Method for recycling potato residue and waste water in production process of potato starch

A potato starch and production process technology, applied in the direction of separation methods, other chemical processes, chemical instruments and methods, etc., can solve the problems affecting the surrounding environment and the sustainable development of the potato starch processing industry, high organic matter content and COD value, equipment High operating costs and other issues, to achieve the effects of low equipment and operating costs, reduced organic matter content and COD value, and improved dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

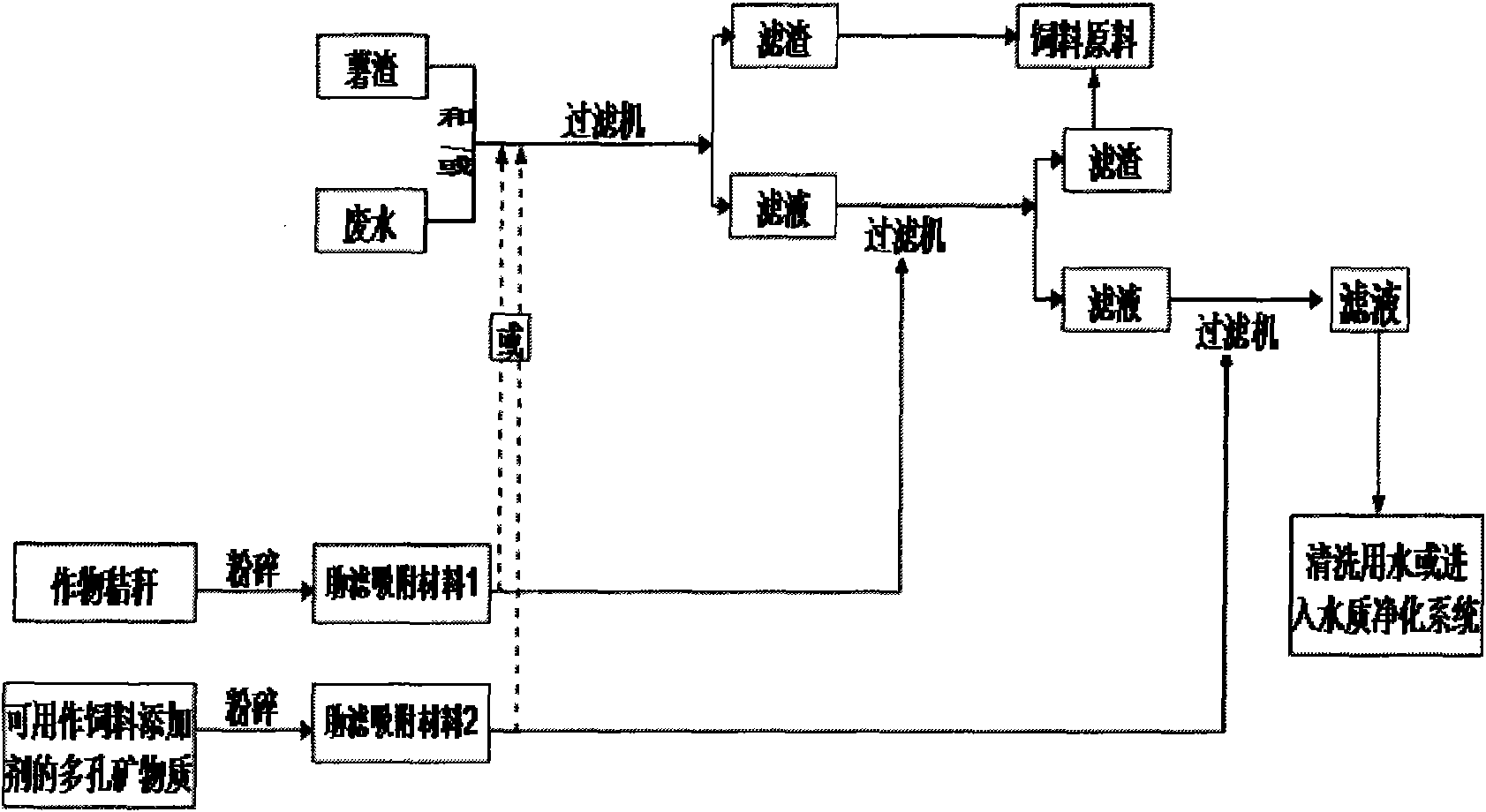

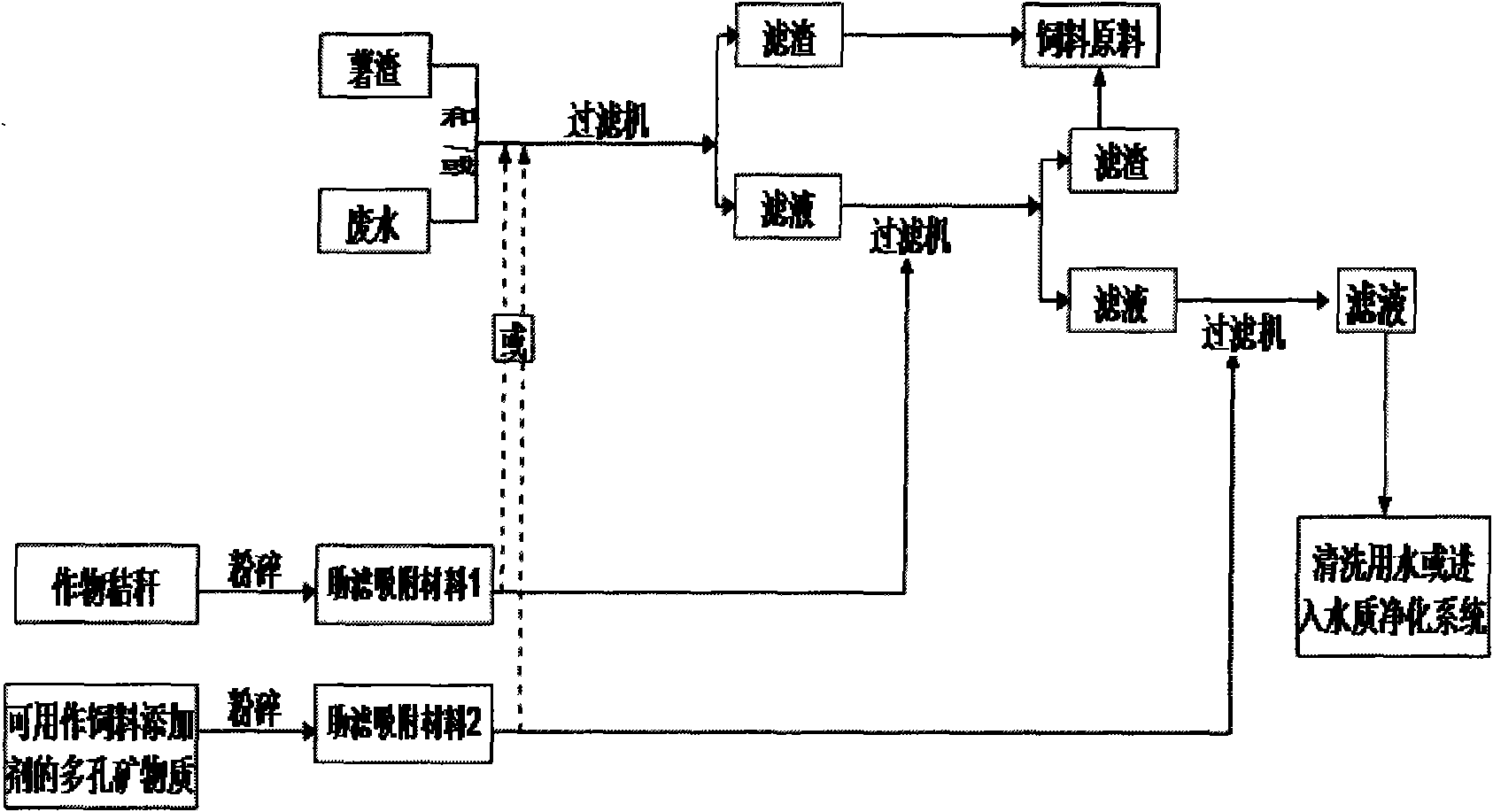

[0027] Such as figure 1 The method for recycling potato residue and waste water in the production process of potato starch of the present invention includes the following steps:

[0028] (1) Preparation of filter aid adsorption materials 1 and 2

[0029] Prepare the corn stalks into particles with a size of 1-30 mm through a physical crushing method, which are used as the filter-aid adsorption material 1;

[0030] The attapulgite is prepared into particles with a size of 0.1-5 mm through a physical crushing method, which is used as the filter-aid adsorption material 2;

[0031] (2) Mix the wet potato residue after potato starch processing with wastewater (potato residue: wastewater = 1:0.1 (w / w)), add the filter-aid adsorption material 1 to 0.5% of the weight of the mixture, mix and stir for 10 minutes, then enter The screw extrusion filter continuously filters to obtain the filter residue and filtrate. The obtained filtrate is continuously filtered through a screw extrusion filter ...

Embodiment 2

[0033] (1) Preparation of filter aid adsorption materials 1 and 2

[0034] The Codonopsis pilosula stalk is physically crushed into particles with a size of 1-30 mm, which are used as the filter-aid adsorption material 1;

