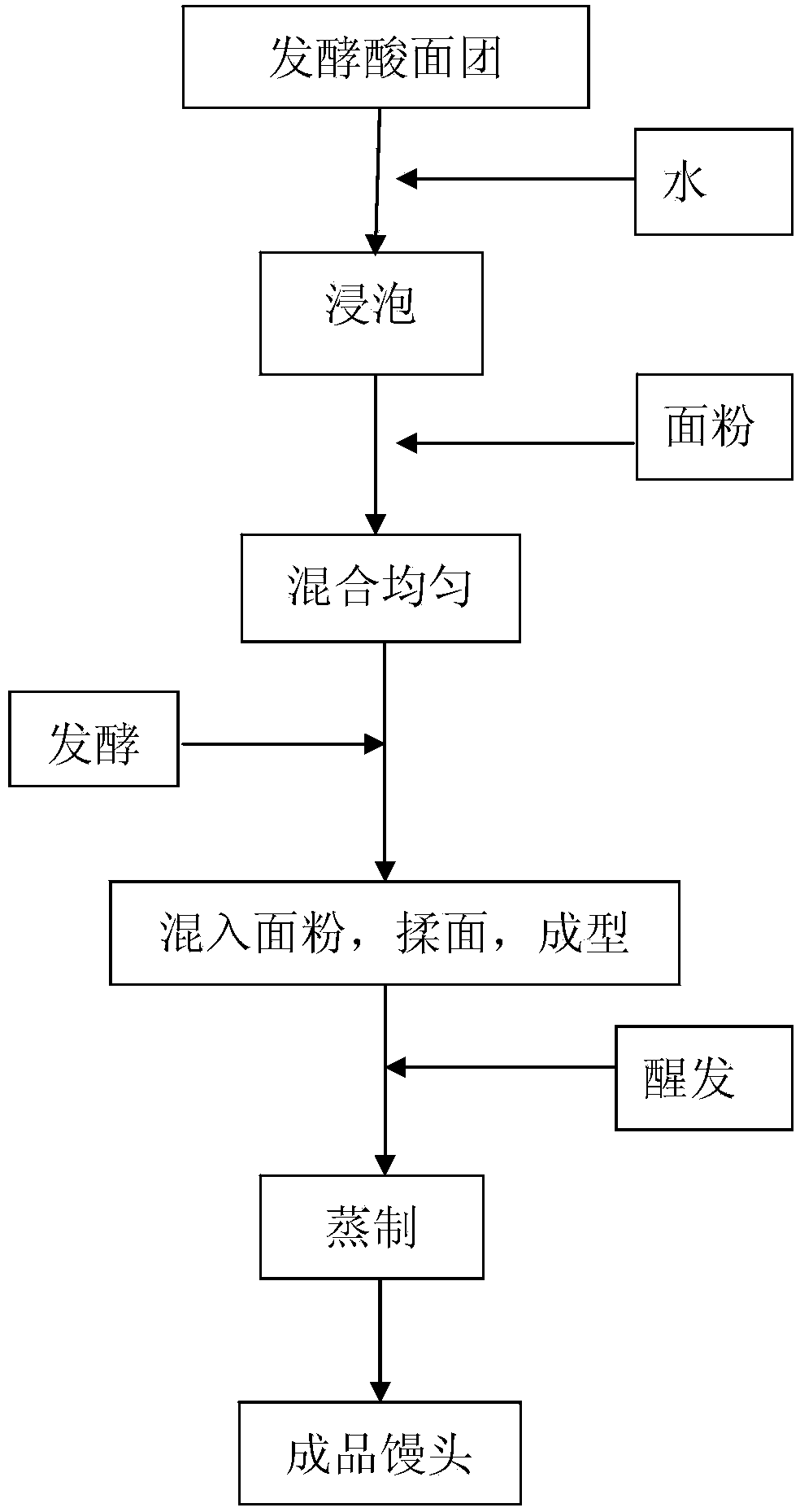

Method for making steamed buns by fermented sour dough

A technology for fermenting sourdough and steamed bread, which is applied in the field of fermented flour products, can solve problems such as pH detection error, and achieve the effects of good flavor, good taste, and avoiding difficult quantification of alkali dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 1 kg of fermented sourdough, add 0.3 kg of water to soak for 15 minutes, add 0.6 kg of wheat flour, mix well, and ferment at a temperature of 30°C and a relative humidity of 75%. After 3 hours, add 1.2 kg of wheat flour and 0.6 kg of water , and then knead the dough for about 12 minutes. After the dough is smooth and not sticky, divide, round, and shape it. Place it at 30°C and a relative humidity of 75% for proofing for 60 minutes. After steaming for 33 minutes, the finished steamed buns are obtained.

[0026] Its scores are: surface specific volume (13), aspect ratio (4), color (5), taste (8), internal structure (12), appearance shape (8), elasticity (7), toughness (7), Odor (9), stickiness (8), total score 81 points.

Embodiment 2

[0028] Weigh 1 kg of fermented sourdough, add 0.5 kg of water to soak for 10 minutes, add 0.8 kg of wheat flour, mix well, and ferment at a temperature of 28°C and a relative humidity of 70%. After 3.5 hours, add 1.0 kg of wheat flour and 0.5 kg of water kg, and then knead the dough for about 10 minutes. After the dough is smooth and non-sticky, divide, round, and shape it. Place it at 28°C and a relative humidity of 70% for proofing for 40 minutes, and steam for 30 minutes to get the finished steamed bun.

[0029] The scores are: surface specific volume (10), aspect ratio (3), color (4), taste (7), internal structure (12), appearance shape (7), elasticity (6), toughness (8), Odor (9), stickiness (7), total score 75 points.

Embodiment 3

[0031] Weigh 1 kg of fermented sourdough, add 0.4 kg of water to soak for 12 minutes, add 0.7 kg of wheat flour, mix well, and ferment at a temperature of 32°C and a relative humidity of 80%. After 4 hours, add 1.5 kg of wheat flour and 0.8 kg of water , and then knead the dough for about 15 minutes. After the dough is smooth and non-sticky, divide, round, and shape it. Place it at 32°C and 80% relative humidity for proofing for 70 minutes. After steaming for 35 minutes, the finished steamed buns are obtained.

[0032] Its scores are: surface specific volume (11), aspect ratio (5), color (4), taste (6), internal structure (9), appearance shape (5), elasticity (5), toughness (7), Odor (8), stickiness (9), total score 69 points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com