 passes through the capsule sealer 3. The first valve 302 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com