Patents

Literature

49results about How to "Realize the feeding function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

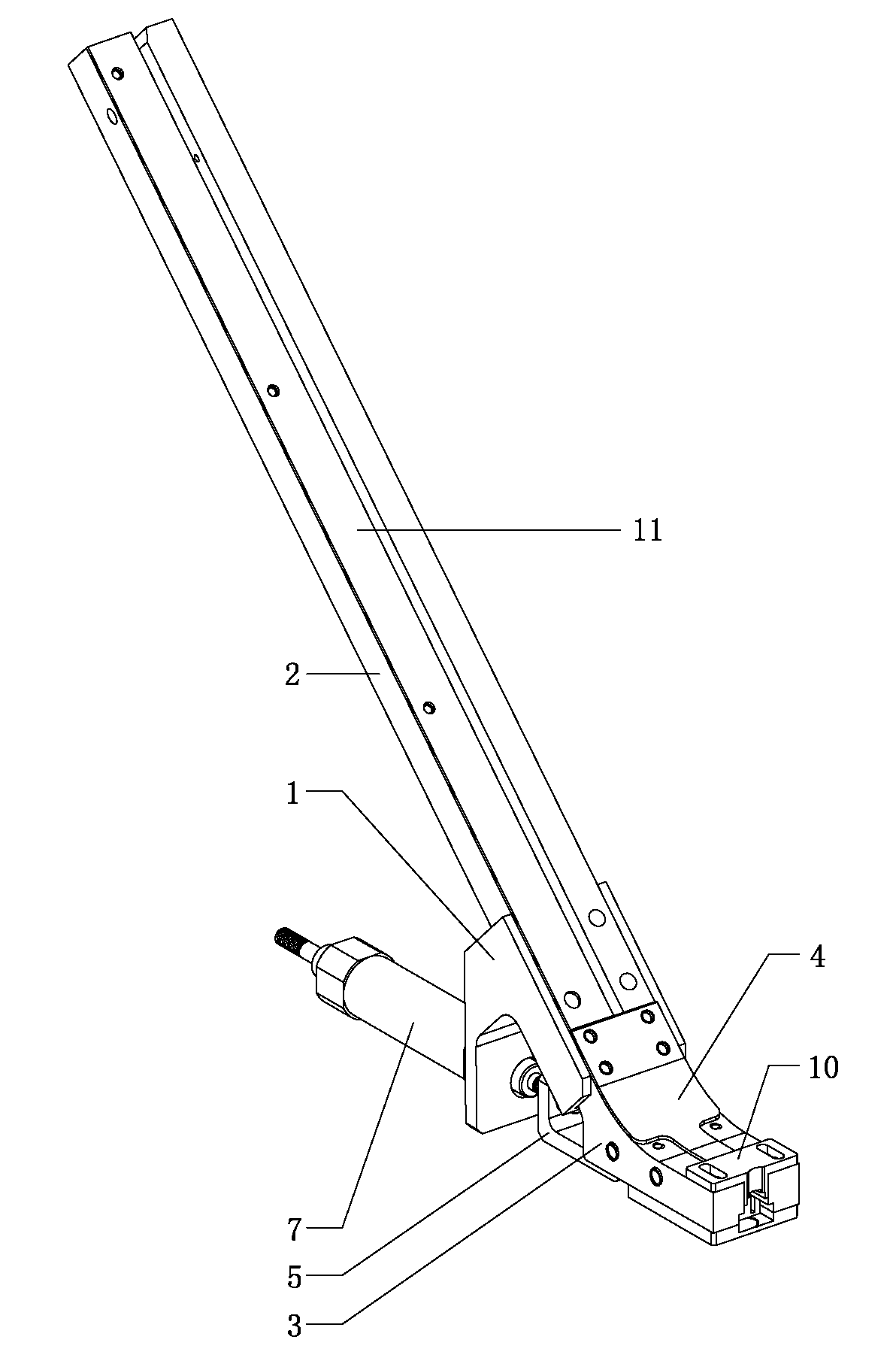

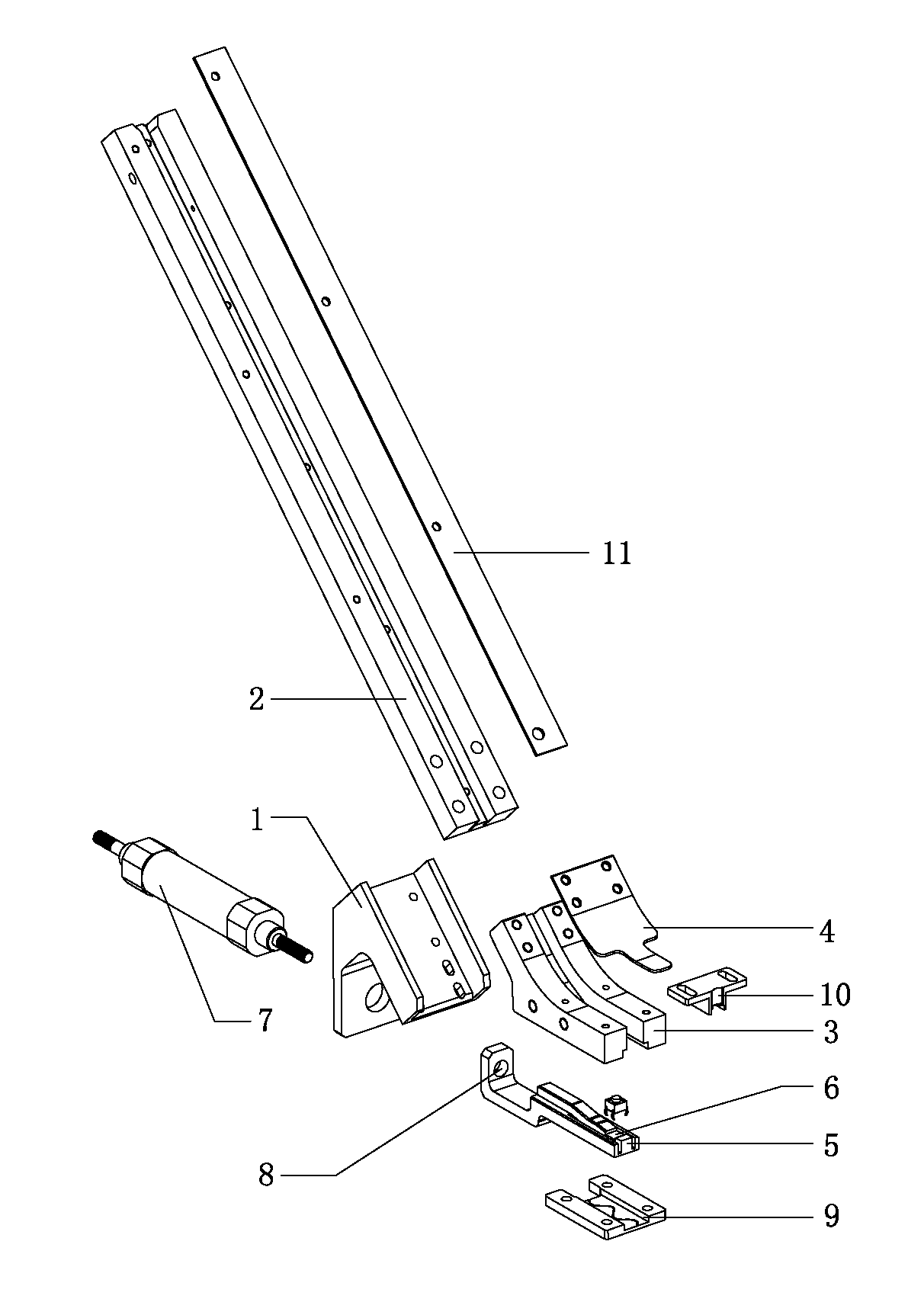

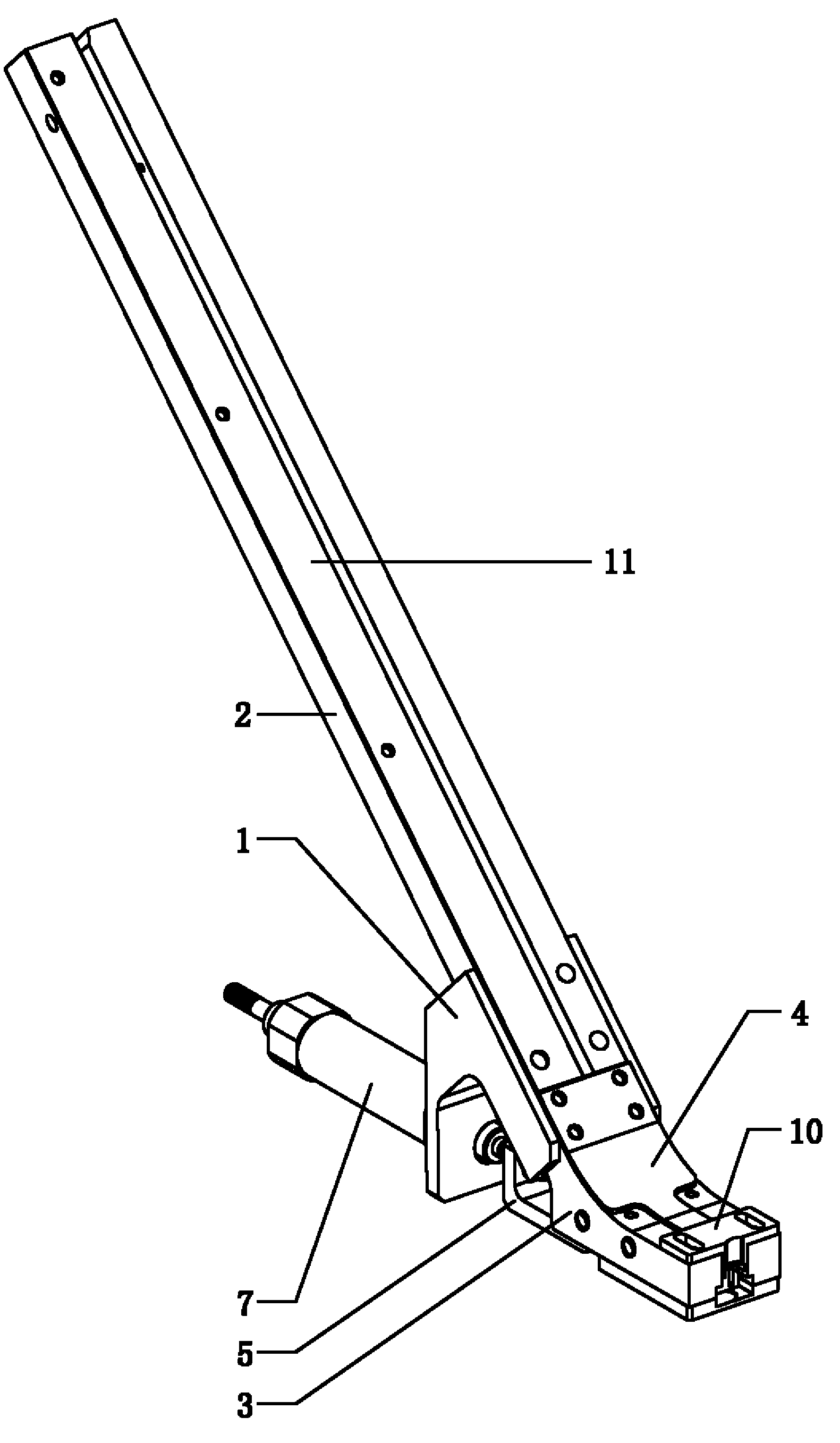

Improved type element feed mechanism

InactiveCN102118956AImprove accuracyReduce difficultyElectrical componentsMechanical engineeringPrinted circuit board

The invention relates to an improved type element feed mechanism relating to the technical field of electronic element insertion machines. The improved type element feed mechanism comprises a guide rail fixing seat, a long guide rail and a driving mechanism, wherein the long guide rail is arranged on the guide rail fixing seat; the bottom end part of the long guide rail is provided with an arc-shaped guide rail; the upper end part of the arc-shaped guide rail is butted with the lower end part of the long guide rail; a guide rail pressing strip is arranged above a guide slot of the arc-shaped guide rail; the lower part of the arc-shaped guide rail is provided with a movable feed slide block; the feed slide block is provided with a slot capable of containing only one electronic element; and the driving mechanism is used for driving the feed slide block to move back and forth. In the invention, the driving mechanism conveys only one electronic element to a specified position by operating one time so as to greatly enhance the clamping accuracy of a clamping device, reduce the difficulty in clamping work and enhance the feed efficiency of the insertion machines, therefore the production efficiency of a PCB (Printed Circuit Board) is enhanced; and in addition, the advantages of obvious progressiveness and high practicability are achieved.

