Method for preparing high-stable sweet potato pectin emulsion

A technology of high stability and emulsion, which is applied in the field of preparation of high stability sweet potato pectin emulsion, can solve the problems of pollution, waste of resources and environment, and achieve the effect of improving the application range, wide sources and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

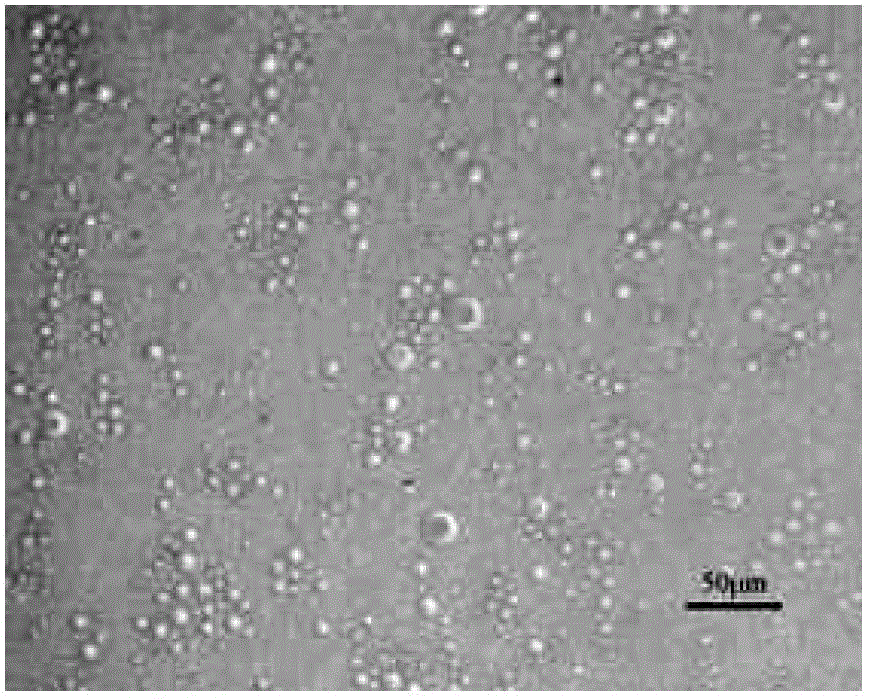

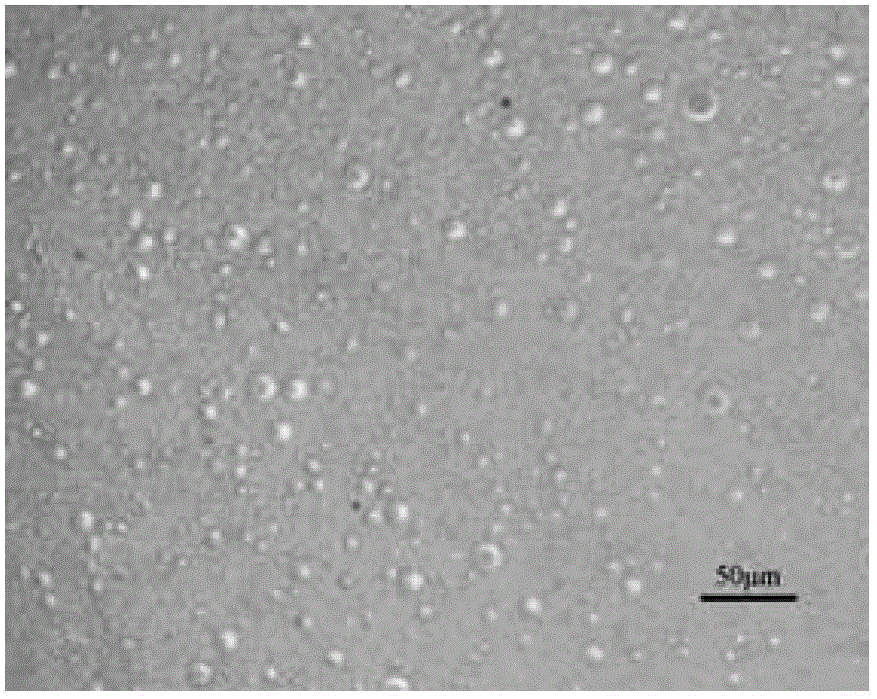

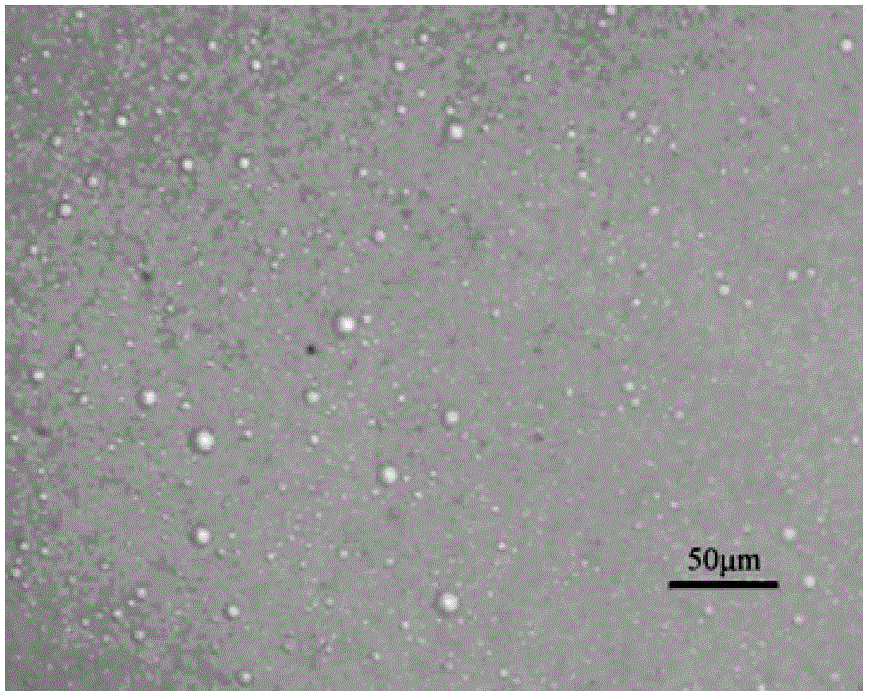

Image

Examples

Embodiment Construction

[0027] The technical process of the present invention is: pretreatment of sweet potato slag, preparation of sweet potato pectin, preparation of sweet potato pectin aqueous solution, mixing of sweet potato pectin aqueous solution and soybean oil, and homogeneous mixing to obtain highly stable sweet potato pectin emulsion.

[0028] Most preferably, the pectin is mixed with distilled water at a mass-volume ratio of 1.0%-3.0%, and the pH value is adjusted to 4.0-6.0. The pectin aqueous solution is mixed with soybean oil, the volume ratio of soybean oil in the mixture is 5%-40%, and the mixture is homogenized at 20000rpm for 1min. The optimum volume ratio of soybean oil in the mixture is 10%-30%.

[0029] The present invention is described in detail below with specific examples.

[0030] Example 1. (1) Pretreatment of sweet potato dregs for starch production: dry sweet potato dregs until the moisture content is less than 5%, pass through a 100-mesh sieve after crushing, suspend ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com