Preparation of waste potato residue/palygorskite composite adsorbent and application of adsorbent in treatment of potato starch processing wastewater

A technology of potato starch and composite adsorption, applied in the direction of adsorption water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of high construction cost and treatment cost, achieve good promotion value, reduce cost, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

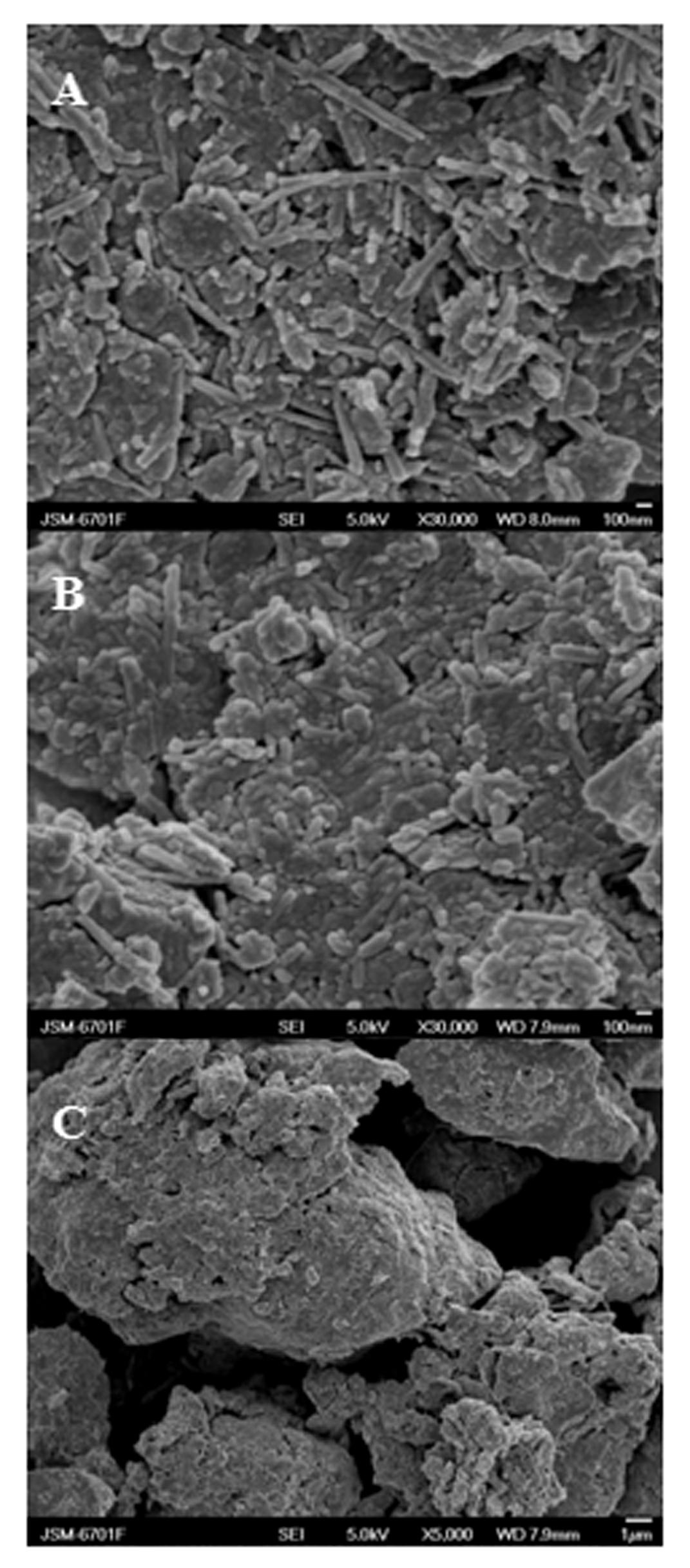

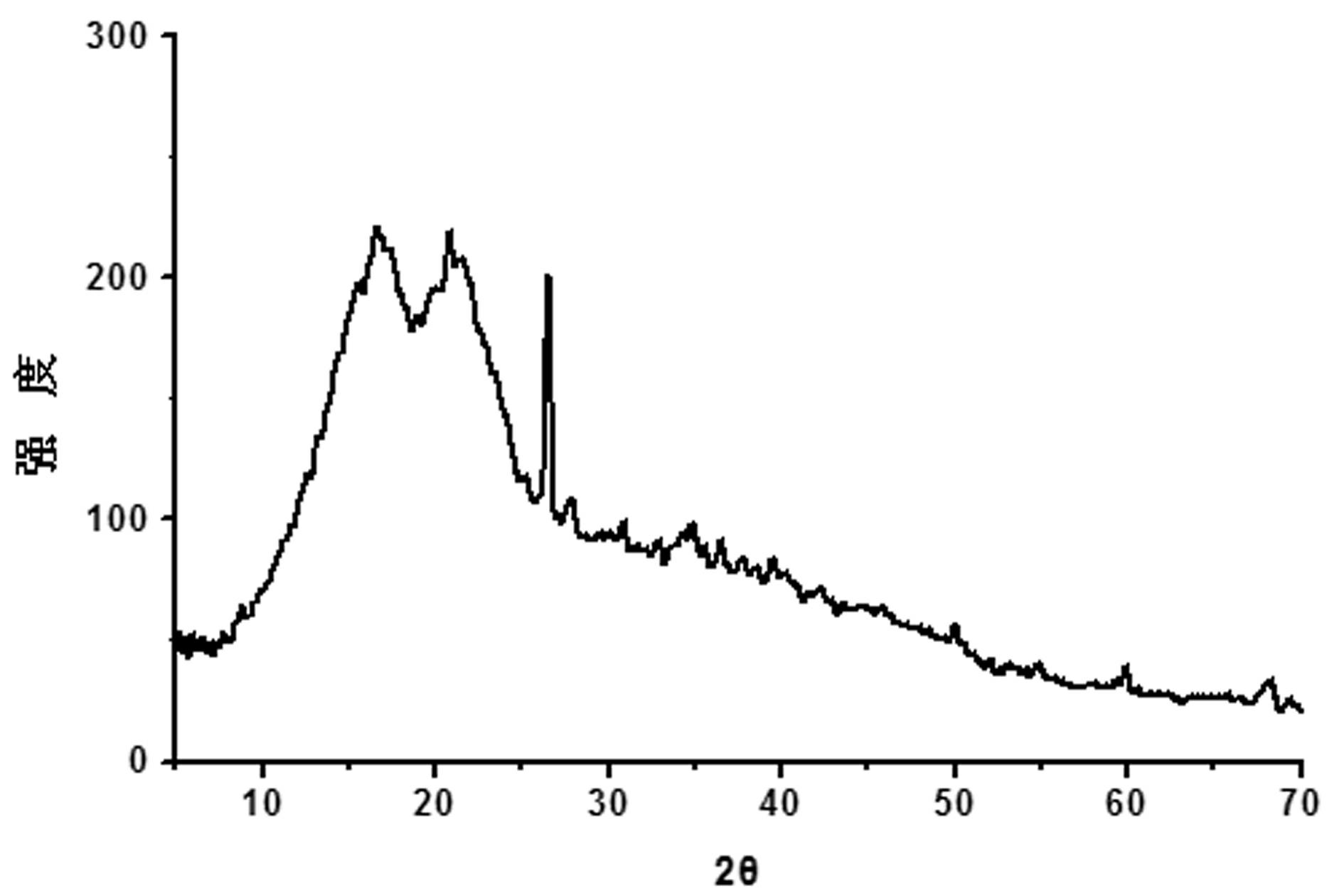

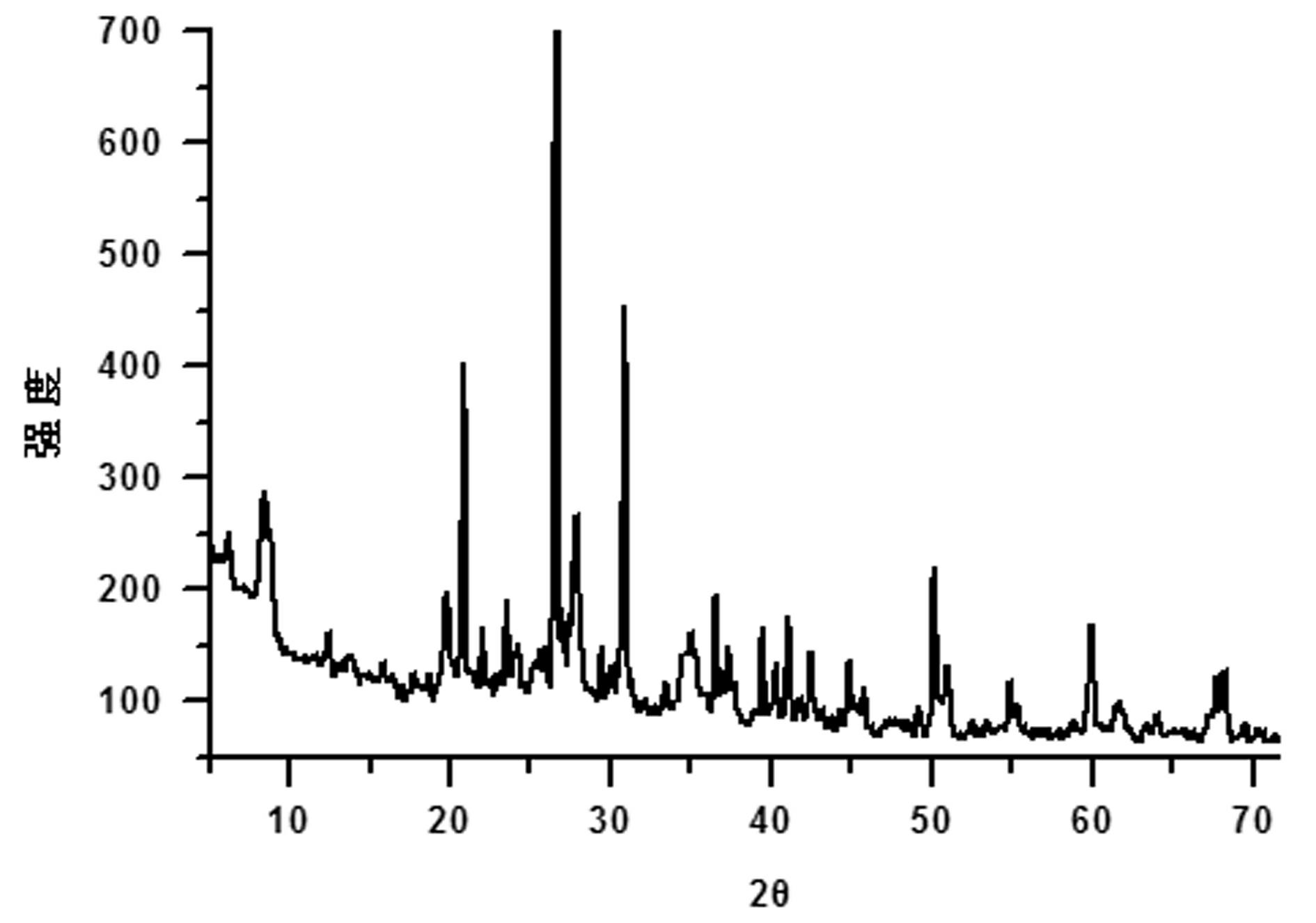

[0039] 1. Preparation of potato waste residue / palygorskite composite adsorbent

[0040] (1) Select Linze palygorskite raw ore, dry it and crush it, pass through a 200-mesh sieve to become palygorskite clay powder for later use;

[0041] (2) Add palygorskite clay powder and fresh potato residue (taken from a company in Huining, Gansu) to distilled water at a mass ratio of 1:0.5, and stir to form a uniform mass concentration. 5% slurry, and ultrasonically dispersed for 30 minutes;