Owner:DONGGUAN SCIENCGO MACHINERY MFG

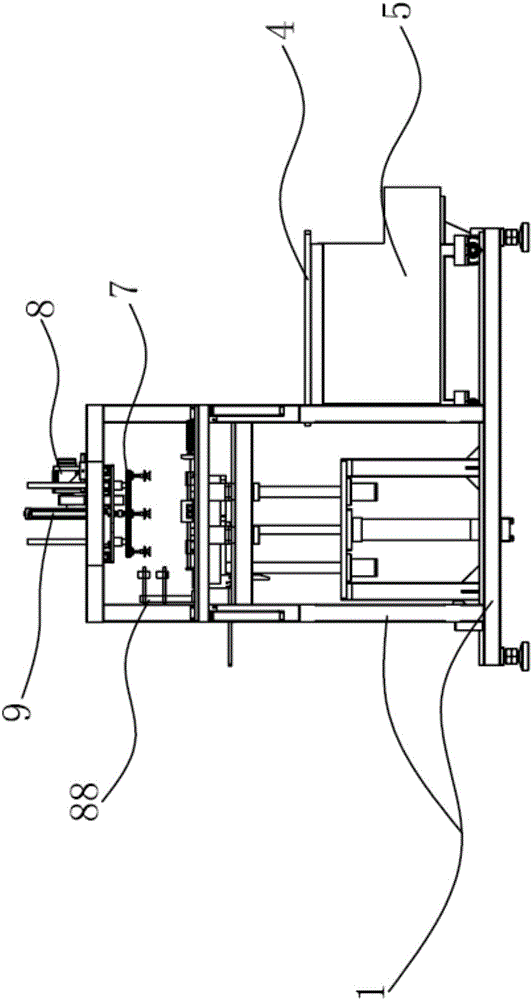

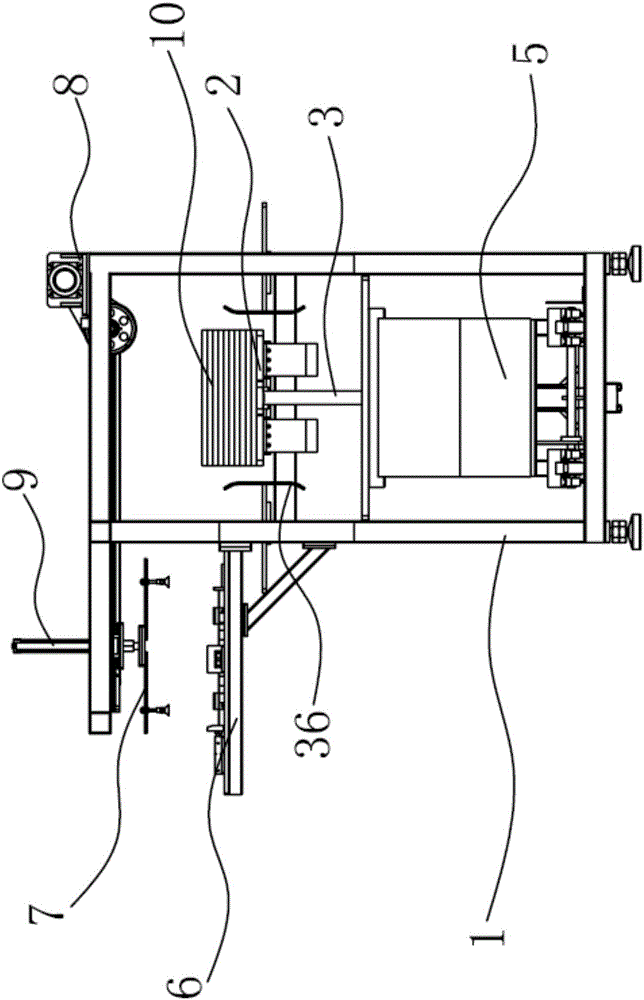

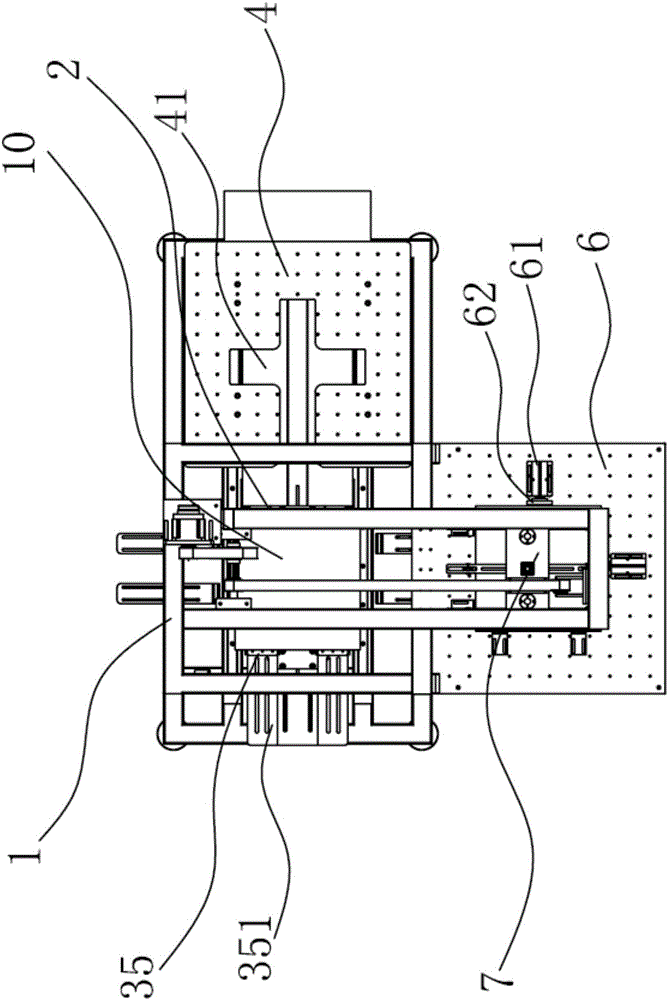

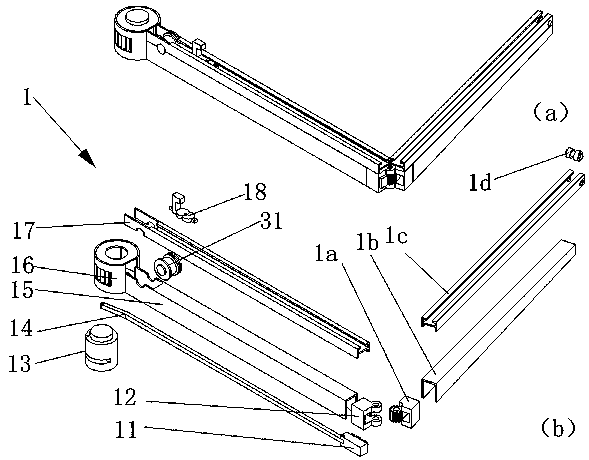

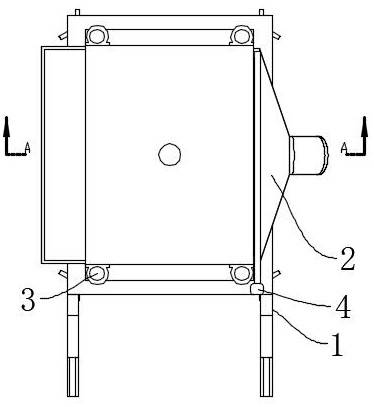

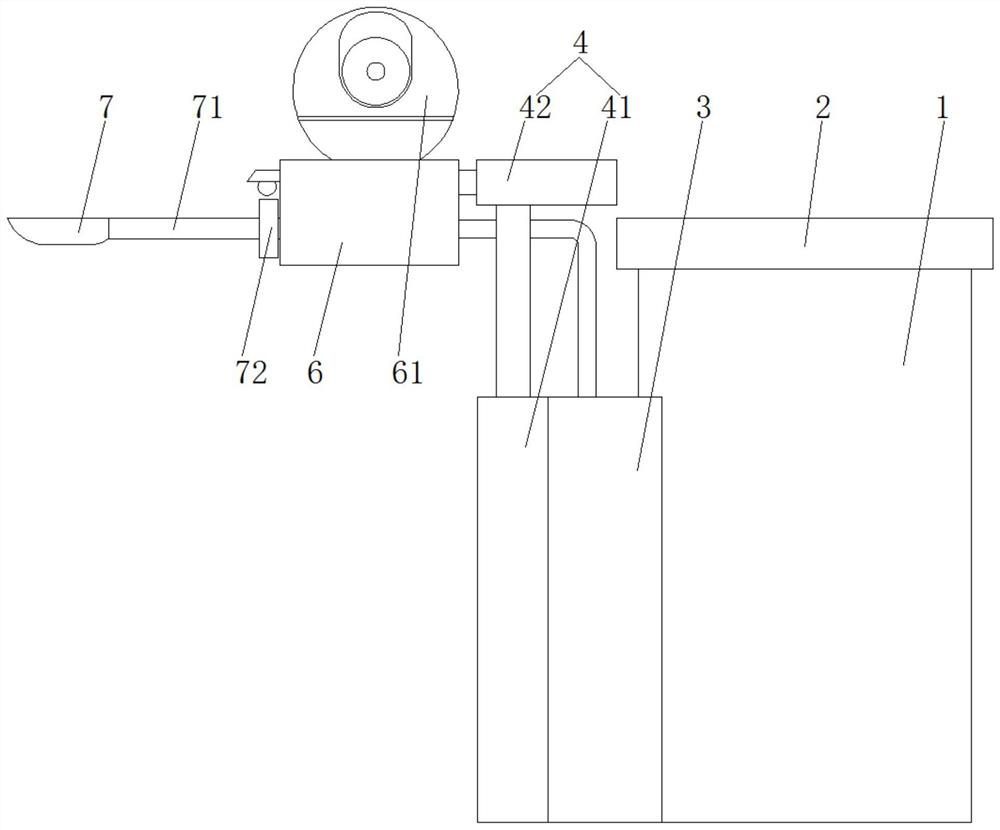

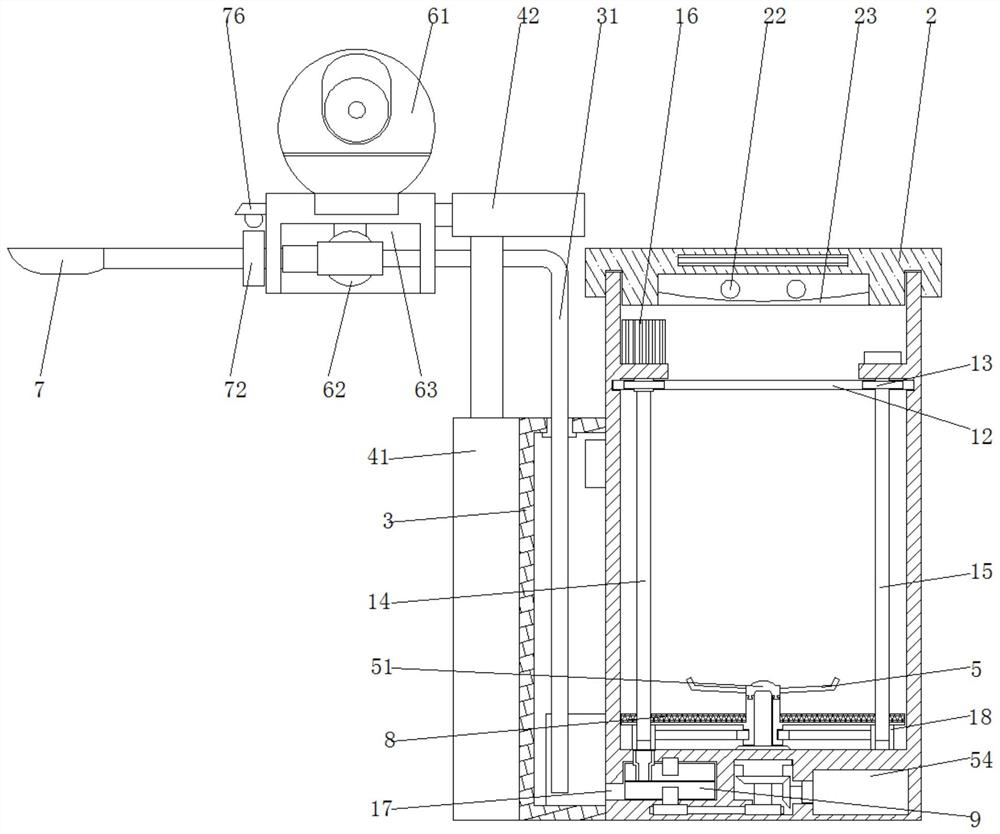

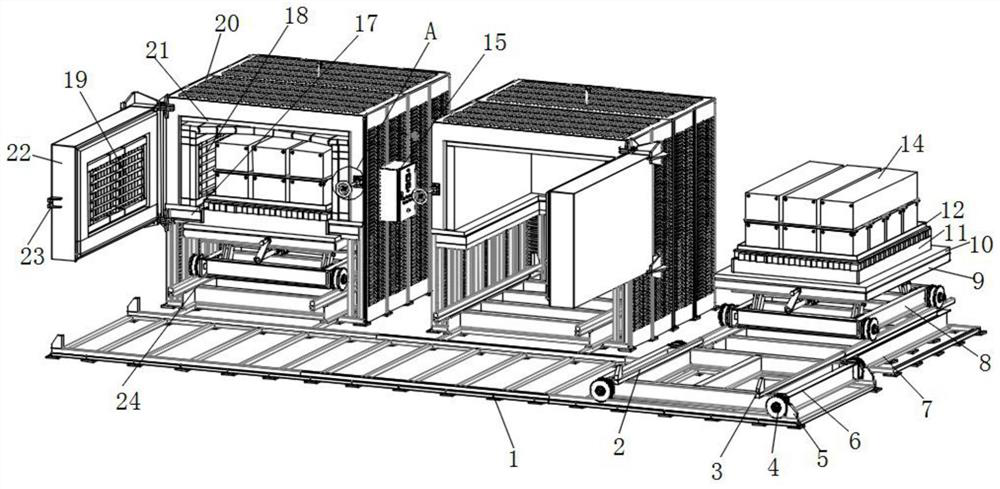

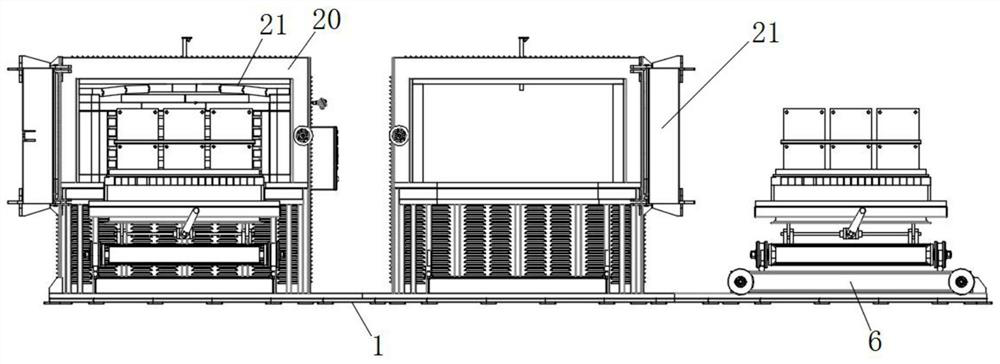

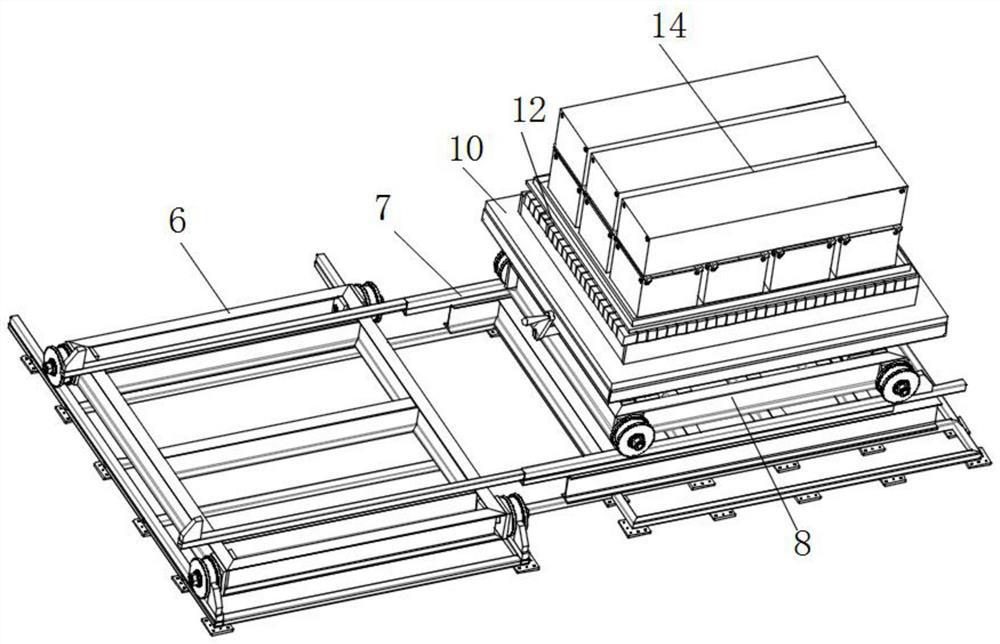

Feeding type single-station feeding material rack

InactiveCN105109960AFast and precise retrieving actionRealize the feeding functionConveyor partsRack unitMaterial supply

The invention discloses a feeding type single-station feeding material rack which comprises a machine base, a material rack unit, a conveying unit, a material supplying unit and a material taking unit. The material rack unit is driven by a first driving unit to move back and forth in the vertical direction. The conveying unit is arranged on one side of the material rack unit and is driven by a second driving unit to move back and forth in the horizontal direction, and products are ejected from bottom to top and horizontally moved to the material rack unit from the conveying unit. The material supplying unit is fixedly arranged on the machine base and located on the other side of the material rack unit. The material taking unit is fixedly arranged above the material rack unit and the material supplying unit and is driven by a third driving unit to move back and forth between the material rack unit and the material supplying unit in the horizontal direction. Meanwhile, the material taking unit is driven by a fourth driving unit to move back and forth in the vertical direction. According to the feeding type single-station feeding material rack, the products can be accurately located and fast taken through a mechanical arm, and under the conditions that the material taking success rate is guaranteed and the products are not damaged, the production efficiency of the whole material rack and a production line can be improved.

