Novel method for extracting pectin from sweet potato dregs

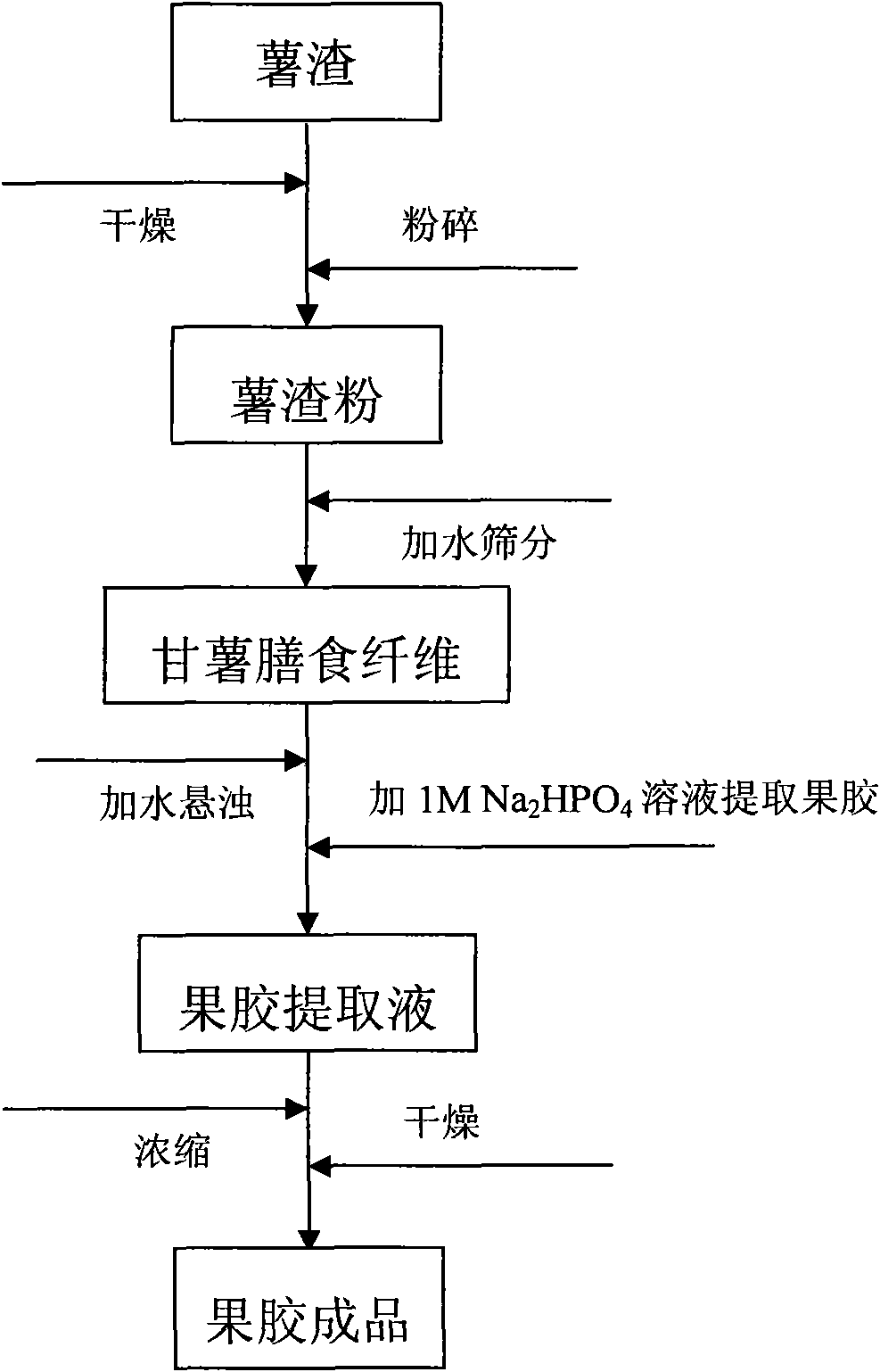

A technology of sweet potato dregs and pectin, which is applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, food preparation, etc., can solve the problems affecting the quality and purity of pectin products, and high cost, so as to improve comprehensive economic benefits and low cost , The effect of easy factory production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, the process optimization of extracting sweet potato pectin

