Manufacturing method of tungsten target material

A production method and target technology, which are applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of easy oxidation of the surface of tungsten target blank, hard and brittle tungsten target blank, and difficult processing, etc. To achieve the effect of uniform internal structure, low scrap rate and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

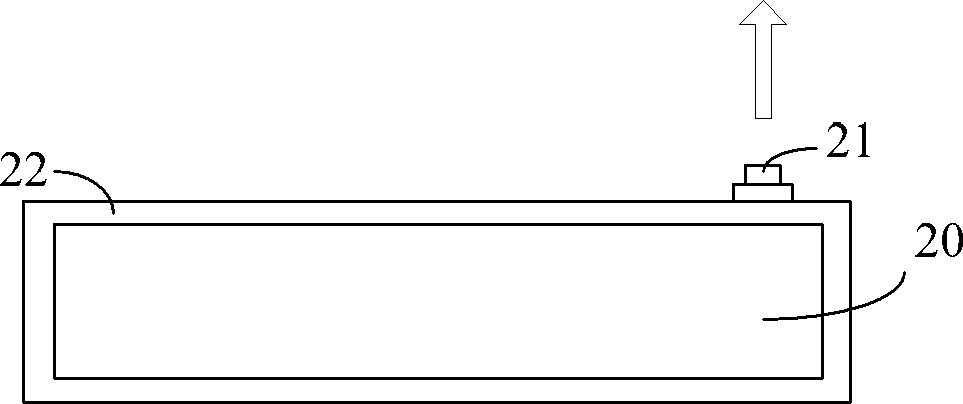

[0036] The manufacturing method of the tungsten target material provided by the present invention avoids the problems of cracks and easy oxidation of the surface when the tungsten target blank is processed and extended in the air, and can produce a uniform internal structure and a large grain size. The tungsten target meets the requirements of sputtering target, and has the advantages of easy processing and low scrap rate.

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

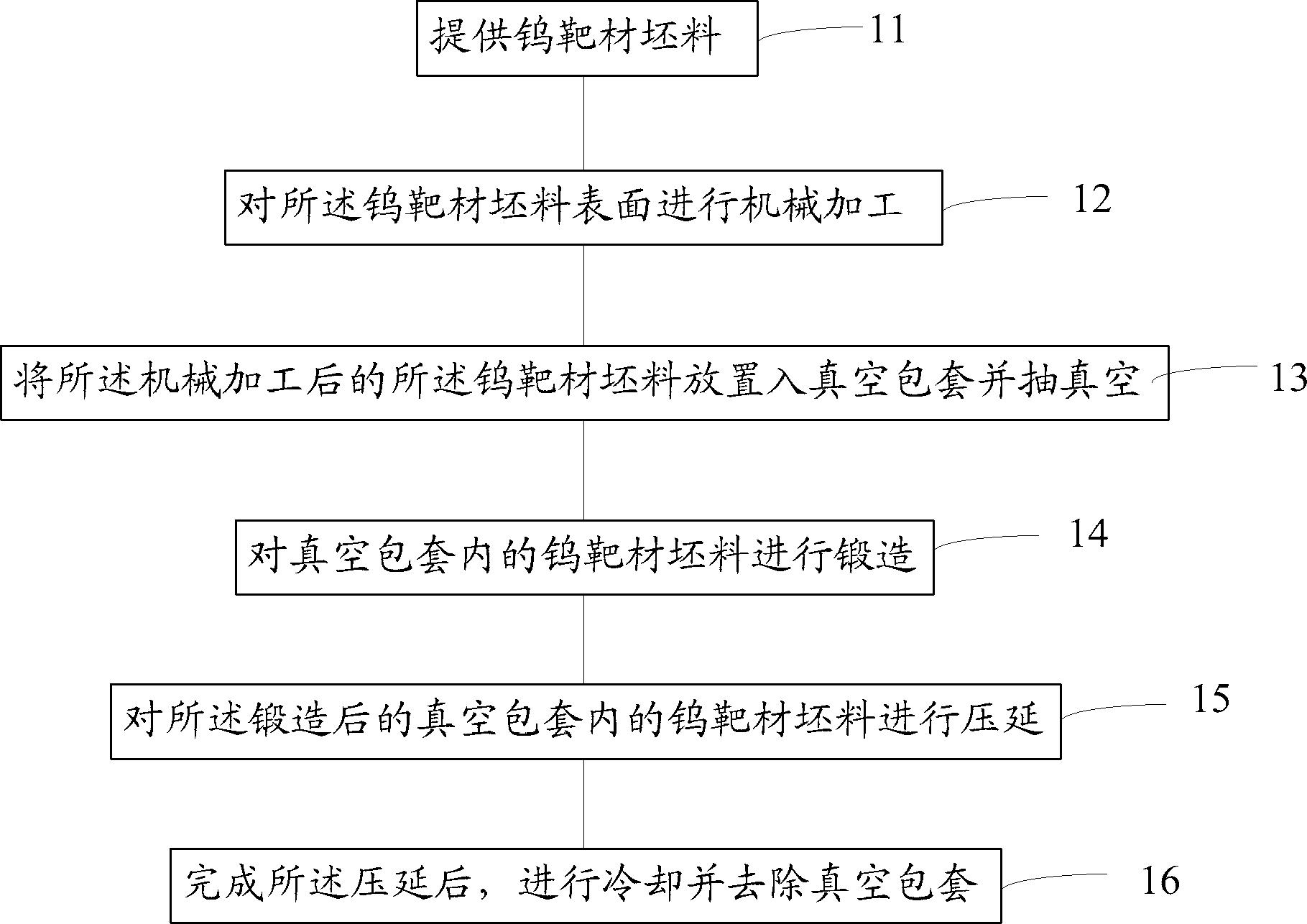

[0038] figure 1 Shown is the flow chart of the manufacturing method of the tungsten target material provided by the present invention, combined below figure 1 , to introduce the specific embodiment of the present invention in detail.

[0039]First, step S11 is performed to provide a tungsten target blank.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com