Tyre retreading sidewall sanding device and sanding method thereof

A tire retreading and sidewall technology, which is applied in the direction of grinding machines, grinding/polishing equipment, and machine tools suitable for grinding workpiece planes, etc., can solve the problems of heavy workload and inconspicuous treatment effect, and achieve improved performance and release Effects of labor load and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

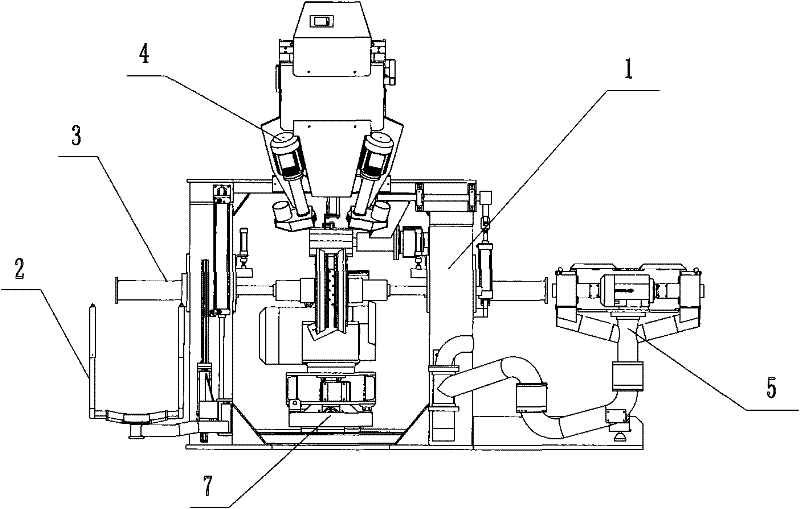

[0047] Example 1, such as Figure 1 to Figure 3 As shown, the fully automatic tire retreading machine using the sidewall grinding device 4 mainly has a main frame 1 .

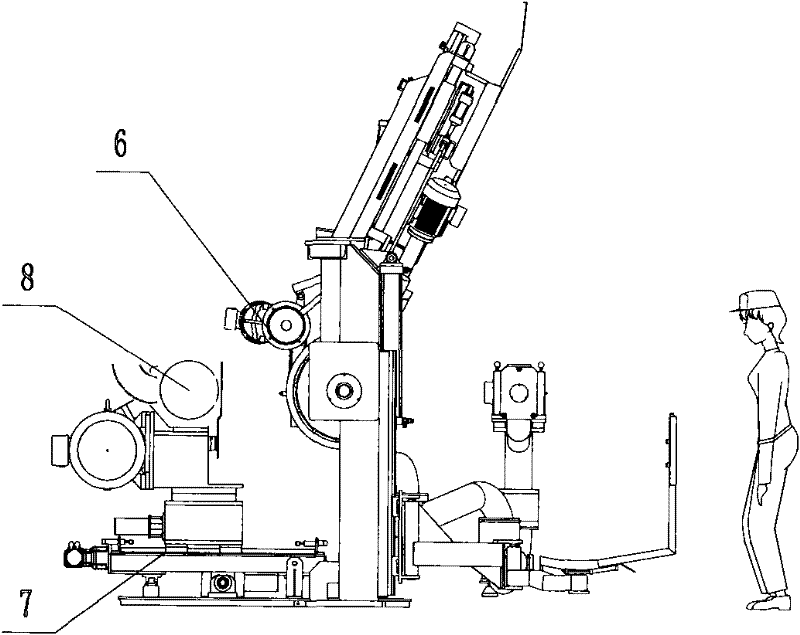

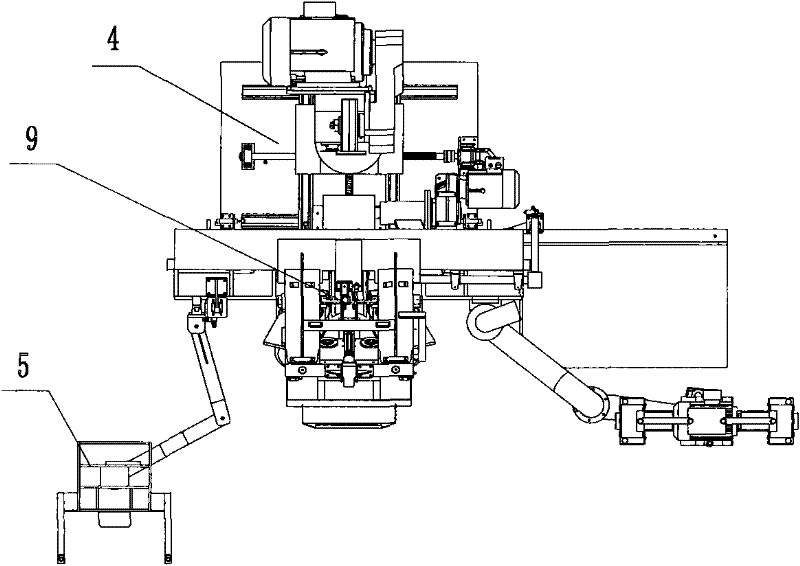

[0048] A lifting device 2, a driving device 6, a sliding device 7 and a thickness measuring device 9 are installed on the main frame 1, a grinding device 8 is rotatably connected to the sliding device 7, and a set of clamping devices are installed on both sides of the main frame 1 device 3.

[0049] Such as Figure 4 and Figure 5 As shown, the sidewall grinding device 4 is arranged on the top of the main frame 1 of the grinding machine. in,

[0050] The electric cylinder 41 is installed on the main frame 1, the driving rod of the electric cylinder 41 is connected to a carriage 42, and the carriage 42 is movably sleeved on a vertically arranged optical axis 46,

[0051] The tops of the two symmetrical slide plates 43 are respectively connected to the carriage 42 through a hinge shaft 432 . The bottom end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com