Equipment for producing round steamed bread

A production equipment and round steamed bun technology, which is applied in the field of round steamed bun production equipment and staple food steamed bun production machinery, which can solve the problems of poor surface brightness, large dough damage, and high labor intensity, and achieve dense dough rolls, large and small appearance Uniform, brightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

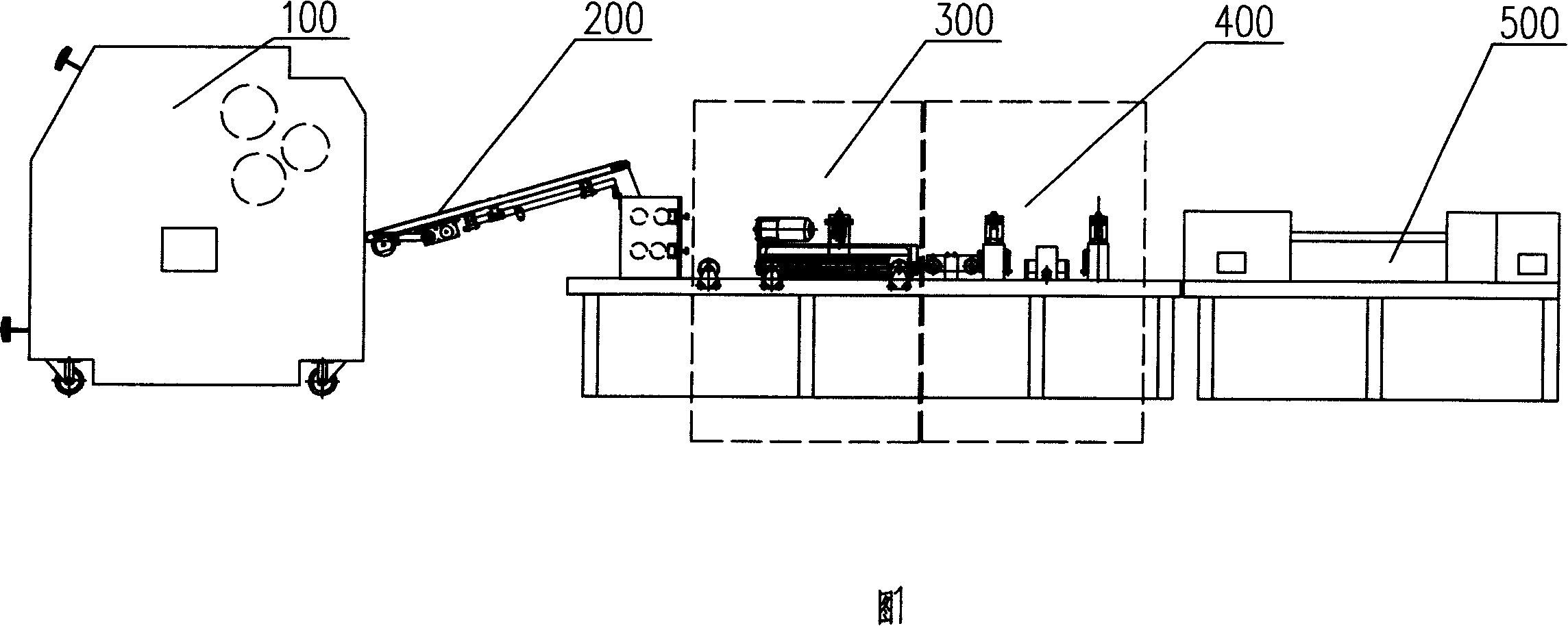

[0049] As shown in FIG. 1 , the round steamed bun production equipment of the present invention includes a sheet pressing device 100 , an inclined plane conveying device 200 , a sheet rolling device 300 , a cutting device 400 , and a forming device 500 .