[0049] 1. Sweet potato residue crushing and particle size determination

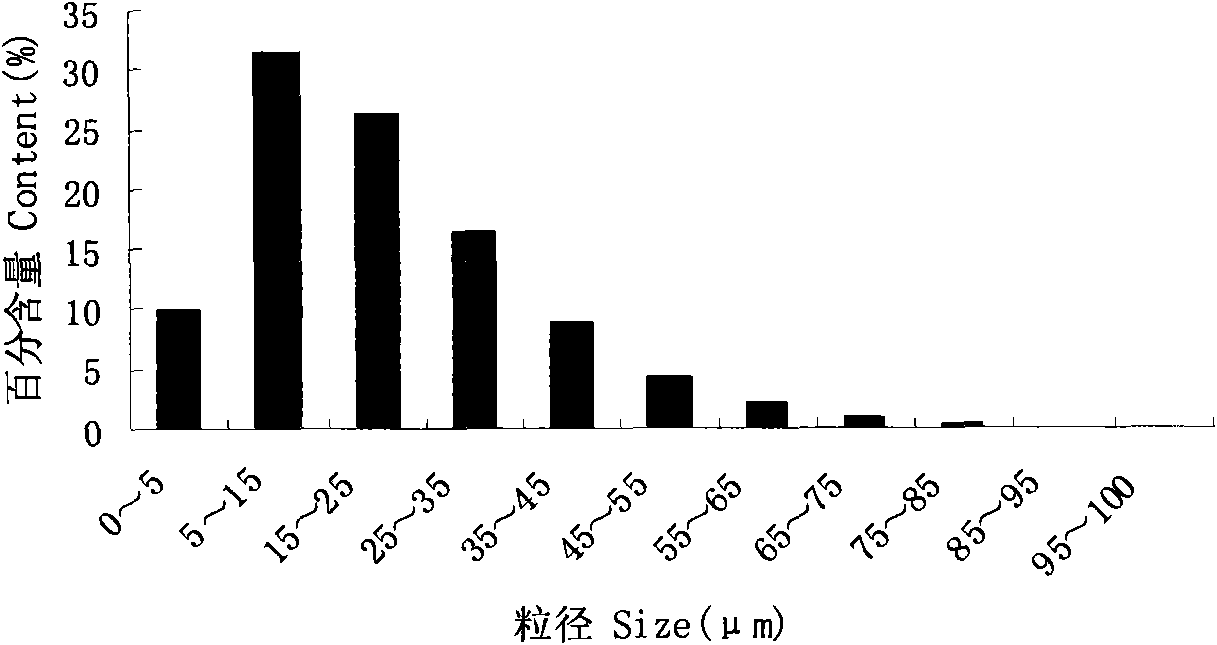

[0050] A laser particle size analyzer (BT-9300H) was used to measure the particle size distribution of sweet potato starch to determine the sieve aperture when removing starch. The results show that the particle size of sweet potato starch is mainly distributed in 0-35μm (see figure 2 ).

[0051] Weigh 30g of sweet potato dregs (the variety is Xu 55-2), pulverize with a universal grinder (FW100 type), observe the particle size distribution range of sweet potato dregs at different crushing times (sweet potato dregs particle size is 0-150 μm, and 35-150 μm particles account for the total 50-70% is the best crushing time), and finally the best crushing time is determined to be 20s.

[0052] 2. Separation of sweet potato dietary fiber from sweet potato residue

[0053] The crushed sweet potato residue is first passed through...

Embodiment 2

[0068] Embodiment 2, sweet potato pectin extraction rate and purity detection

[0069] 1. Sweet potato residue crushing and particle size determination

[0070] Weigh 30g of dried sweet potato dregs (type Xu 55-2), pulverize them with a universal grinder (FW100 type) for 20s, and measure the particle size distribution range of sweet potato dregs at different crushing times. 150μm particles accounted for 50-70% of the total.

[0071] 2. Separation of sweet potato dietary fiber from sweet potato residue

[0072] Mix 15g of sweet potato residue obtained in step 1) with water at a mass ratio of 1:60 to form a suspension, adjust the pH value of the solution to 5.0, sieve for 20min at a reciprocating vibration frequency of 3.75Hz, and remove starch to obtain 3.66g of meal Fiber (this number is the following DF1) (see Figure 4 ), of which the total dietary fiber content is 2.97g (this number is DF2 below)

[0073] The calculation method of dietary fiber extraction rate and purit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com