Method for repairing lining plate-free flat-head cap of spindle of rolling mill

A repair method and a technology of flat headgear, which are applied to the driving device for metal rolling mills, metal rolling, metal rolling, etc., can solve the problems of high rolling safety factor, increased maintenance costs, etc., to improve service life and reduce Overhaul costs, guaranteed automation and effect on finished product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

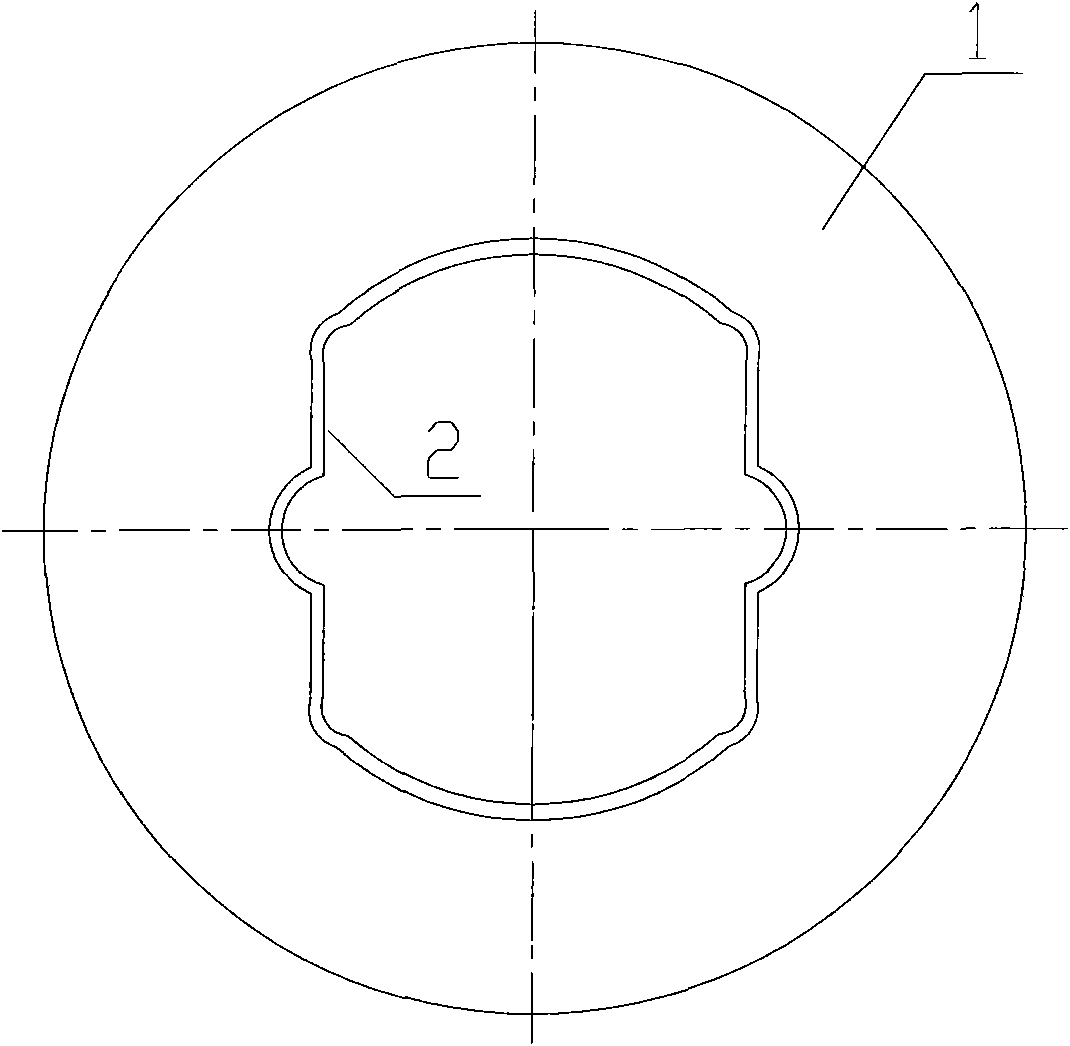

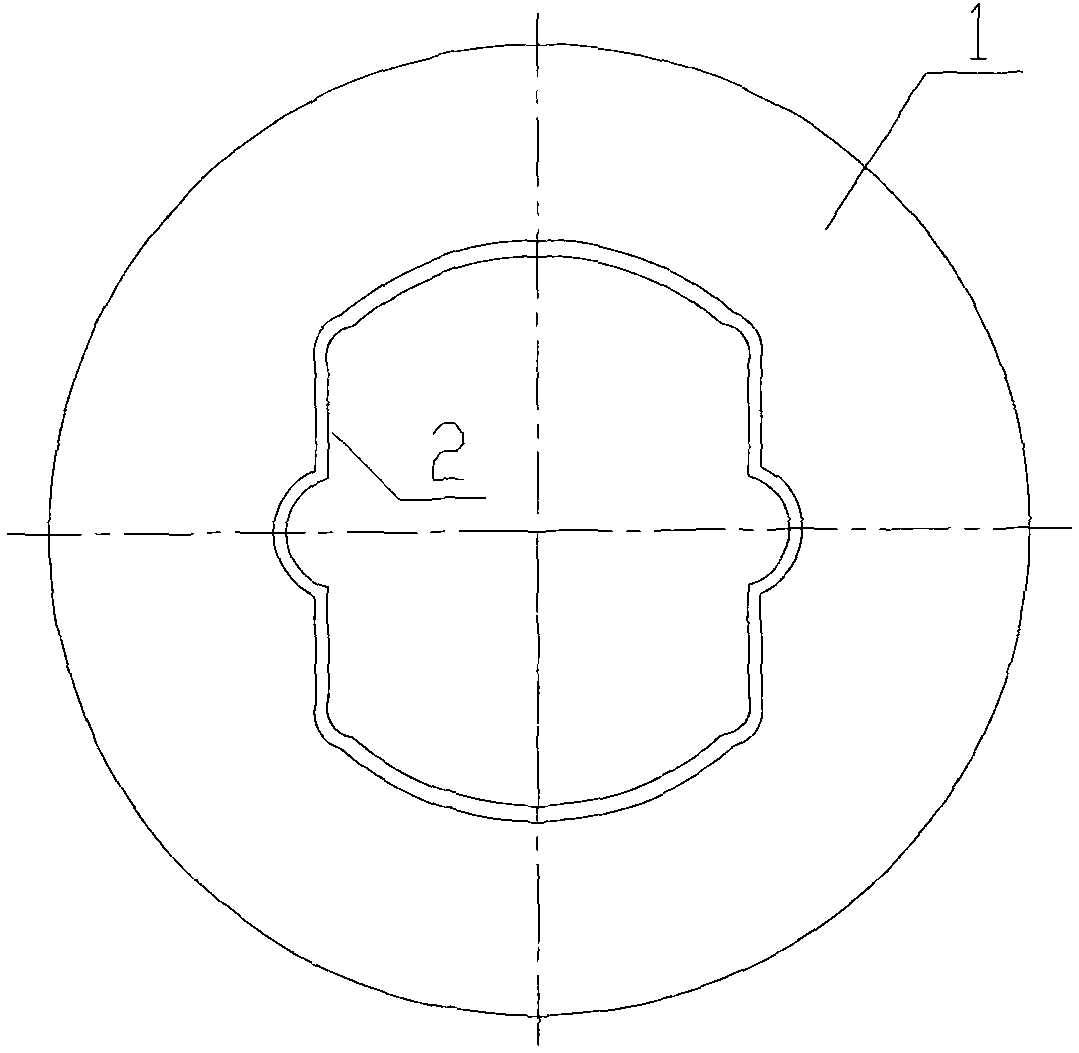

[0020] Such as figure 1 As shown, there are flat surfaces 2 on both sides of the inner hole of the unlined flat headgear 1. After the rolling mill runs for a certain period of time, the flat surface 2 wears out and causes the flat headgear 1 to fail. The present invention provides a repair method.

[0021] The repair method of the rolling mill spindle without liner flat head cover of the present invention comprises the following steps:

[0022] Step 1. Check and record the wear state of the flat surface of the flat hood without lining;

[0023] Step 2: Perform stress-relief annealing on the unlined flat hood, and use 260°C for 12 hours for stress-relief annealing to release and homogenize the huge internal stress of the unlined flat hood;

[0024] Step 3: Inductively anneal the flat surface of the unlined flat hood to reduce the hardness of the carburized and quenched layer on the flat surface of the unlined flat hood without affecting the overall strength of the entire flat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com