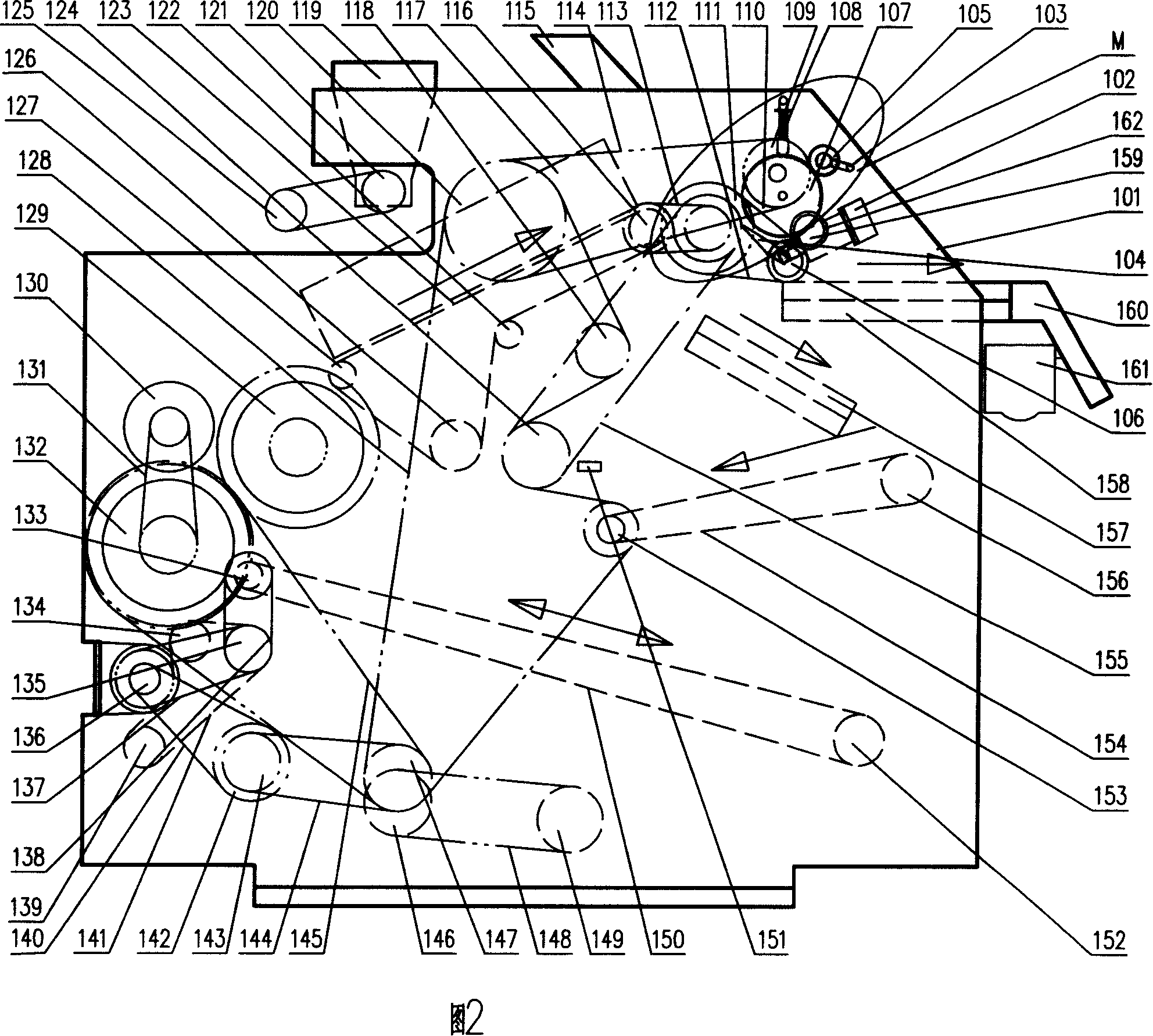

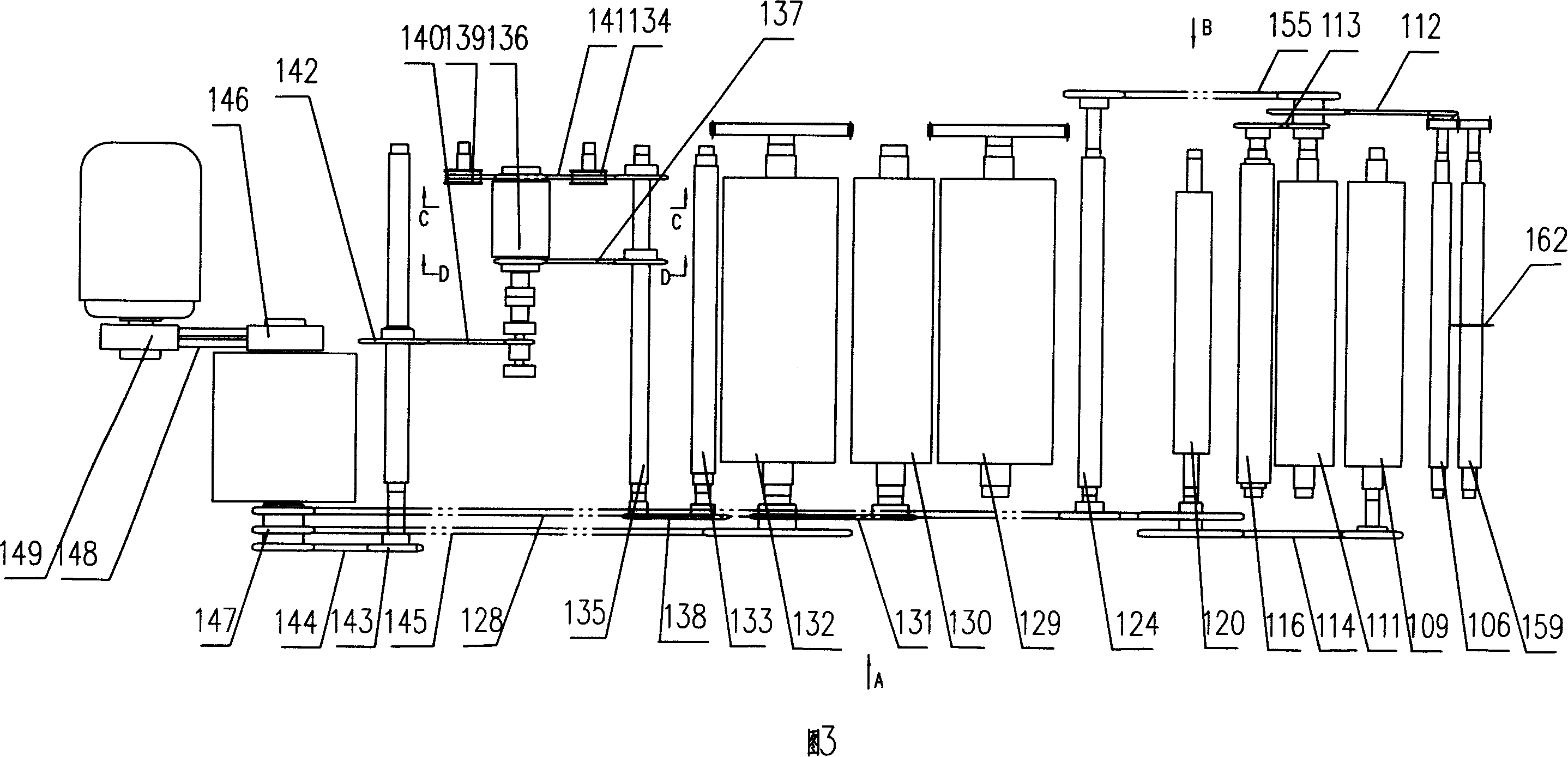

[0050] As shown in Figure 2, it is a tablet pressing device. The noodle inlet is located at the top of the machine and has a guiding guardrail 115. The bottom of the noodle inlet is the first set of rolls 109, 111, and the upper roll 109 is located at the top right of the lower roll 111. The roll 109 is installed on the eccentric disk 107 with teeth on the outer edge, and the eccentric disk 107 is connected to the cabinet 101. A sector wheel 105 with teeth is engaged with the eccentric disk 107. The lower edge of the upper roller 109 of the first group of rolls is set There are cutting and shaping rollers 106, 159, the upper roller 159 is located at the upper right of the lower roller 106, and a sheet guiding device is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com