Whole wheat flour, raw material formula for whole wheat flour steamed bread, and whole wheat flour steamed bread and making method thereof

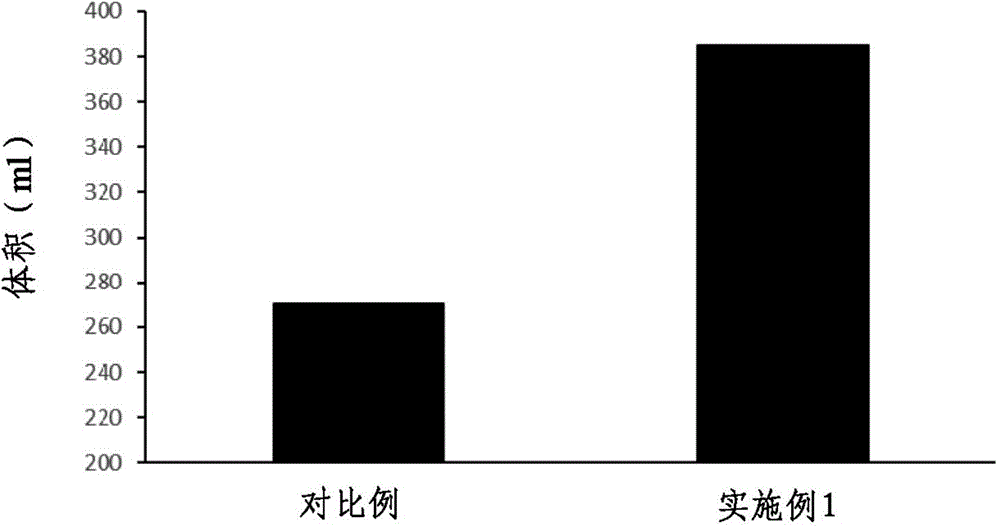

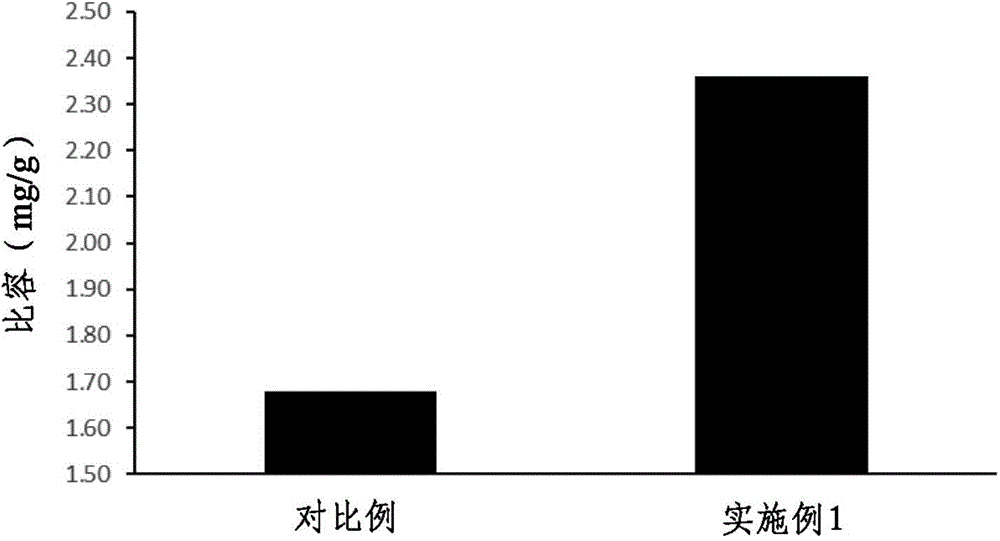

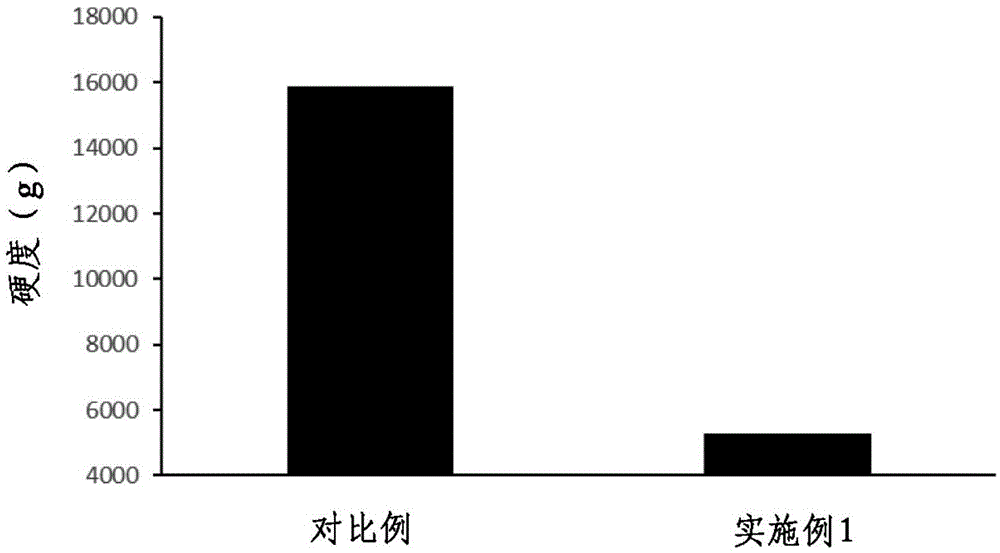

A technology of whole wheat flour and steamed bread, which is applied in the field of grain flour and grain flour cooking food processing, which can solve the problems of hard texture, small size, and poor taste, and achieve the effect of soft tissue structure, smooth surface, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The formula (percentage by weight) of each raw material used in processing the whole-wheat flour steamed bread in the present embodiment: 100 parts by weight of the above-mentioned whole-wheat flour, 5 parts by weight of white granulated sugar, 0.8 parts by weight of Angel dry yeast, gluten (Henan Lotus Flour Co., Ltd., The following examples are the same) 1.5 parts by weight, 56.5 parts by weight of water, α-amylase (model: AN301, DSM company, the following examples are the same) 9×10 -5 Parts by weight, xylanase (model: HFP, DSM, the following examples are the same) 2×10 -5 Parts by weight, lipase (model: Sublime, DSM, the following examples are the same) 5×10 -5 parts by weight.

[0048] Wherein, in the whole wheat flour,

[0049] (a) flour with a wet gluten content > 30%,

[0050] (b) Wheat bran powder with particle size < 100 μm after extruded ultrafine grinding, and

[0051] (c) Wheat germ powder with a particle size of <100 μm after superfine pulverizat...

