Method for replacing crane steel wire ropes

A replacement method and technology of steel wire rope, applied in the direction of spring mechanism, winch device, etc., can solve the problems of distortion, broken wire, accidents, etc., and achieve the effect of eliminating internal stress and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

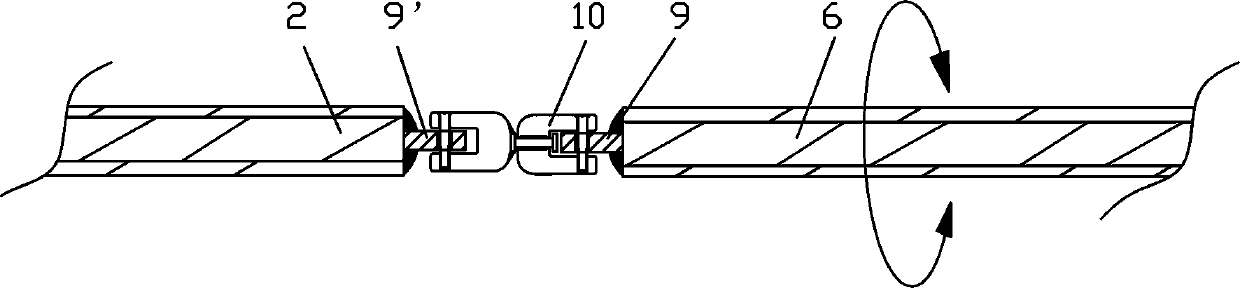

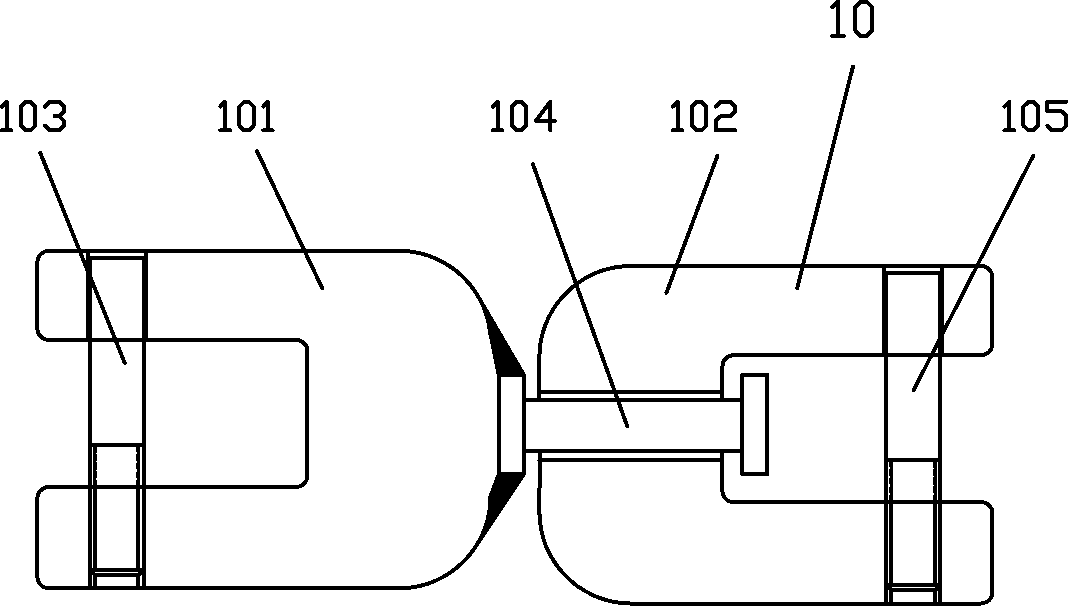

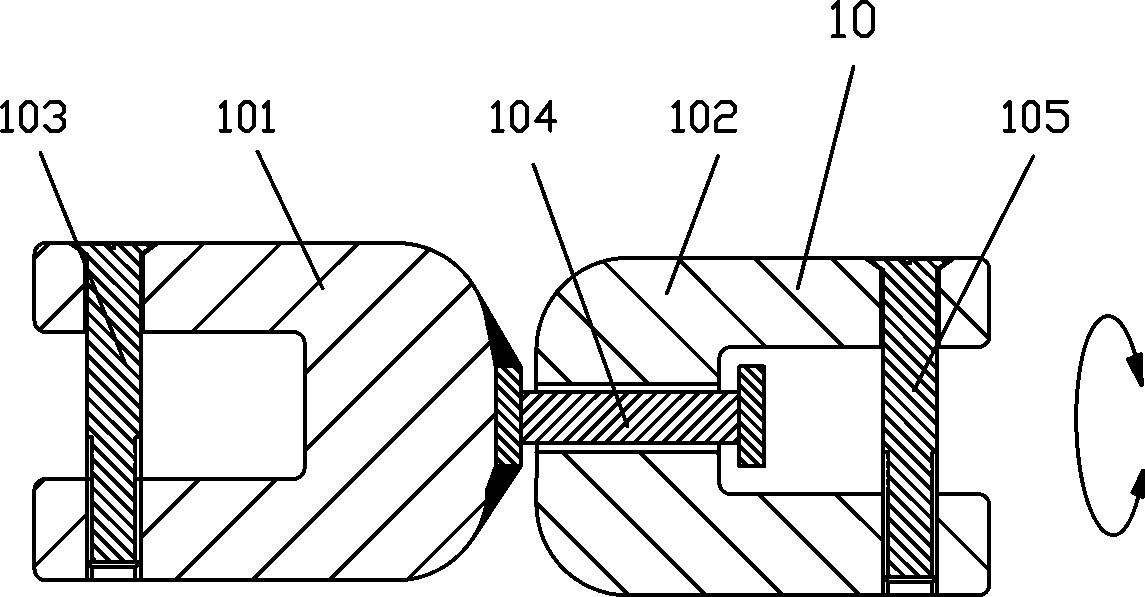

[0026] see Figure 1 to Figure 5 , the replacement method of crane wire rope of the present invention, it comprises the steps:

[0027] a) Put the crane hook 1 on the ground, place a wire rope drum 3, 3' and the corresponding support on both sides of the hook 1, and place a new wire rope 2, 2' and the corresponding support. The hook 1 and the wire rope drum 3, The distance between 3' is controlled at 3-4 meters, and the rotation of the wire rope drum and the release of the new wire rope are ensured;

[0028] b) The hoisting mechanism 4 of the crane drives the wire rope reel 5 to rotate, and releases the old wire ropes 6, 6' of the wire rope reel 5, so that the old wire ropes 6, 6' are completely relaxed, and the old wire ropes 6, 6' remain on the wire rope reel 5 The number of rope loops is 2 to 3 (excluding the fixed loop of the reel wire rope);

[0029] c) Cut off the two steel wire ropes 6, 6' between the steel wire rope balance frame 7, 7' on both sides of the fixed pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com