[0042] (3) Transfer the slurry to the hydrothermal reaction kettle. The filling volume of the hydrothermal reaction kettle is kept at 60%. The reaction temperature is 120°C and the carbonization time is 48h. After the carbonization reaction is completed, the product is naturally cooled and washed. Dried at 70°C and crushed to obtain a potato residue / palygorskite composite adsorbent.

[0043] 2. Treatment of potato starch processing wastewater

[0044] Source of wastewater: Wastewater from potato s...

Embodiment 2

[0049] 1. Preparation of potato waste residue / palygorskite composite adsorbent

[0050] (1) Select Linze palygorskite raw ore, dry it and crush it, pass through a 200-mesh sieve to become palygorskite clay powder for later use;

[0051] (2) Add palygorskite clay powder and fresh potato residue (taken from a company in Huining, Gansu) to distilled water at a mass ratio of 1:1, and stir to form a uniform mass concentration. 10% slurry, and ultrasonically dispersed for 30 minutes;

[0052] (3) Transfer the slurry to the hydrothermal reaction kettle. The filling volume of the hydrothermal reaction kettle is kept at 60%, the reaction temperature is 140°C and the carbonization time is 40h. After the carbonization reaction is completed, the product is naturally cooled and washed. Dried at 70°C and crushed to obtain a potato residue / palygorskite composite adsorbent.

[0053] 2. Treatment of potato starch processing wastewater

[0054] Source of wastewater: Wastewater from potato st...

Embodiment 3

[0059] 1. Preparation of potato waste residue / palygorskite composite adsorbent

[0060] (1) Select Linze palygorskite raw ore, dry it and crush it, pass through a 200-mesh sieve to become palygorskite clay powder for later use;

[0061] (2) Add palygorskite clay powder and fresh potato residue (taken from a company in Huining, Gansu) to distilled water at a mass ratio of 1:2, and stir to form a uniform mass concentration. 15% slurry, and ultrasonically dispersed for 30 minutes;

[0062] (3) Transfer the slurry to the hydrothermal reaction kettle. The filling volume of the hydrothermal reaction kettle is kept at 60%, the reaction temperature is 160°C and the carbonization time is 32h. After the carbonization reaction is completed, the product is naturally cooled and washed. Dried at 70°C and crushed to obtain a potato residue / palygorskite composite adsorbent.

[0063] 2. Treatment of potato starch processing wastewater

[0064] Source of wastewater: Wastewater from potato st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com