Embodiment 2

[0054] The formula (percentage by weight) of each raw material used in processing the whole-wheat flour steamed bread in the present embodiment: 100 parts by weight of the above-mentioned whole-wheat flour, 5 parts by weight of white granulated sugar, 0.8 parts by weight of Angel dry yeast, 2.5 parts by weight of gluten powder, and 57.5 parts by weight of water Servings, α-amylase 6×10 -5 parts by weight, xylanase 3.5×10 -5 parts by weight, lipase 1×10 -4 parts by weight.

Embodiment 3

[0056] The formula (percentage by weight) of each raw material used in processing the whole-wheat flour steamed bread in the present embodiment: 100 parts by weight of the above-mentioned whole-wheat flour, 0 parts by weight of white granulated sugar, 0.5 parts by weight of Angel dry yeast, 3.5 parts by weight of gluten powder, and 58.5 parts by weight of water Servings, α-amylase 9×10 -5 parts by weight, xylanase 5×10 -5 parts by weight, lipase 1.5×10 -4 parts by weight.

[0057] The processing steps of the wholemeal steamed bread of processing embodiment 1-3 are as follows:

[0058] (a) Raw material mixing, kneading and molding

[0059] First whole wheat flour, gluten, alpha-amylase, xylanase, lipase are mixed uniformly by the ratio listed in embodiment 1-3, then, add dry yeast and the warm water that contains white granulated sugar according to above-mentioned ratio (25 -38℃), use a glass rod or chopsticks to mix into a dough, knead it by hand for 4 minutes, let it stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com