Preparing method of noodle rich in Fe, Zn, and Se and its preparing technique

A production process and technology of selenium nutrition, which is applied in the field of production process of iron-zinc-selenium nutrition noodles, can solve problems such as difficult absorption, and achieve the effects of favorable absorption, good biological activity and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

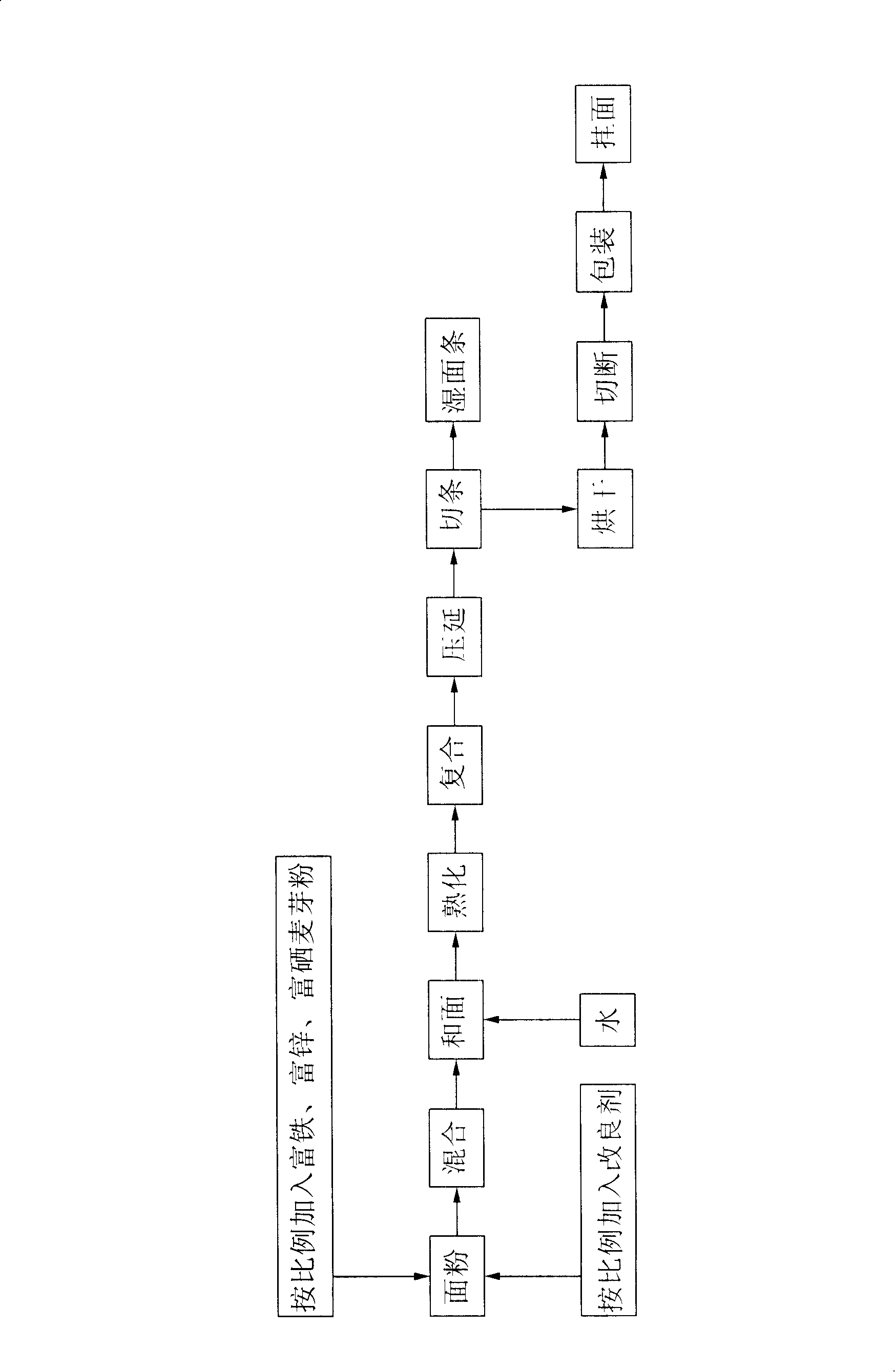

Method used

Image

Examples

Embodiment 1

[0021] Start by making iron-enriched malt powder, zinc-enriched malt powder, and selenium-enriched malt powder.

[0022] Iron-rich malt powder is made according to the following process:

[0023] a. Put a certain amount of wheat into 200mg / kg ferrous sulfate aqueous solution, soak the wheat at 24°C for 6 hours and then drain;

[0024] b. Germinate for 4 days at 25°C, and soak in ferrous sulfate solution of the same concentration for 10 minutes every 12 hours during the first 2 days of germination;

[0025] c. After 2 days, change to showering and stirring with water every morning and evening, so that the temperature of the wheat layer can be properly cooled, and at the same time, fresh air is introduced and CO is discharged. 2 gas;

[0026] After d, 4 days, after the bud grows to 1.5cm, stop the germination cultivation;

[0027] e. Soak in deionized water at 30°C for 3.5 hours, then rinse with deionized water several times to remove inorganic salts attached to the surface o...

Embodiment 2

[0042] Start by making iron-enriched malt powder, zinc-enriched malt powder, and selenium-enriched malt powder.

[0043] Iron-rich malt powder is made according to the following process:

[0044] a. Put a certain amount of wheat into 250mg / kg ferrous sulfate aqueous solution, soak the wheat at 25°C for 8 hours and then drain;

[0045] b. Germinate for 4 and a half days at 25°C, and soak in ferrous sulfate solution of the same concentration for 10 minutes every 12 hours during the first 2 days of germination;

[0046] c. After 2 days, change to showering and stirring with water every morning and evening, so that the temperature of the wheat layer can be properly cooled, and at the same time, fresh air is introduced and CO is discharged. 2 gas;

[0047] After d, 4 and a half days, after the bud grows to 1.8cm, stop the germination cultivation;

[0048] e. Soak in deionized water at 30°C for 3 hours and 45 minutes, then rinse with deionized water several times to remove inorga...

Embodiment 3

[0063] Start by making iron-enriched malt powder, zinc-enriched malt powder, and selenium-enriched malt powder.

[0064] Iron-rich malt powder is made according to the following process:

[0065] a. Put a certain amount of wheat into 300mg / kg ferrous sulfate aqueous solution, soak the wheat for 10 hours at 24-25°C and drain;

[0066] b. Germinate for 5 days at 25°C, soak in ferrous sulfate solution of the same concentration for 10 minutes every 12 hours during the first 2 days of germination;

[0067] c. After 2 days, change to showering and stirring with water every morning and evening, so that the temperature of the wheat layer can be properly cooled, and at the same time, fresh air is introduced and CO is discharged. 2 gas;

[0068] After d, 5 days, after the bud grows to 2cm, stop the germination cultivation;

[0069] e. Soak in deionized water at 30°C for 4 hours, then rinse with deionized water several times to remove inorganic salts attached to the surface of malt, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com