Anti-bending multimode fiber and manufacturing method thereof

A technology of multimode optical fiber and manufacturing method, applied in the field of optical communication, can solve the problem that the refractive index distribution of optical fiber is difficult to maintain a perfect parabola, and achieve the effects of eliminating internal stress, improving bending resistance and improving mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] According to the method of the present invention, a group of preforms are prepared and drawn, and the double-layer coating of multimode optical fiber and the drawing speed of 600 m / min are adopted. The structure and material composition of the optical fiber are shown in Table 1, and the main performance parameters of the optical fiber are shown in Table 1. Table 2.

[0051] The macrobending additional loss is measured according to the method of FOTP-62 (IEC-60793-1-47). On, test the change of optical power before and after the circle, and use it as the macrobending additional loss of the fiber. During the test, an Encircled Flux (Encircled Flux) light injection condition was used. Encircled Flux (Encircled Flux) light injection conditions can be obtained by the following method: Splice a 2-meter-long ordinary 50-micron core diameter multimode fiber at the front end of the fiber under test, and wind a 25 mm diameter circle in the middle of the fiber, when When full inj...

Embodiment 2

[0055] This embodiment is an example of correcting and compensating the refractive index distribution of the prefabricated rod according to the refractive index distribution of the optical fiber, so as to manufacture a multimode optical fiber with precise refractive index distribution.

[0056] According to the preliminarily designed refractive index distribution of the multimode optical fiber preform, the gaseous SiCl 4 、GeCl 4 、C 2 f 6 and O 2 A quartz glass liner is introduced and the deposition takes place inside the tube. SiCl 4 、GeCl 4 and O 2 The supply of C varies with time, while C 2 f 6 supply remains constant. After the deposition is completed, it is melted into a solid rod, and the refractive index distribution of the preformed rod is tested, and the preformed rod is drawn into an optical fiber. Then carry out the refractive index distribution test on the optical fiber, and compare the test results with the required refractive index distribution of the pr...

Embodiment 3

[0060] In order to illustrate the effect of the present invention, some optical fiber samples were made according to the optical fiber section structure and material composition described in the U.S. patent by using PCVD technology, and the dynamic fatigue parameter n d test. In order to eliminate the influence of the coating layer on the test results, all optical fibers use the same type of coating layer with similar size. The fiber drawing speed and drawing tension are also basically the same.

[0061] Test A:

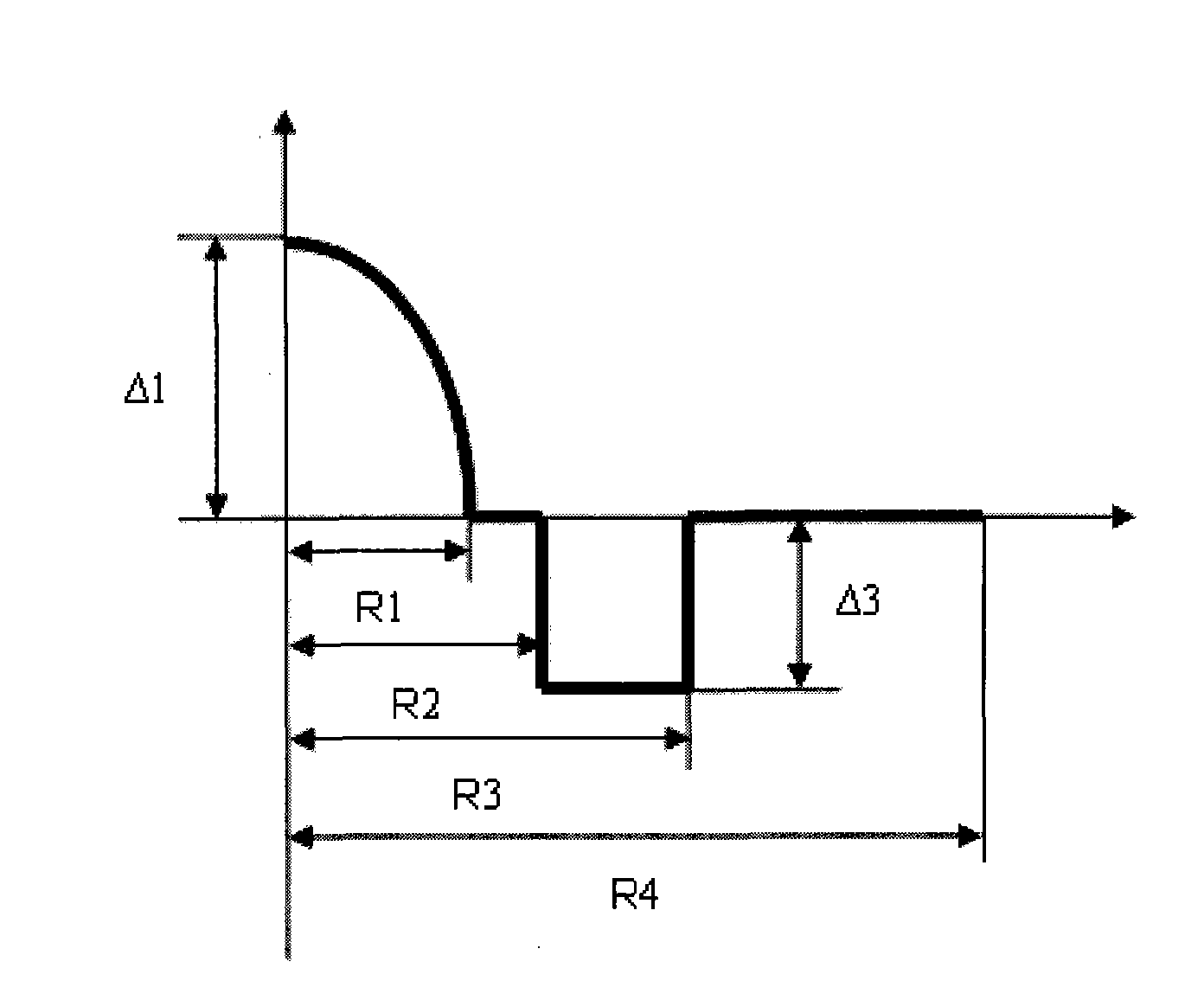

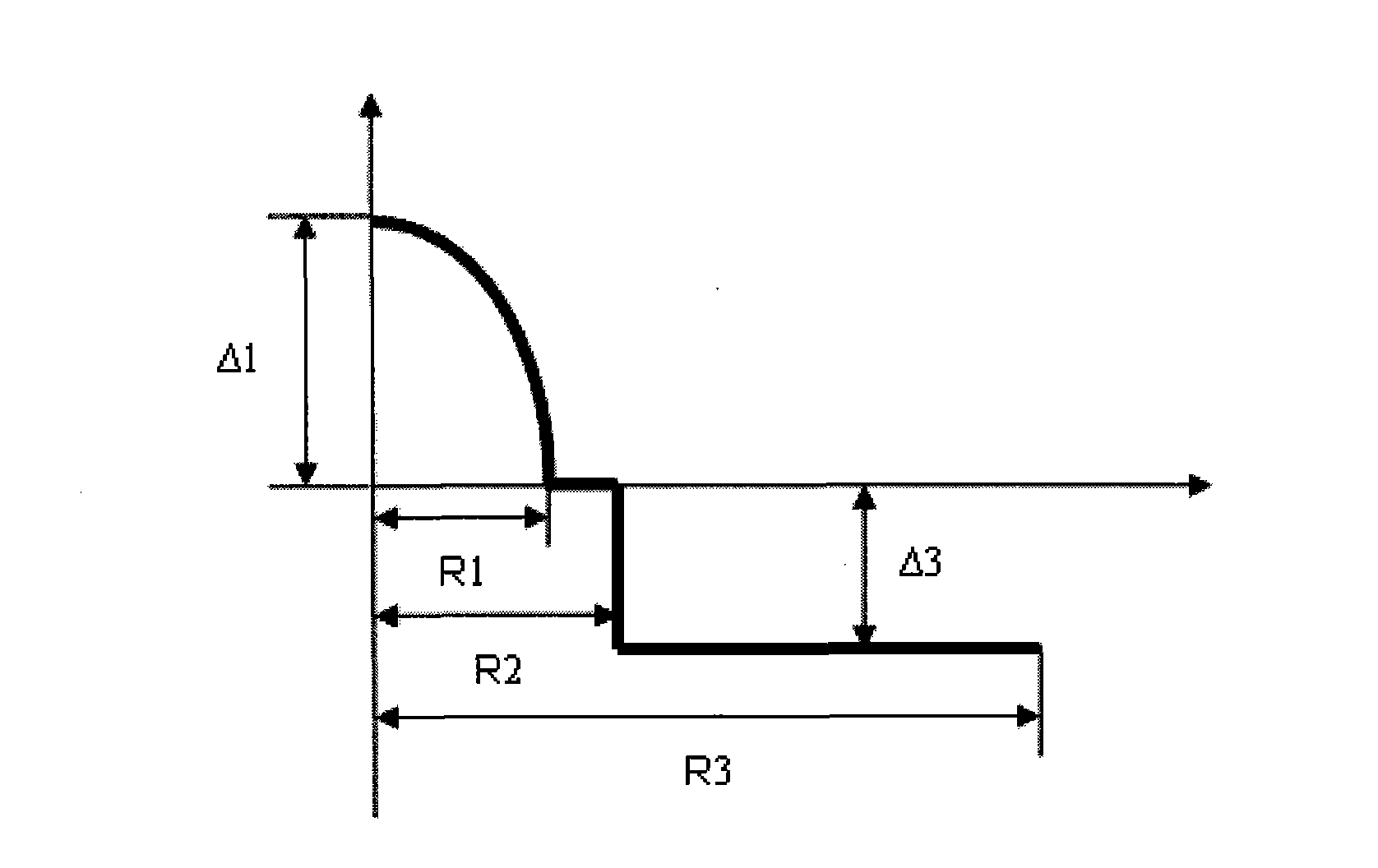

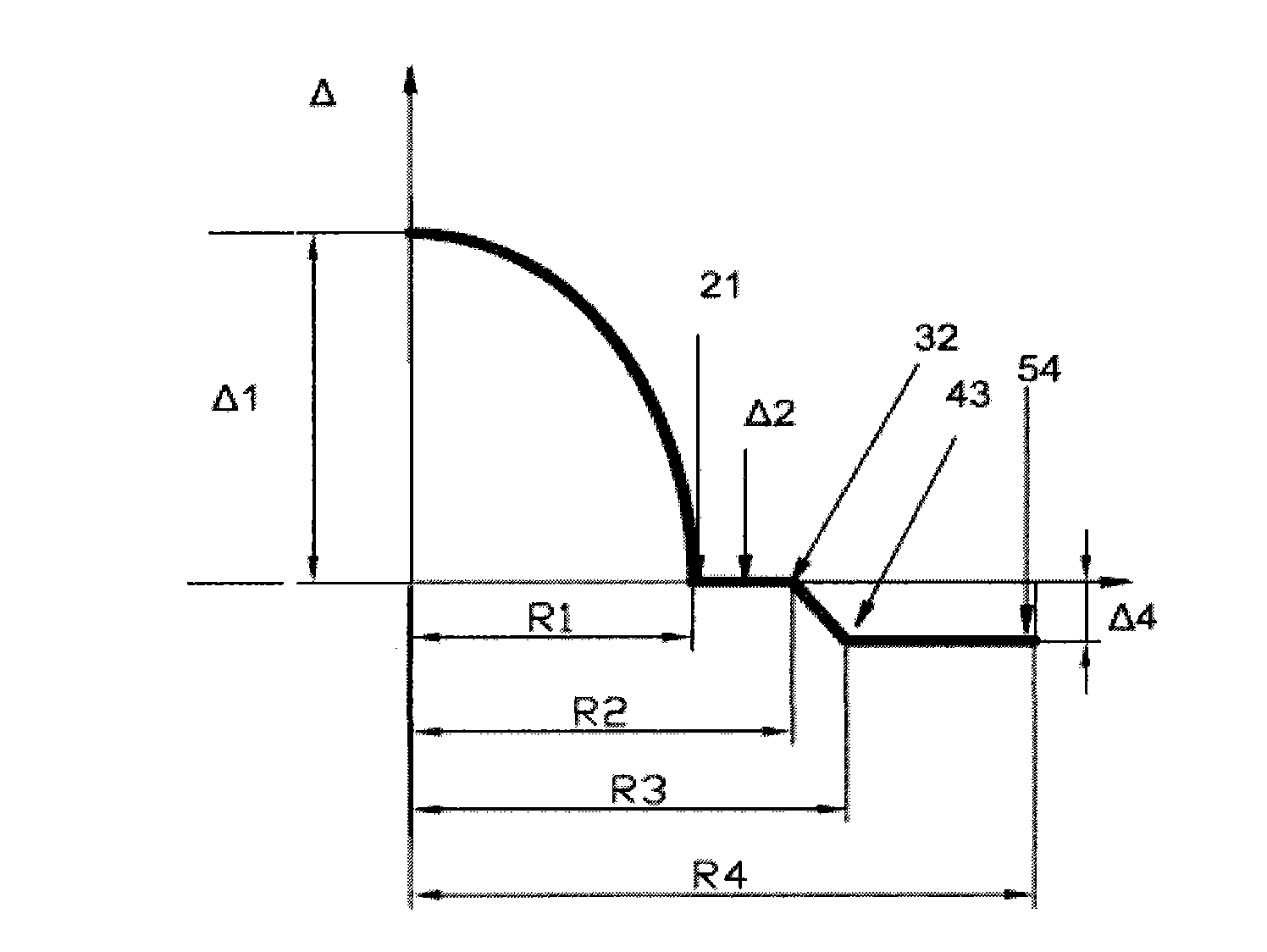

[0062] Some refractive index profiles were fabricated by PCVD process such as figure 1 Fiber samples are shown, and a n d test. The test process and fiber test results are as follows:

[0063] The pure quartz glass liner was fixed on a plasma-enhanced chemical vapor deposition (PCVD) lathe for dopant deposition, and the reaction gas silicon tetrachloride (SiCl 4 ) and oxygen (O 2 ), the reaction gas in the liner is ionized by microwaves into plasma, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com