Polyacid micro/nano-crystal fluorescent film with crystal orientation and preparation method thereof

A technology of nanocrystals and crystal plane orientation, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of loss of film order, inability to meet the thickness and quality of luminescent films, and difficulty in preparing high-quality luminescent films. Achieve the effects of non-toxic cost, simple preparation process and process equipment, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

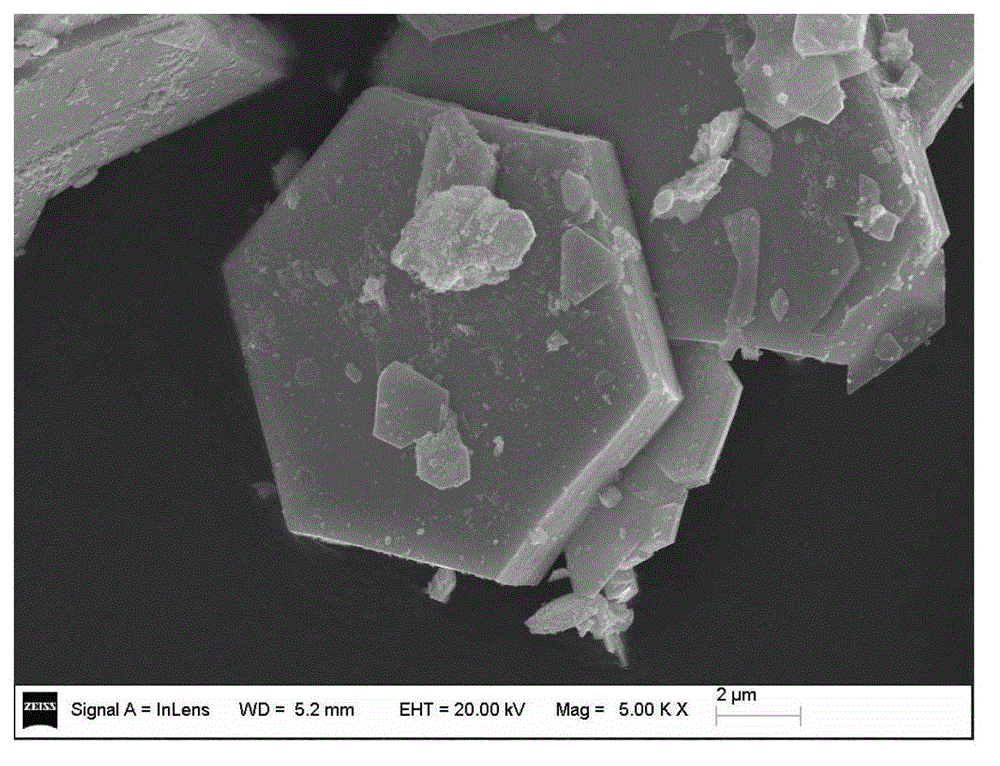

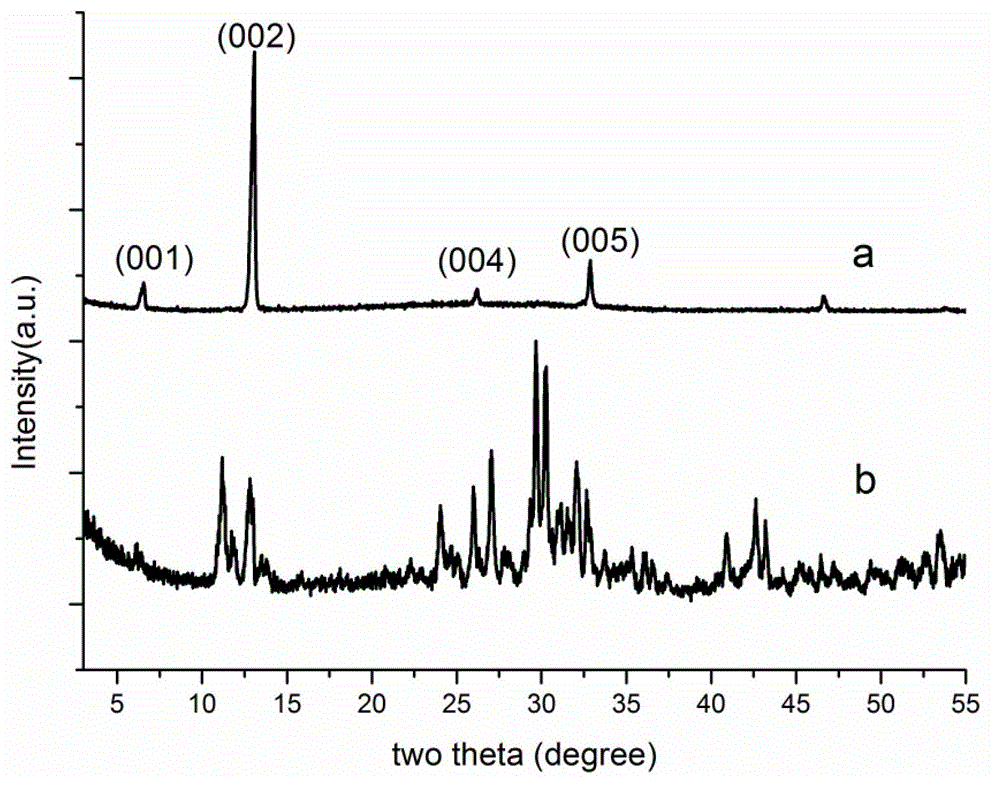

[0019] (1) Preparation of polyacid micro-nano crystals: prepare 0.005mol / L Na 9 wxya 10 o 36 32H 2 20ml of O solution and 20ml of 0.045mol / L silver nitrate solution, under the condition of 75℃ oil bath, slowly add the silver nitrate solution dropwise into the vigorously stirred Na 9 wxya 10 o 36 32H 2 O solution, centrifugal separation, the obtained product is polyacid micro-nano crystal Ag with hexagonal morphology 9 wxya 10 o 36 ;

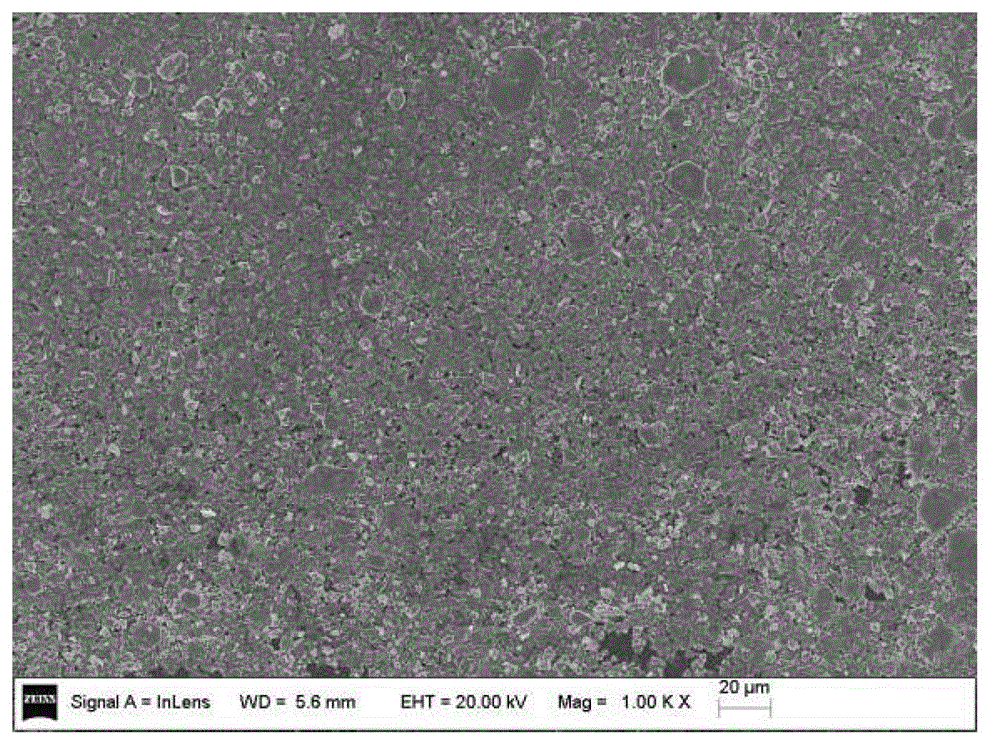

[0020] (2) Preparation of polyacid micro-nano crystal fluorescent film with crystal plane orientation: first prepare a polyethyleneimine solution with a molecular weight of 1% and a molecular weight of 55000; the prepared polyethyleneimine solution is spin-coated (2000rpm , 1min) to the surface of a clean glass sheet, the area of the glass sheet is 24×24mm 2 , with a thickness of 2mm; then put the polyacid micro-nano crystals prepared in step (1) on the surface of a glass sheet spin-coated with polyethyleneimine, rub and press for 60s...

Embodiment 2

[0023] (1) Preparation of polyacid micro-nano crystals: prepare 0.010mol / L Na 9 wxya 10 o 36 32H 2 O solution 20ml and 0.090mol / L silver nitrate solution 20ml, under the condition of 75°C oil bath, slowly drop the silver nitrate solution (40min) into the vigorously stirred (550rpm) Na 9 wxya 10 o 36 32H 2 O solution, centrifugal separation, the obtained product is polyacid micro-nano crystal Ag with hexagonal morphology 9 wxya 10 o 36 ;

[0024] (2) Preparation of multi-acid micro-nano crystal fluorescent film with crystal plane orientation: first prepare a polyethyleneimine solution with a molecular weight of 2% and a molecular weight of 55000; spin-coat 1ml of the prepared polyethyleneimine solution ( 2500rpm, 1min) to ITO glass (18×18mm 2 ) surface; then put the multi-acid micro-nano crystals prepared in step (1) on the ITO glass surface spin-coated with polyethyleneimine, and rub and press for 40s to prepare poly-acid micro-nano crystals with crystal plane orient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com