Precise U-shaped bending die for magnesium alloy sectional materials

A technology of precision molds and magnesium alloys, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the stress of profiles, deformation and fracture of magnesium alloy profiles, and collapse of bending parts, so as to solve the problems of magnesium alloy deformation and fracture, profile Improve the spacing accuracy and ensure the effect of the internal organization structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

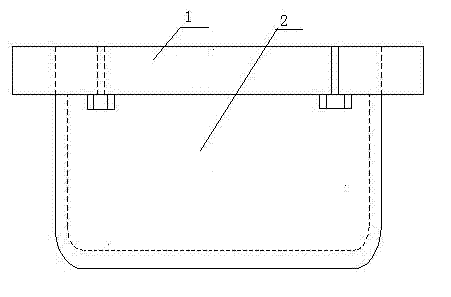

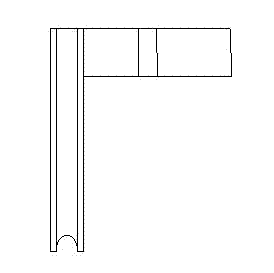

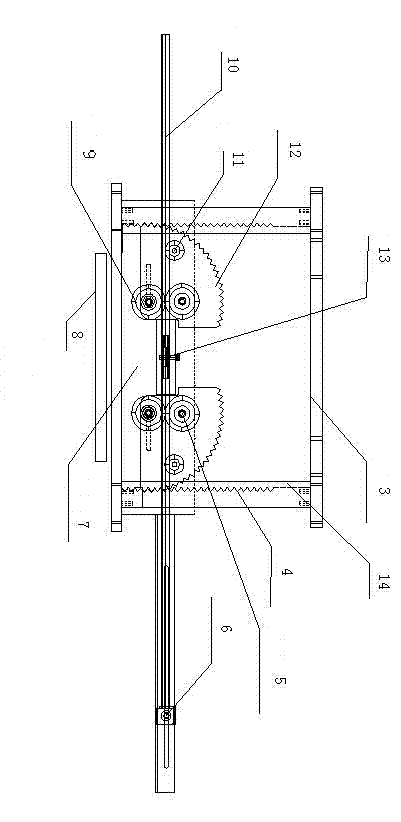

[0024] Example: figure 2 As shown, the present embodiment includes an upper mold frame and a lower formwork, and the upper mold frame is composed of an upper beam plate 3, a lower beam square iron 16 and two refined racks 4 to form a rectangular frame, wherein the upper beam plate 3 is located at the lower beam square iron 16 Above, the upper beam plate 3 is parallel to the lower beam square iron 16 and is horizontally arranged, and the two precision racks 4 are perpendicular to the upper beam plate 3 and the lower beam square iron 16 and are arranged on the upper beam plate 3 and the lower beam square iron 16. At both ends, two precision racks 4 are fixedly connected to the upper beam plate 3 and the lower beam square iron 16 to form a rectangular frame; a limit plate 14 is set behind the precision rack 4, and the rotating toothed plate 12 meshes with the precision rack 4 , the limit plate 14 is used to limit the rotation of the toothed disc 12, which can prevent the toothed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com