Owner:YIHE PRECISION IND SUZHOU

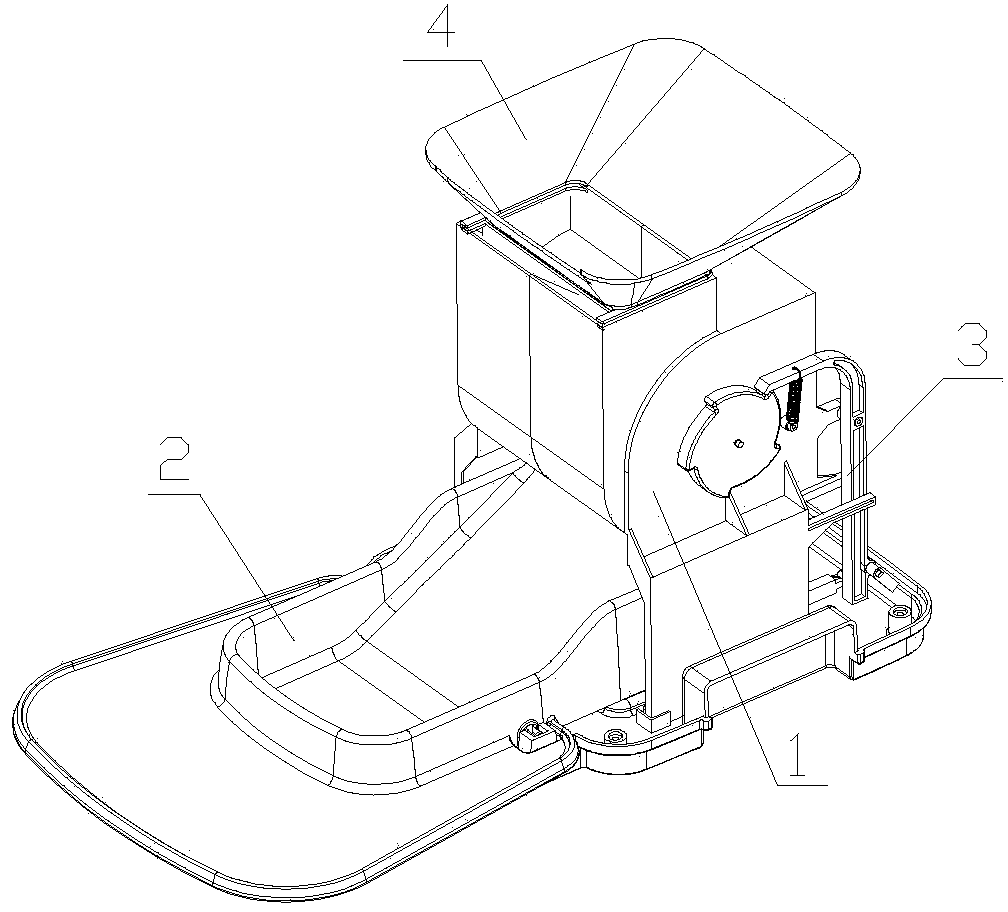

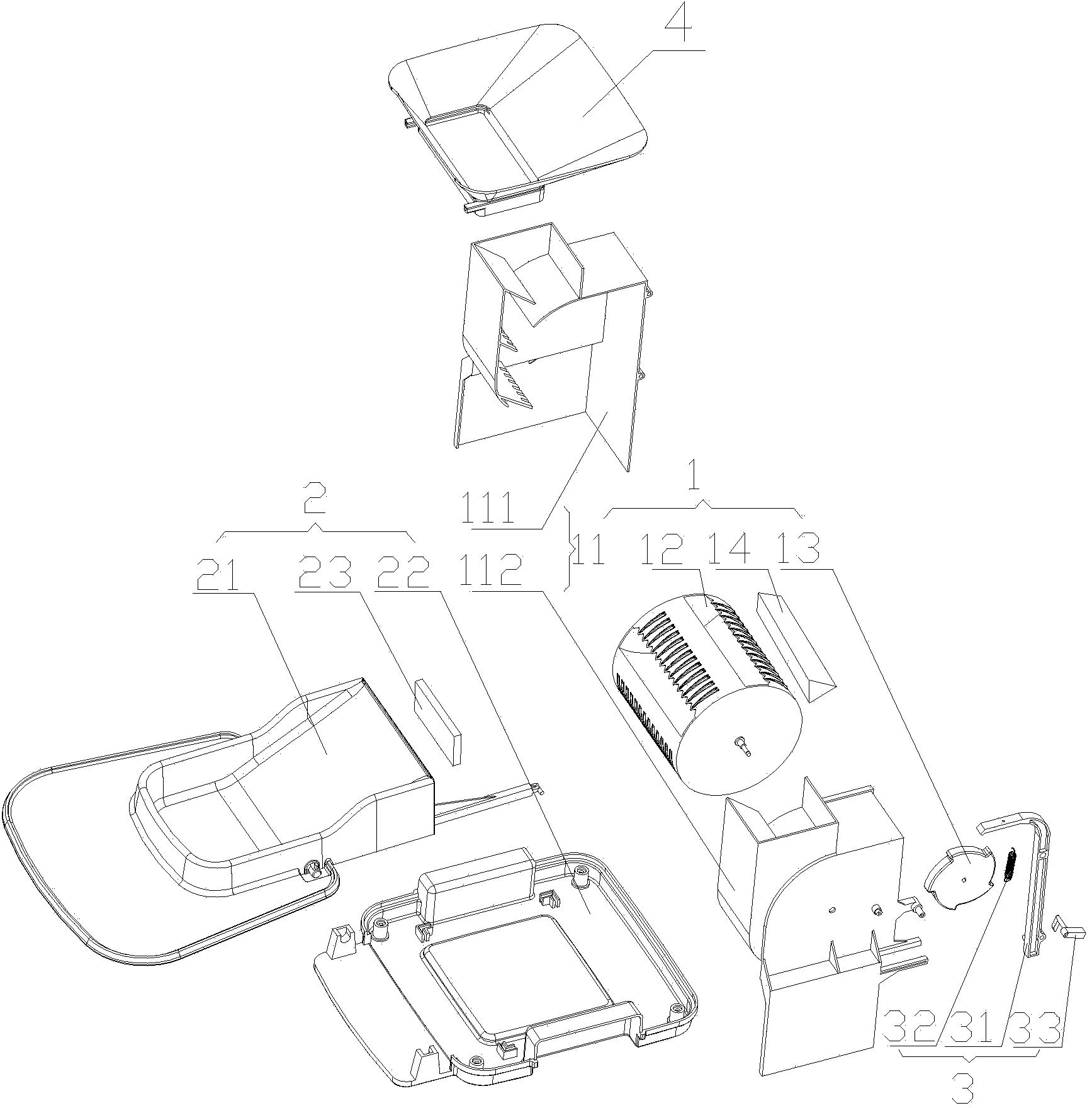

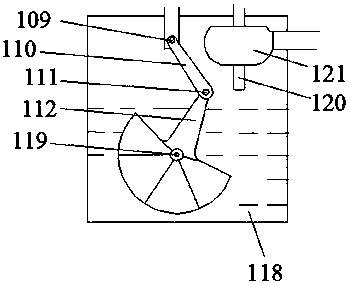

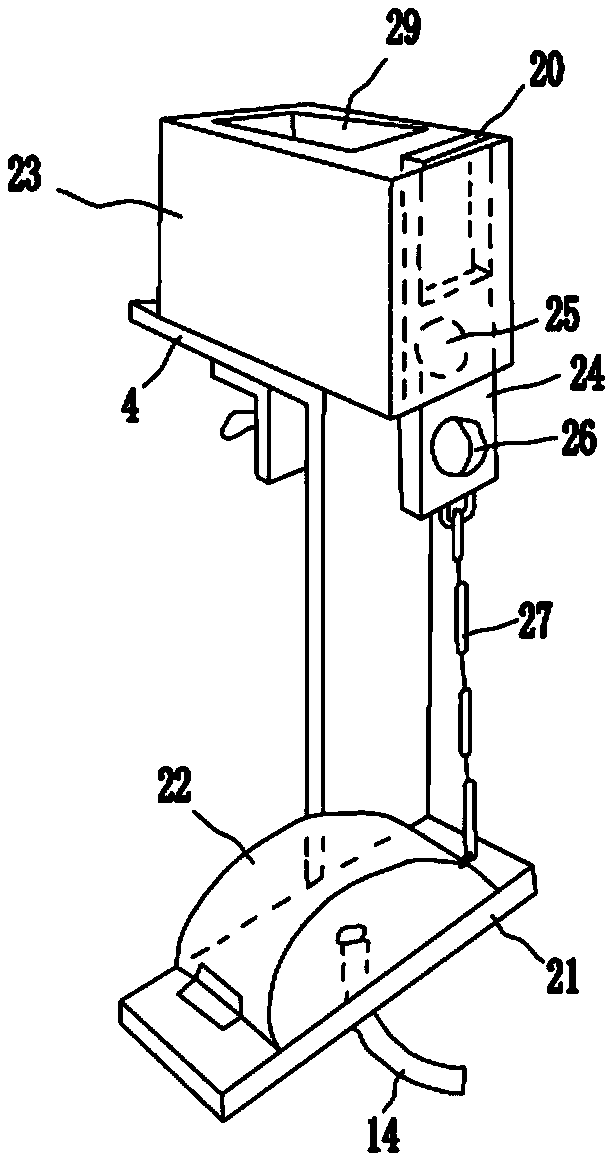

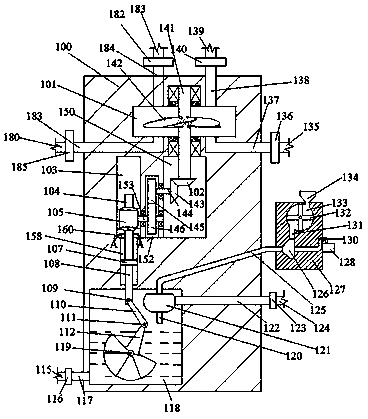

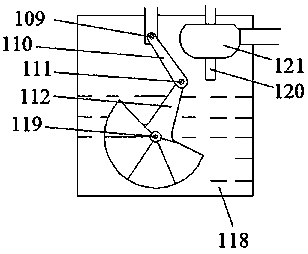

Foot step type pet self-service feeder

ActiveCN104365498AImprove learning effectImprove survivabilityAnimal feeding devicesAvicultureFood guideEngineering

The invention discloses a foot step type pet self-service feeder which comprises a food guide mechanism, a lever mechanism, a brake mechanism and a food storage mechanism. The lever mechanism is arranged below the food guide mechanism, the lower end of the food storage mechanism is open, and the opening of the food storage mechanism is eccentrically formed over the food guide mechanism; the brake mechanism is connected with the lever mechanism and the food guide mechanism; the lever mechanism comprises a pedal and a base supporting the pedal, and the pedal can rotate around the base. After a pet steps down the pedal, the other end of the pedal cocks, limiting of the brake mechanism on the food guide mechanism is relieved, the food guide mechanism rotates, and pet food enters the food guide mechanism from the food storage mechanism and falls down from the food guide mechanism when the food guide mechanism rotates. After the pet steps on the pedal, the serial subsequent mechanical linkage movements of the foot step type pet self-service feeder enable the pet food to enter a feeding box automatically from a hopper, and therefore a feeding function is achieved; in addition, the function can be achieved through the pet itself, the learning capacity and the capacity for obtaining the food of the pet can be improved beneficially, and meanwhile the survival capacity of the pet is improved.

