Full-power control ingot casting process for polycrystalline silicon ingot furnace

A polycrystalline silicon ingot furnace, full power control technology, applied in the direction of polycrystalline material growth, single crystal growth, crystal growth, etc., can solve the problems of uneven thermal stress, uneven thermal field, temperature fluctuation, etc., to eliminate internal stress , conducive to growth, the effect of constant thermal field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

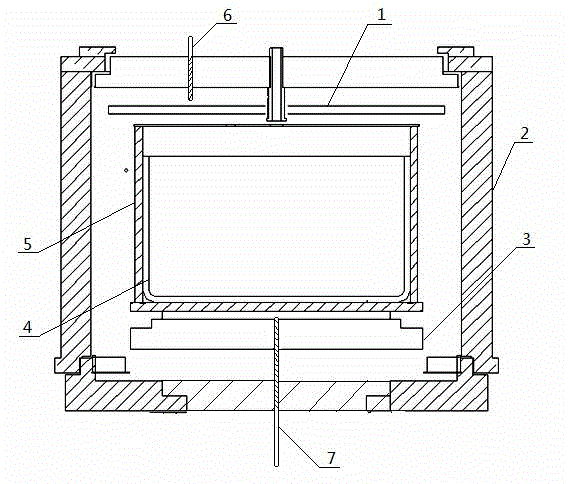

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] like figure 1 As shown, the present invention is a polysilicon ingot casting furnace full-power control ingot casting process, which completely uses power and time control to complete the five stages of heating, melting, crystal growth, annealing and cooling in the ingot casting process; the heating stage and the melting stage The end of the process is alerted by the predetermined set temperature reached by the first thermocouple above the heater and the second thermocouple below the quartz crucible; each stage is divided into several steps for power and time control; finally the finished product is produced.

[0034] The model of the polysilicon ingot casting furnace is JJL500N or JJL800;

[0035] The heating stage: heating up the silicon material, the process steps are as follows;

[0036] Step 1: Set the heater power of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com