Method of prolonging preservation period of steamed bread

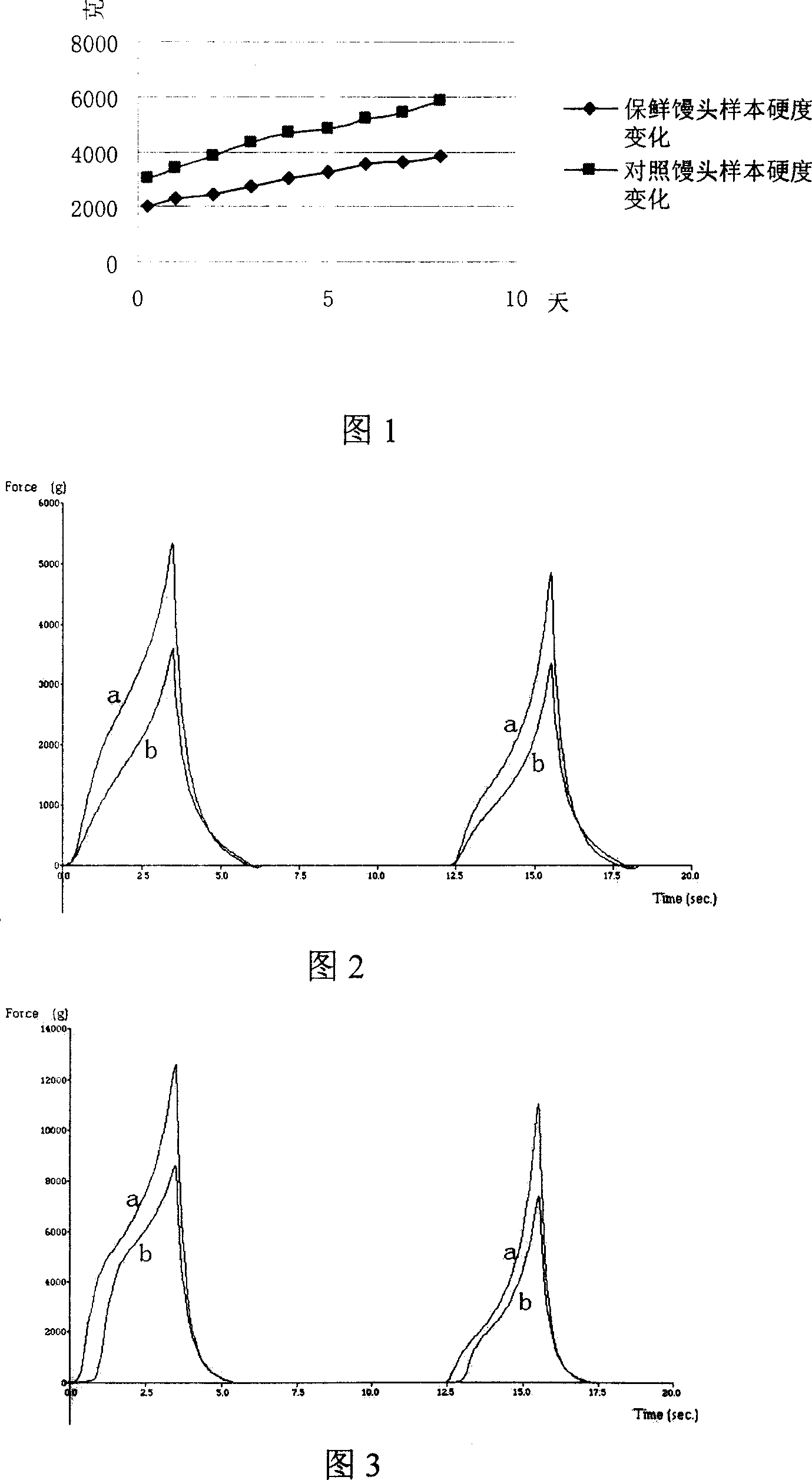

A technology for preservation period and steamed bread, applied in the field of food preservation, can solve the problems of high cost, secondary pollution of steamed bread, small radius, etc., and achieve the effects of avoiding gluten damage, hindering water loss and improving gelatinization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, the anti-aging compound improver is made up of the raw material of following percentage by weight: fungal α-amylase 2%, xylanase 3%, phospholipase 4%, stearoyl lactylate calcium sodium 50%, monostearic acid Glyceride 10%, Sodium Carboxymethyl Cellulose 27%, Tricalcium Phosphate 4%.

[0032] The composite biological antifungal agent is composed of the following raw materials in weight percentage: 25% of nisin, 50% of polylysine, and 25% of natamycin.

[0033] Preparation of fresh-keeping steamed bun samples of the present invention: pre-mix flour, active dry yeast with 1% flour content, and anti-aging compound improver with 1‰ flour content in a dough mixer for 3 minutes, then add water and knead into a dough. After the dough is continuously folded and pressed 10 times on the tablet machine, it is rolled into dough rolls, divided and rolled into round shapes. Put the molded steamed bun base into a proofing box with a temperature of 37°C and a supersaturate...

Embodiment 2

[0039] Embodiment 2, the anti-aging compound improver is made up of the raw material of following percentage by weight: bacterial α-amylase 1%, xylanase 7%, lipohydrolase 3%, calcium sodium stearoyl lactylate 50%, monostearin Glyceryl Acid 20%, Sodium Carboxymethyl Cellulose 15%, Silicon Dioxide 4%.

[0040] The composite biological antifungal agent is composed of the following raw materials in weight percentage: 30% of nisin, 30% of polylysine and 40% of natamycin.

[0041] Preparation of fresh-keeping steamed bun samples of the present invention: pre-mix flour, active dry yeast with 1% flour content, and anti-aging compound improver with 5‰ flour content in a dough mixer for 3 minutes, then add water and knead to form a dough. After the dough is continuously folded and pressed 5 times on the tablet machine, it is rolled into dough rolls, divided and rolled into round shapes. Put the molded steamed bun base into a proofing box with a temperature of 38°C and a supersaturated ...

Embodiment 3

[0047] Embodiment 3, the anti-aging compound improver is made up of the raw material of following percentage by weight: Glucoamylase 3%, pentosanase 5%, phospholipase 7%, diacetyl tartaric acid monoglyceride 39%, monostearic acid glyceryl 20%, konjac flour 20%, tricalcium phosphate 6%.

[0048] The composite biological antifungal agent is composed of the following raw materials in weight percentage: nisin 40%, polylysine 30%, natamycin 30%.

[0049] Preparation of fresh-keeping steamed bun samples of the present invention: pre-mix flour, active dry yeast with 1% flour content, and anti-aging compound improver with 2% flour content in a dough mixer for 3 minutes, then add water and knead into a dough. After the dough is continuously folded and pressed 20 times on the tablet machine, it is rolled into dough rolls, divided and rolled into round shapes. Put the molded steamed bun base into a proofing box with a temperature of 35°C and a supersaturated humidity for 45 minutes, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com