Owner:ZHUHAI HENGQIN SUPER TECH LTD

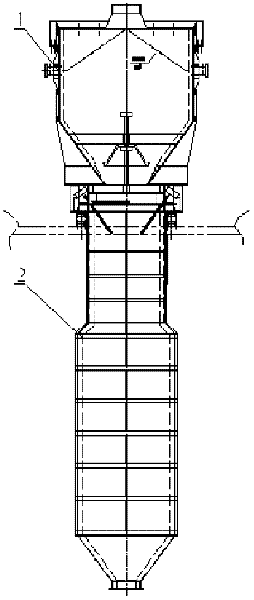

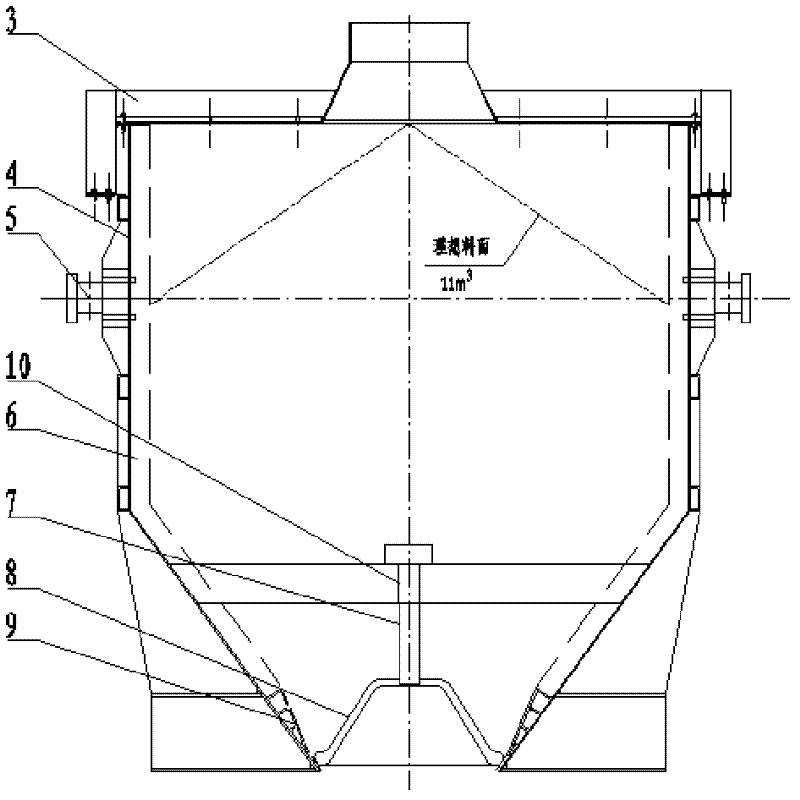

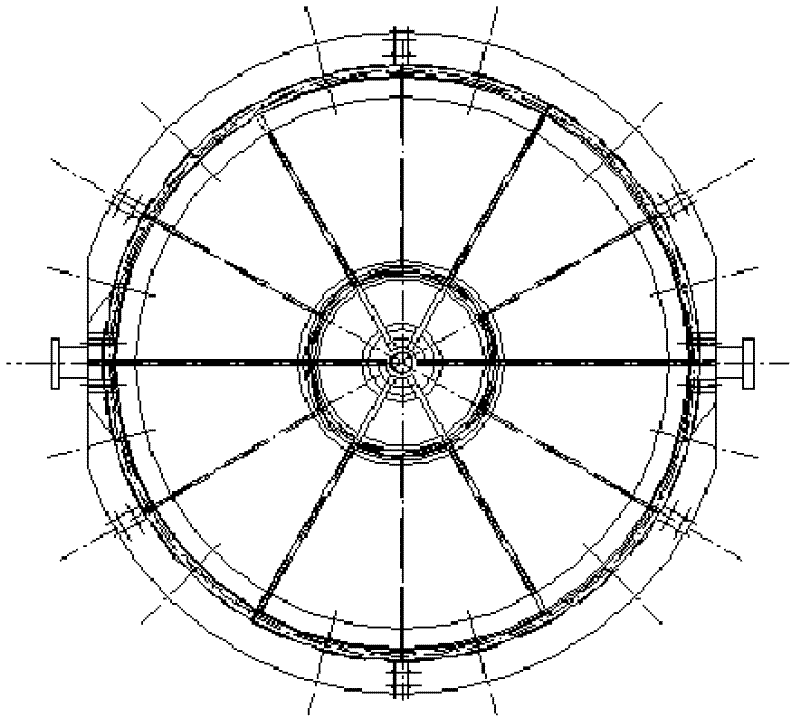

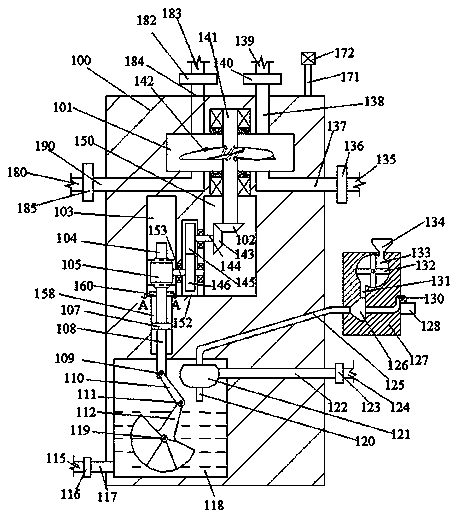

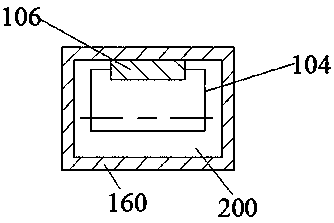

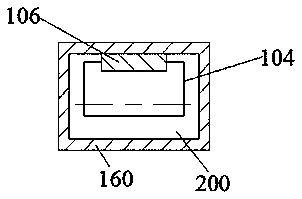

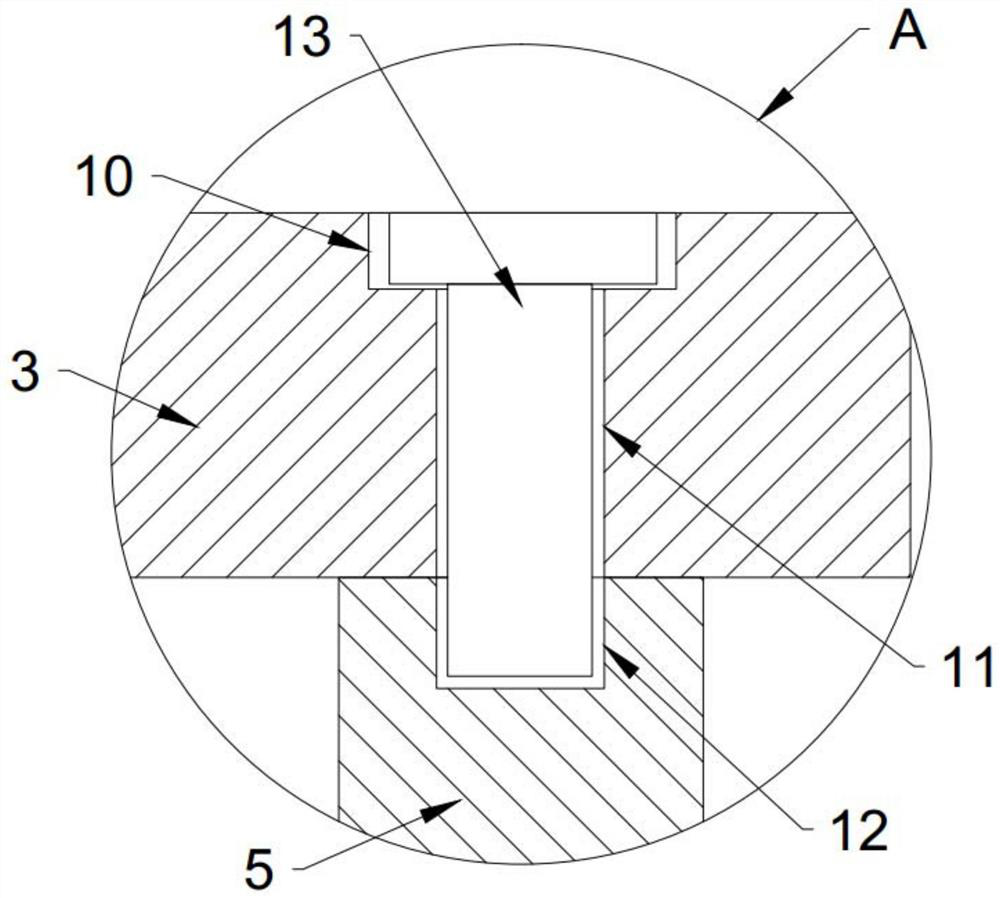

Hot aggregate bin capable of automatically receiving and feeding materials and hot aggregate tank matched with hot aggregate bin

ActiveCN102374786ARealize the feeding functionRealize the receiving functionCharge manipulationEngineeringEnergy conservation

The invention discloses a hot aggregate bin capable of automatically receiving and feeding materials and a hot aggregate tank matched with the hot aggregate bin. The hot aggregate bin comprises an upper upright pole, an upper tank pressure-bearing platform, a balance weight automatic bin cover mechanism, a dustproof cover, a weighing module and a bin body. The hot aggregate tank matched with the hot aggregate bin comprises an insulation type tank cover, a hot aggregate tank body, a lug shaft, a guide pole, a bottom seal inverted bell and a bottom insulation steel cone structure. Because the bottom seal inverted bell and the guide pole of the hot aggregate tank can be matched with the upper upright pole and the upper tank pressure-bearing platform of the hot aggregate bin for opening the bottom of the hot aggregate tank for realizing a feeding function; meanwhile, after the feeding action is generated, the balance weight automatic bin cover mechanism can be opened under the gravity of the fed materials for realizing the receiving function. The whole feeding and receiving action is continuous, when hot materials in the hot aggregate tank are fed completely, the hot aggregate tank isempty, and the balance weight automatic bin cover mechanism of the hot aggregate is automatically opened, so that the automatic integration of feeding and receiving actions are realized. The invention has the advantages of high production efficiency, energy saving and no dust raising.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

