Potato masher

A potato mash machine technology, which is applied in food preparation, application, food science, etc., can solve the problems of increasing the natural deterioration of mashed potatoes, low efficiency, and the impossibility of adapting to the needs of production scale and rhythm, and achieves simple structure and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

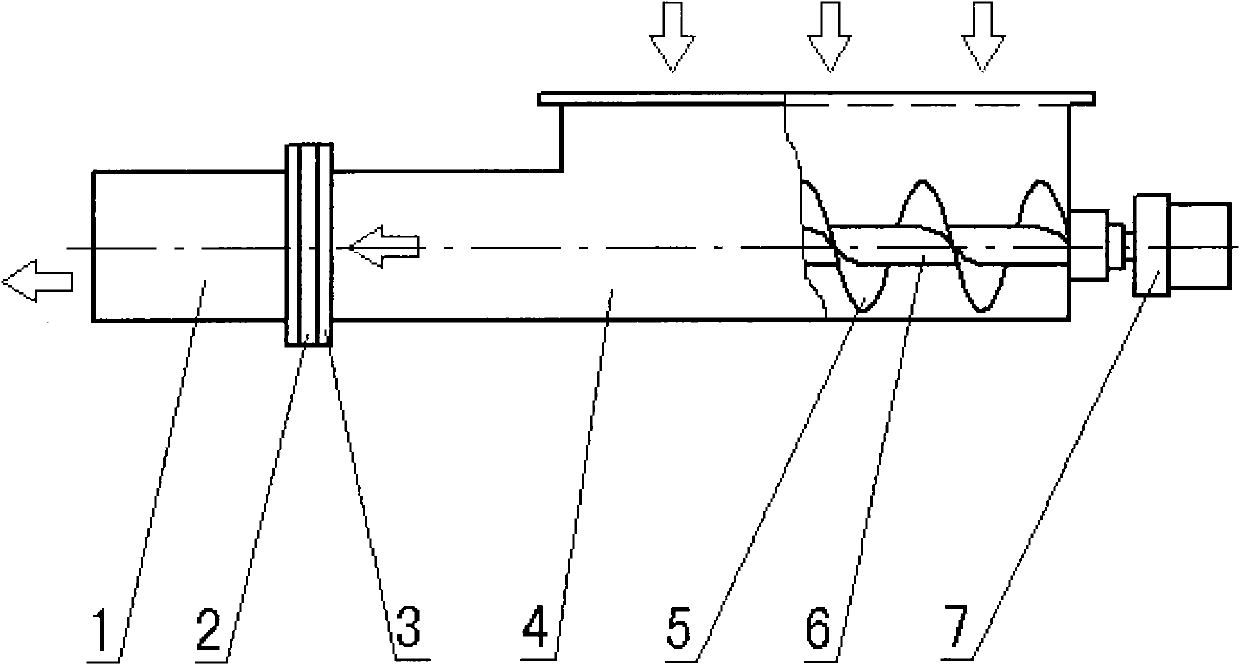

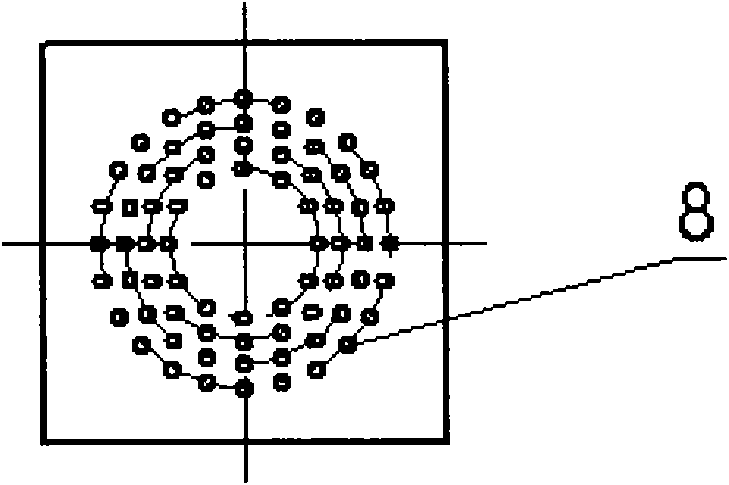

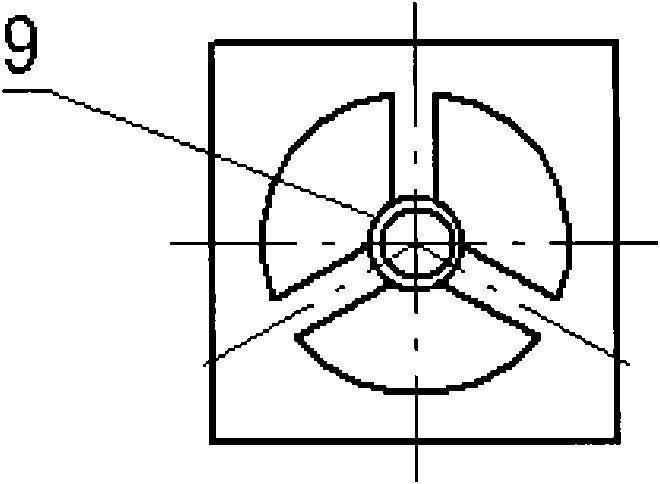

Embodiment 1

[0013] Embodiment 1 is the situation that the potato masher that the present invention implements is used on the potato whole flour industrial production line: the potato after the steaming is dropped in an orderly manner by the flange opening of the rectangular tube on the U-shaped groove of the casing (4). into the casing (4), driven by the transmission device (7), the main shaft ( 6) Rotate continuously, and drive the pusher screw (5) fixed on its outer circumference to continuously push the cooked potatoes to the mud-making plate (2), because the pusher screw (5) at the discharge end It is a variable-pitch screw, so that the extrusion strength of the cooked potatoes can be increased, and the mud-making plate (2) arranged in the rectangular socket at the junction of the casing flange (3) and the discharge cylinder flange, Increase the resistance of its backward displacement, forcing the boiled potatoes to speed up the process of disintegration and discretization into mashed...

Embodiment 2

[0014] Embodiment 2 The potato puree making machine that the present invention implements can be used on the industrial production line of making sweet potato powder, taro powder, pumpkin powder, sweet potato powder and other food raw materials. Its working principle and process are the same as those in Example 1 Identical, its result can make the intermediate product that meets quality requirement, muddy multiple food equally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com