[0035] The attapulgite is prepared into particles with a size of 0.1-5 mm through a physical crushing method, which is used as the filter-aid adsorption material 2;

[0036] (2) In the wet potato residue of potato starch processing, 2% of the weight of the wet potato residue is added to the filter-aid adsorption material 2 and mixed and stirred for 15 minutes, then enter the filter for continuous filtration to obtain filter residue and filtrate. The obtained filtrate is then continuously filtered through the filter with the filter-aid adsorption material 1, the material layer is 35 cm thick, and then the filter residue and the filtrate are generated. The filter residue obtained in the above two steps can be directly dried into feed material or added with bacteria...

Embodiment 3

[0038] (1) Preparation of filter aid adsorption materials 1 and 2

[0039] Prepare the wheat straw into particles with a size of 1-30 mm through a physical crushing method, which is used as the filter-aid adsorption material 1;

[0040] Prepare diatomaceous earth into particles with a size of 0.1-5 mm through a physical pulverization method, which is used as a filter-aid adsorption material 2;

[0041] (2) In the potato starch processing wastewater, 8% of the weight of the wastewater is added to the filter-aid adsorption material 1 and mixed and stirred for 20 minutes, then enter the screw extrusion filter for intermittent filtration to obtain filter residue and filtrate. The obtained filtrate is then intermittently filtered through a screw extrusion filter with the filter-aid adsorption material 1, the material layer is 50 cm thick, and then filter residue and filtrate are generated. The filter residue obtained in the above two steps can be directly dried into feed material or ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com