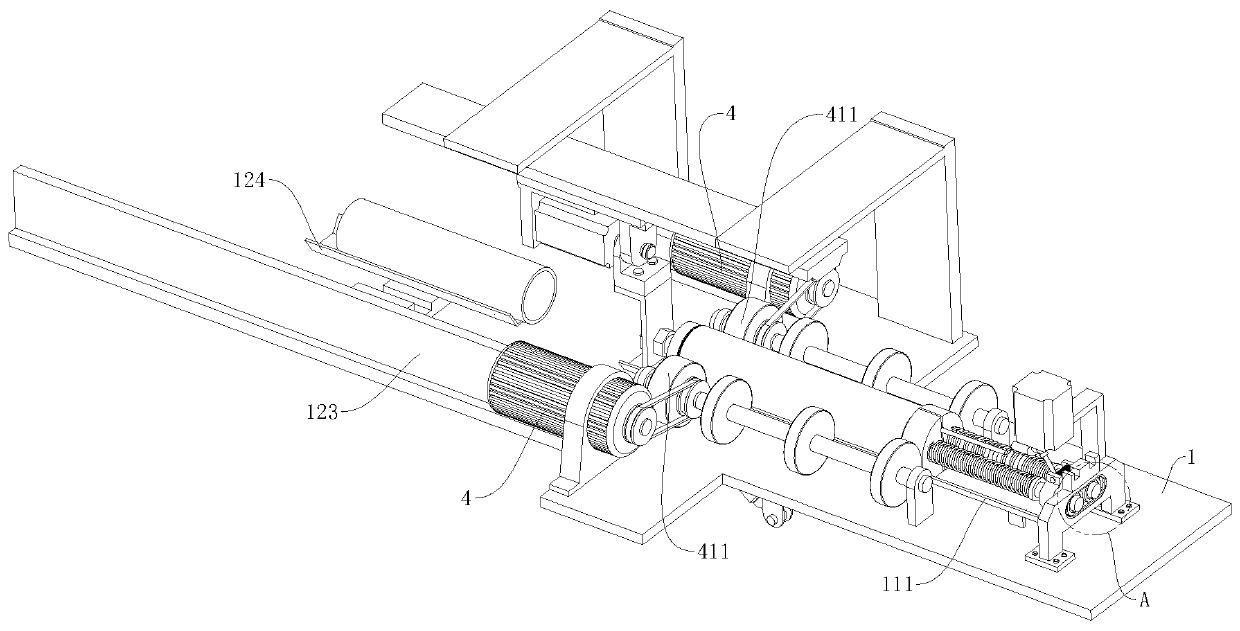

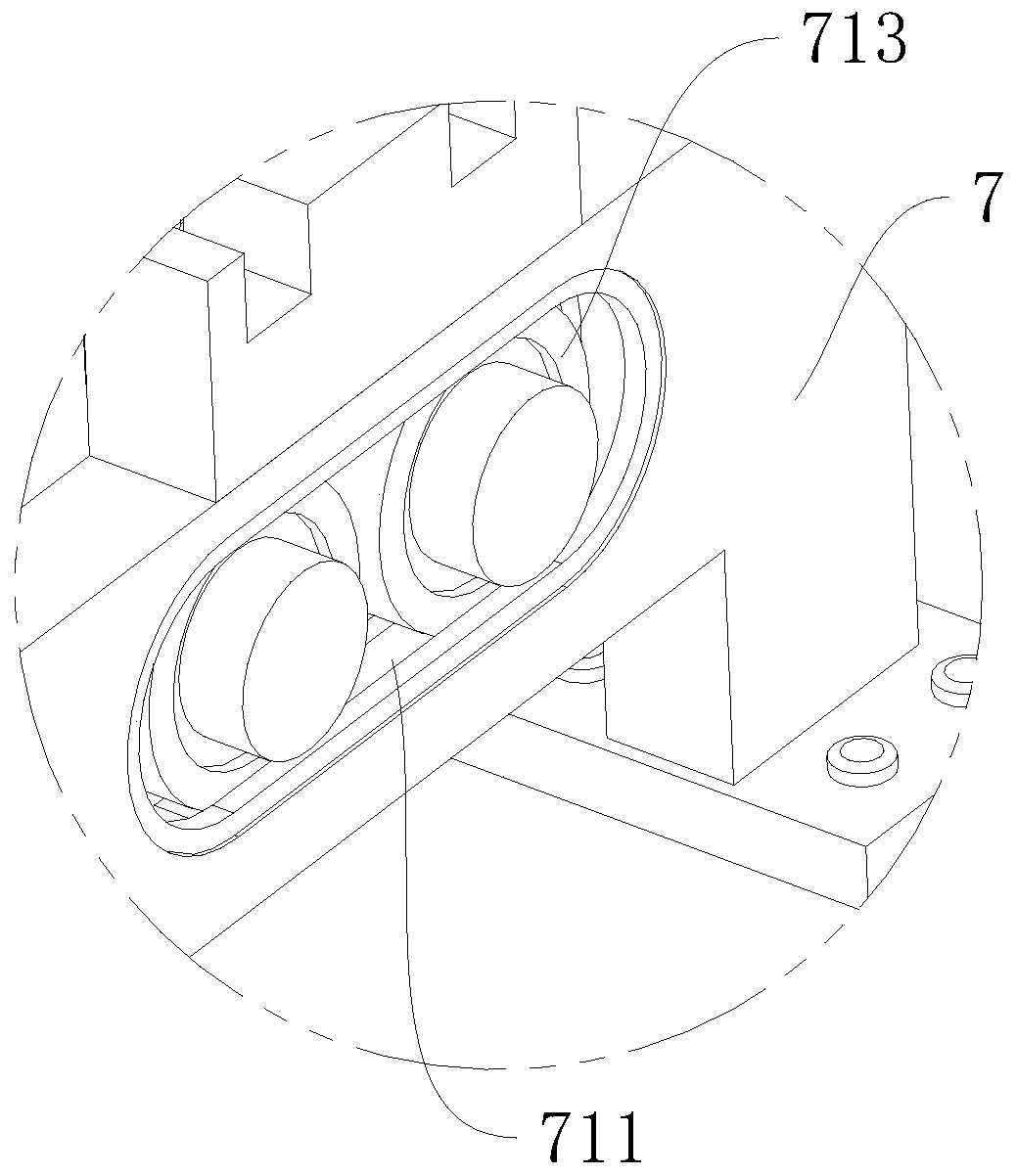

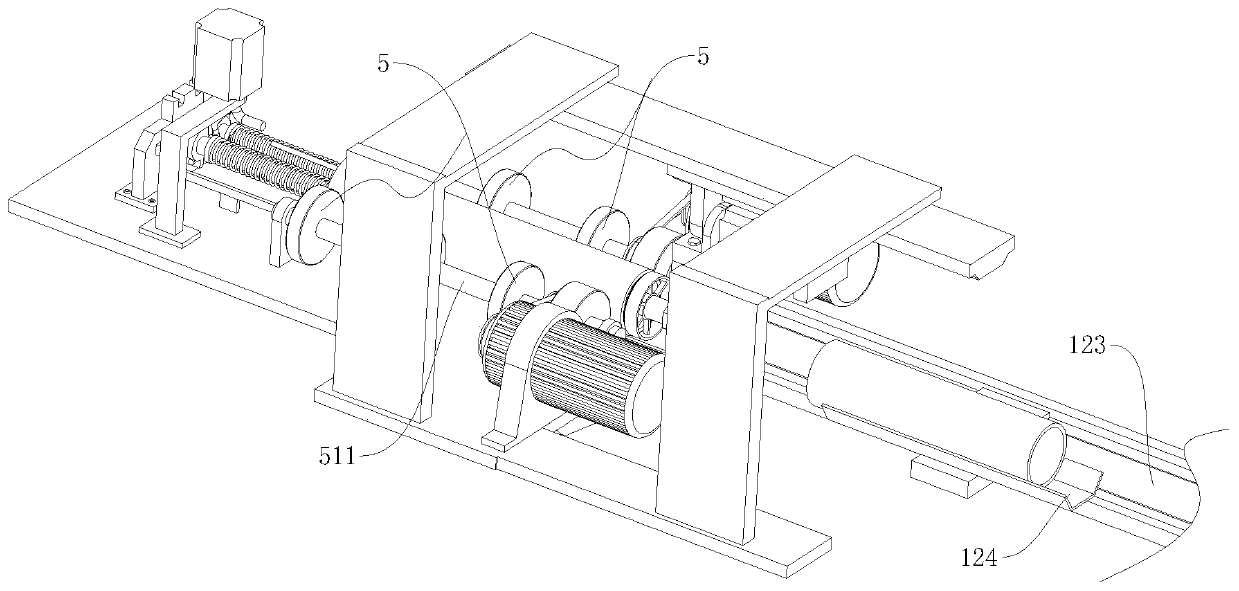

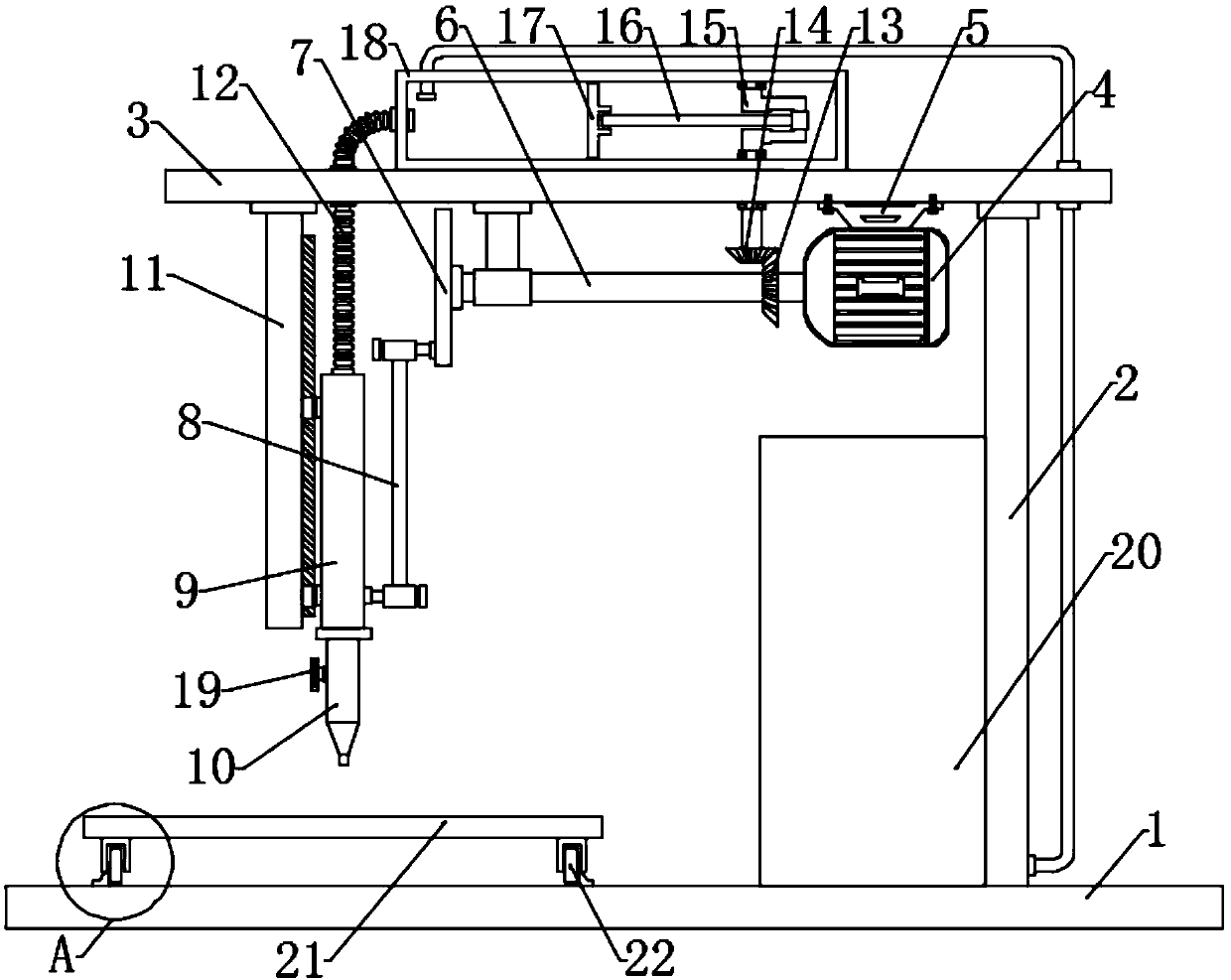

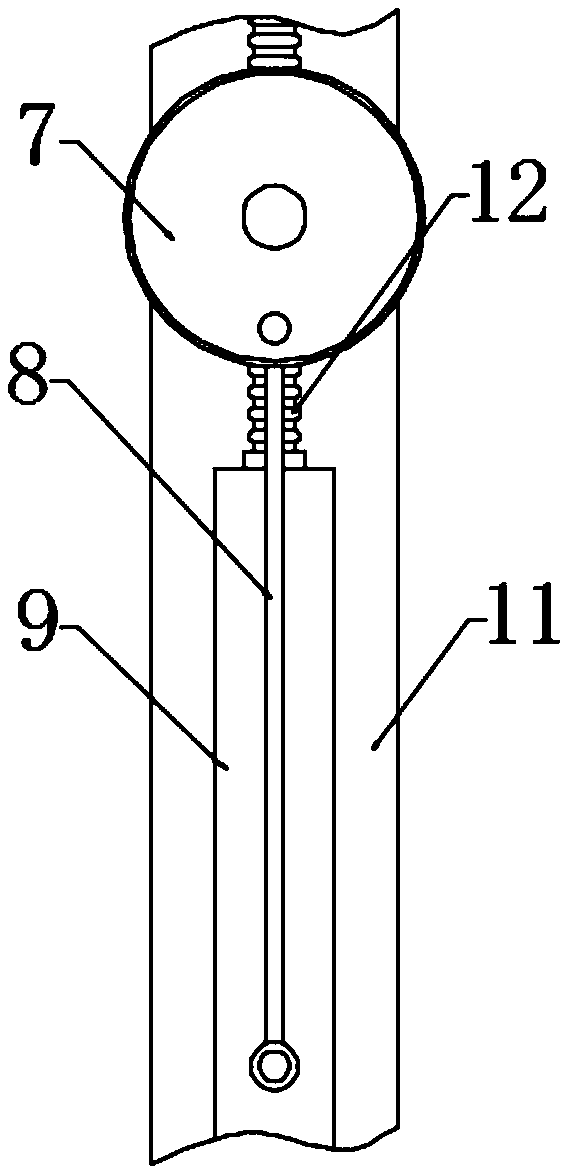

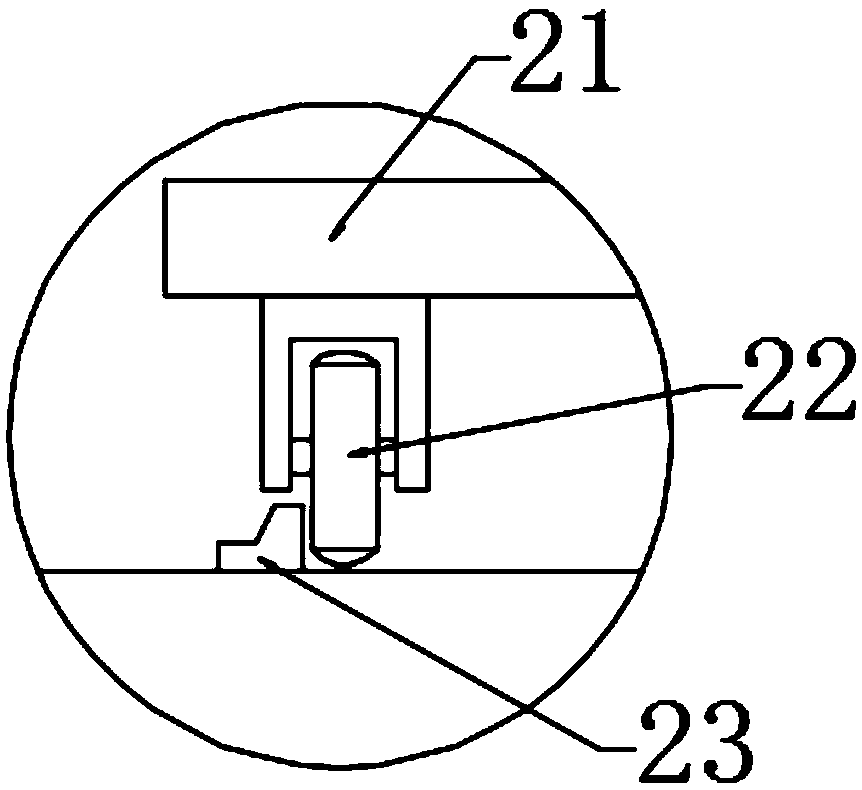

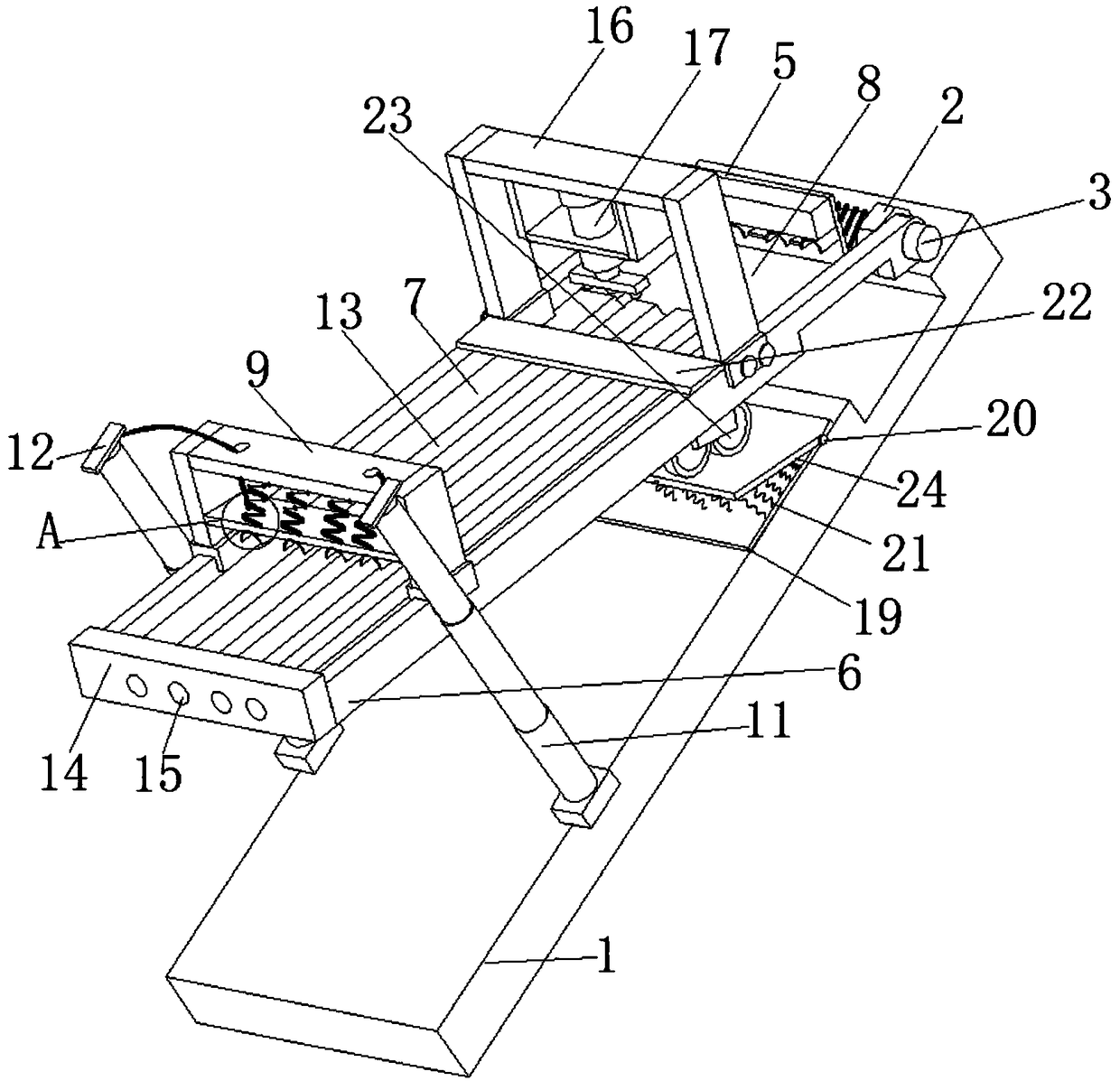

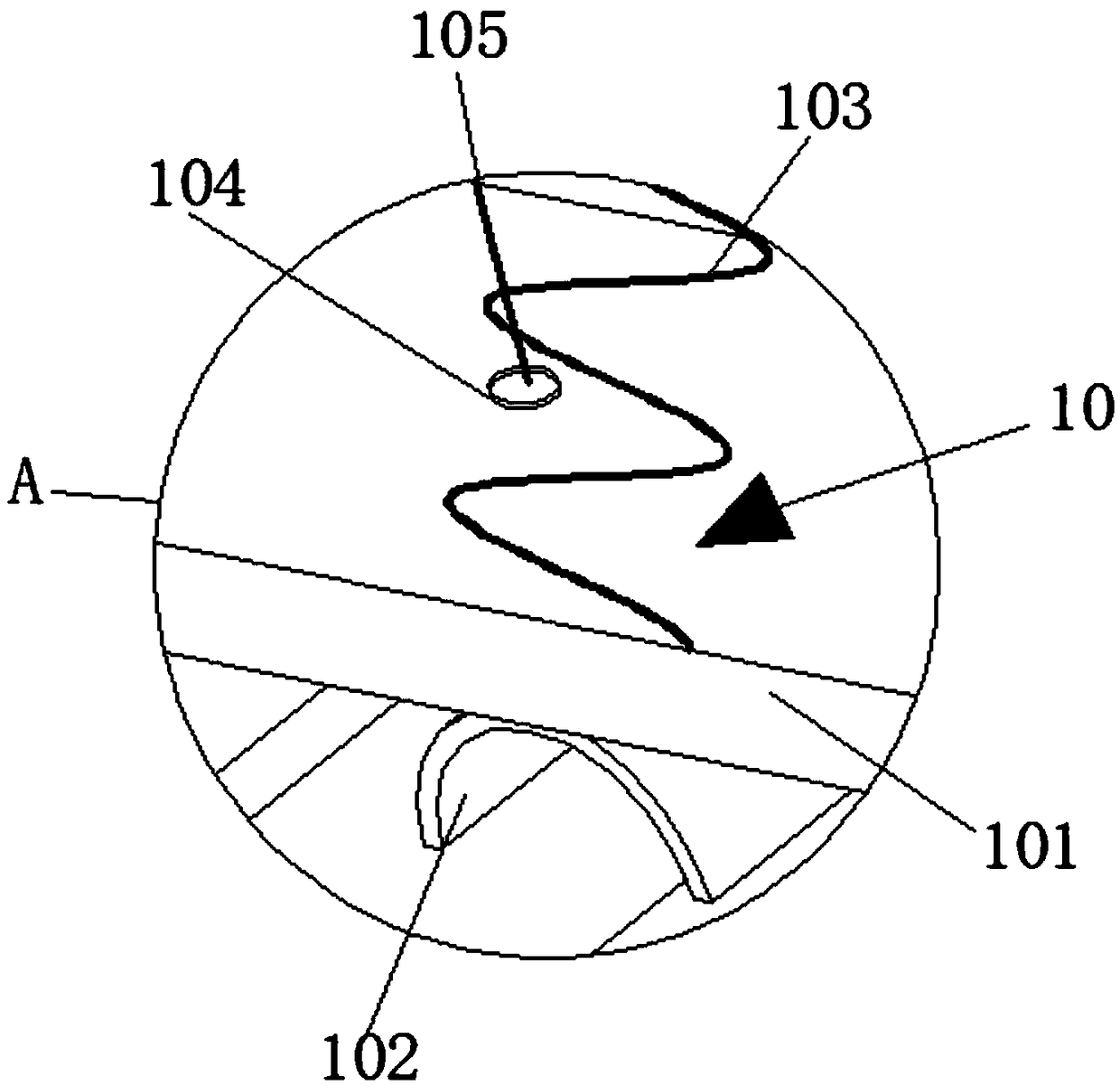

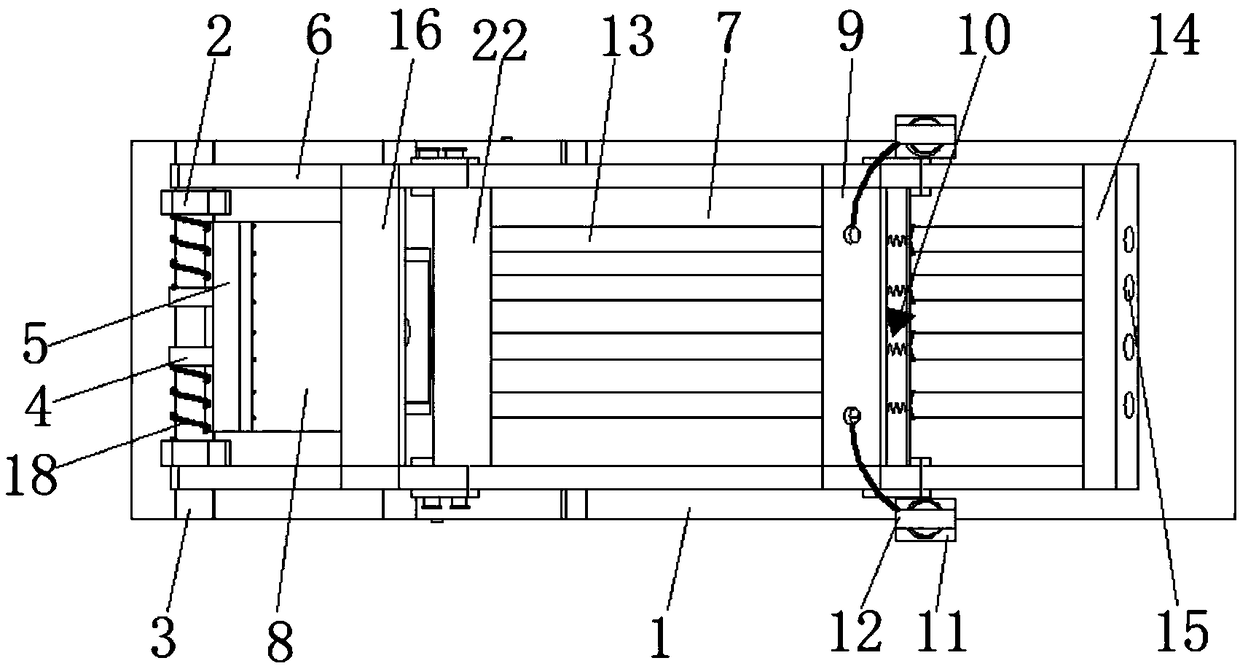

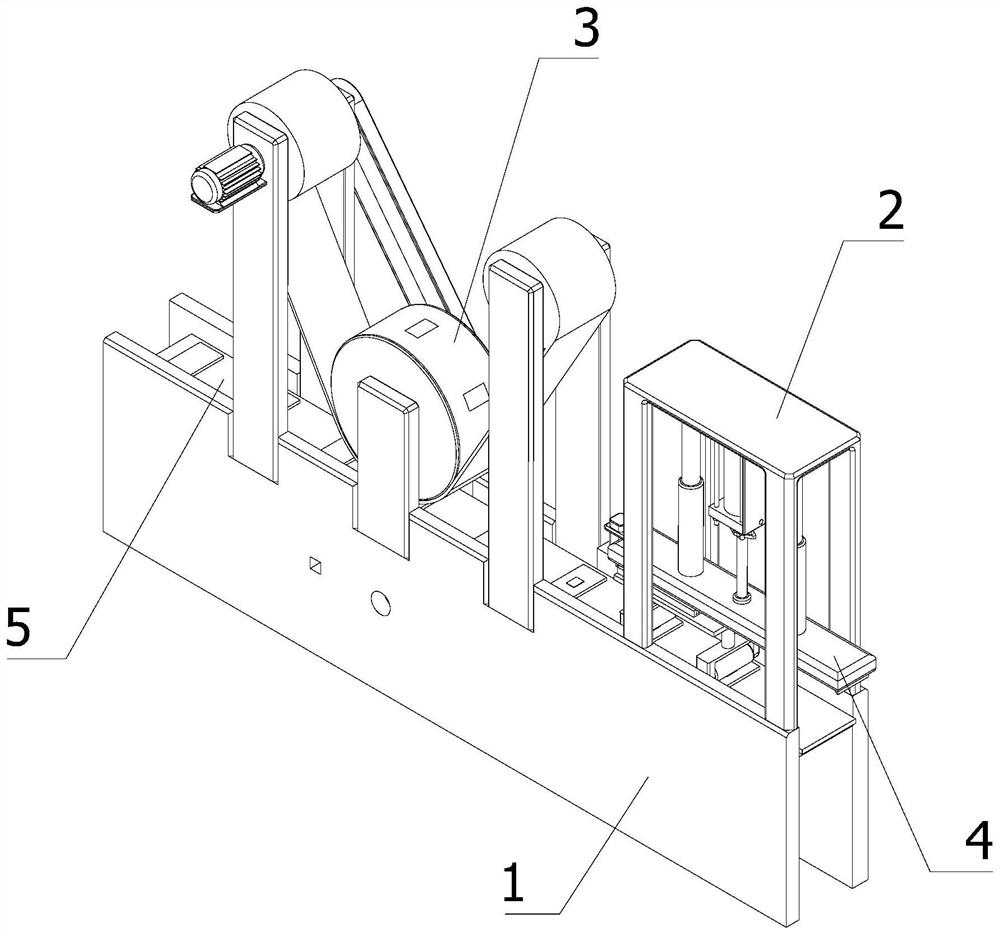

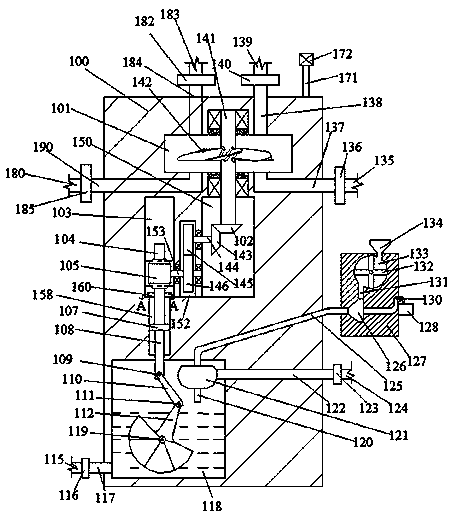

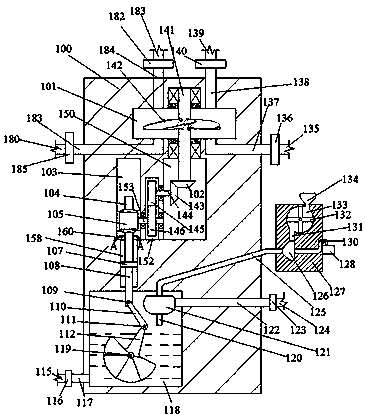

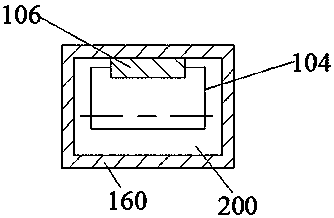

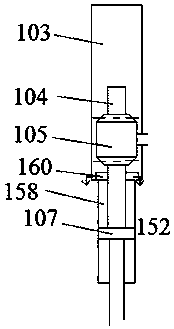

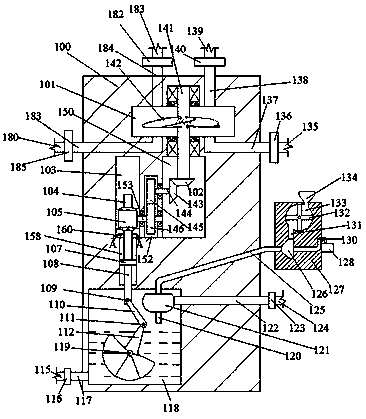

Automatic machining equipment for embossing roller shaft

InactiveCN110405550APropulsion sustained propulsionRealize the feeding functionRevolution surface grinding machinesGrinding drivesEngineeringContact mechanism

The invention relates to the field of embossing roller shaft machining, in particular to automatic machining equipment for an embossing roller shaft. The equipment comprises a machining table; and themachining equipment comprises a machining track, a contact mechanism, two outer circle grinding mechanisms and two inner circle grinding mechanism, wherein the machining track is horizontally arranged on the machining table, the two outer circle grinding mechanisms are arranged on the outside of one side of the machining track, a propelling electric cylinder is arranged above the machining track,a rotating mechanism is arranged on an output sliding block of the propelling electric cylinder, the contact mechanism is in transmission connection with the rotating mechanism, the end, facing the contact mechanism, of the machining track is an upstream end, a supporting device is arranged at a downstream end of the machining track, the two inner circle grinding mechanisms are symmetrically arranged between the two outer circle grinding mechanisms and are connected with the supporting device through a micro-motion adjuster, a discharging device is further arranged between the supporting device and each inner circle grinding mechanism, and the discharging devices can movably sleeve the micro-motion adjuster. According to the equipment, the inner and outer surfaces of the embossing rollershaft can be ground simultaneously, so that the machining efficiency is greatly improved.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

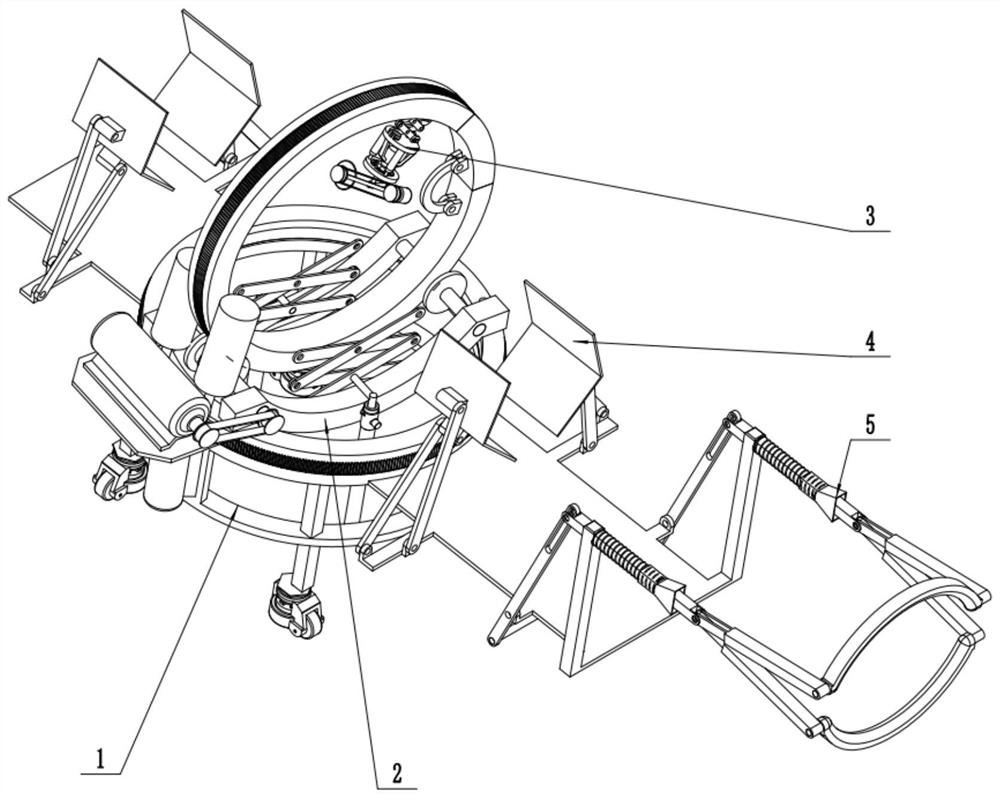

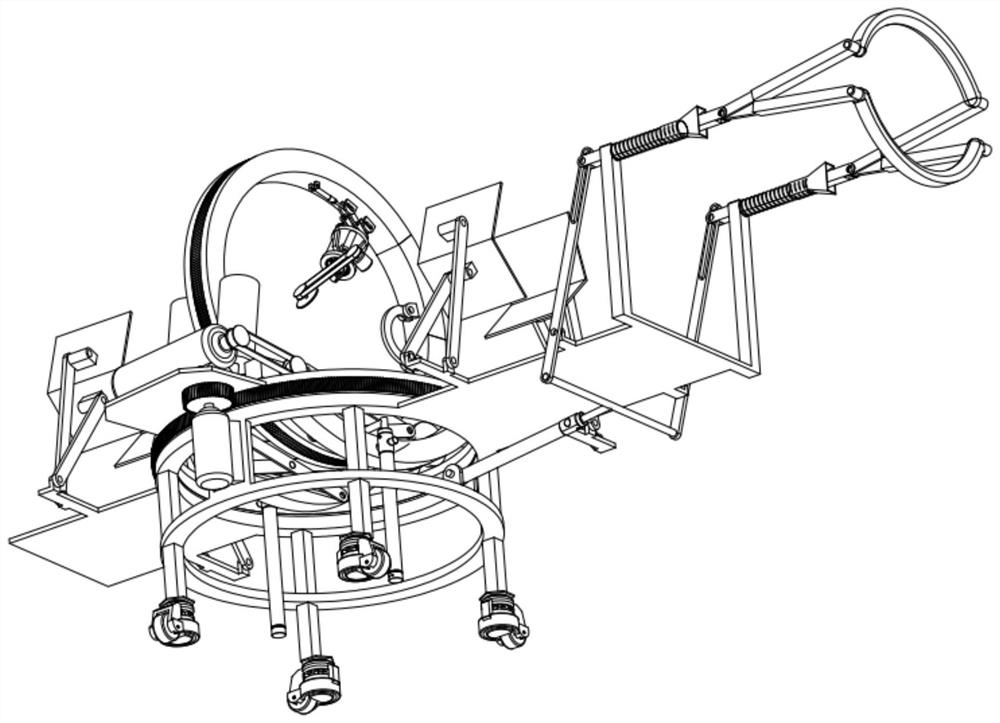

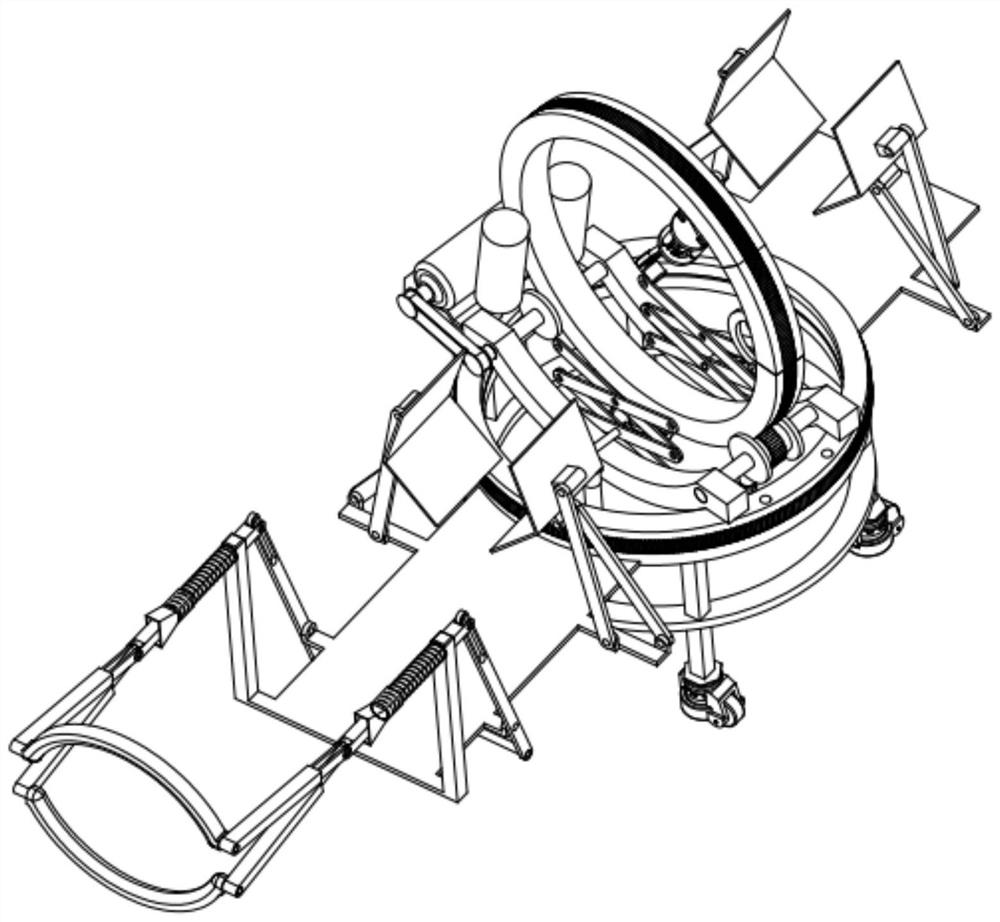

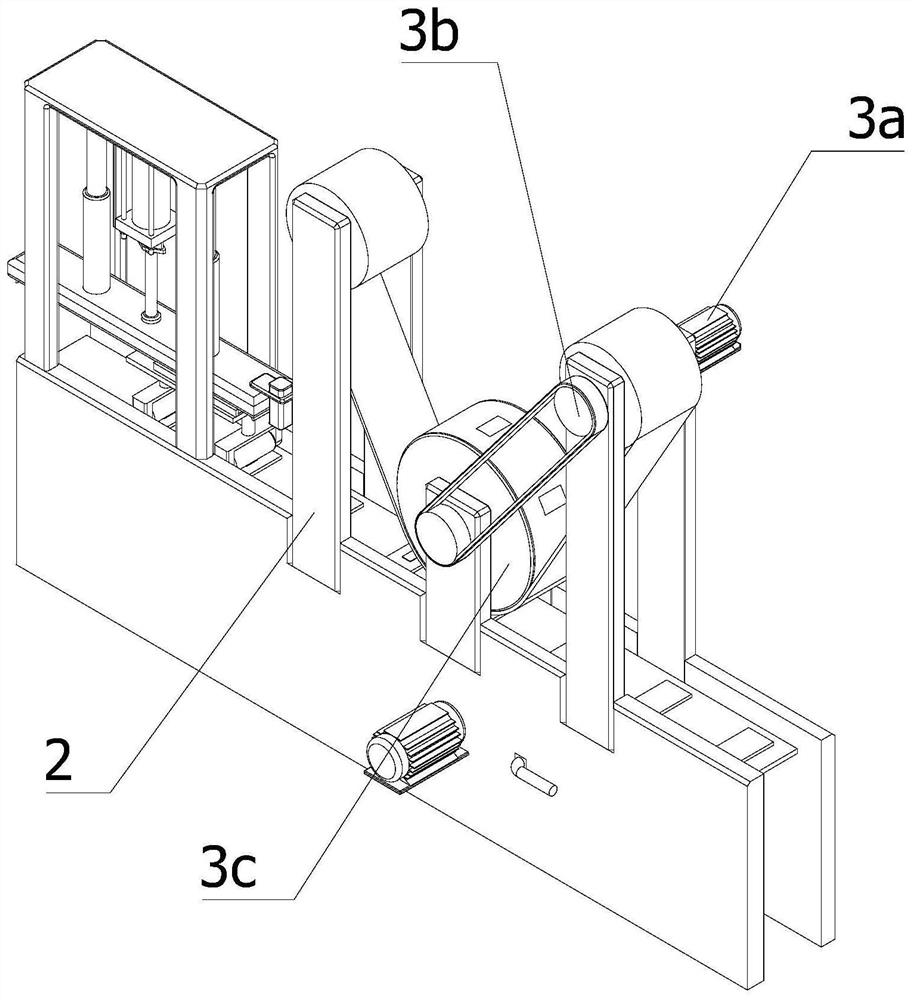

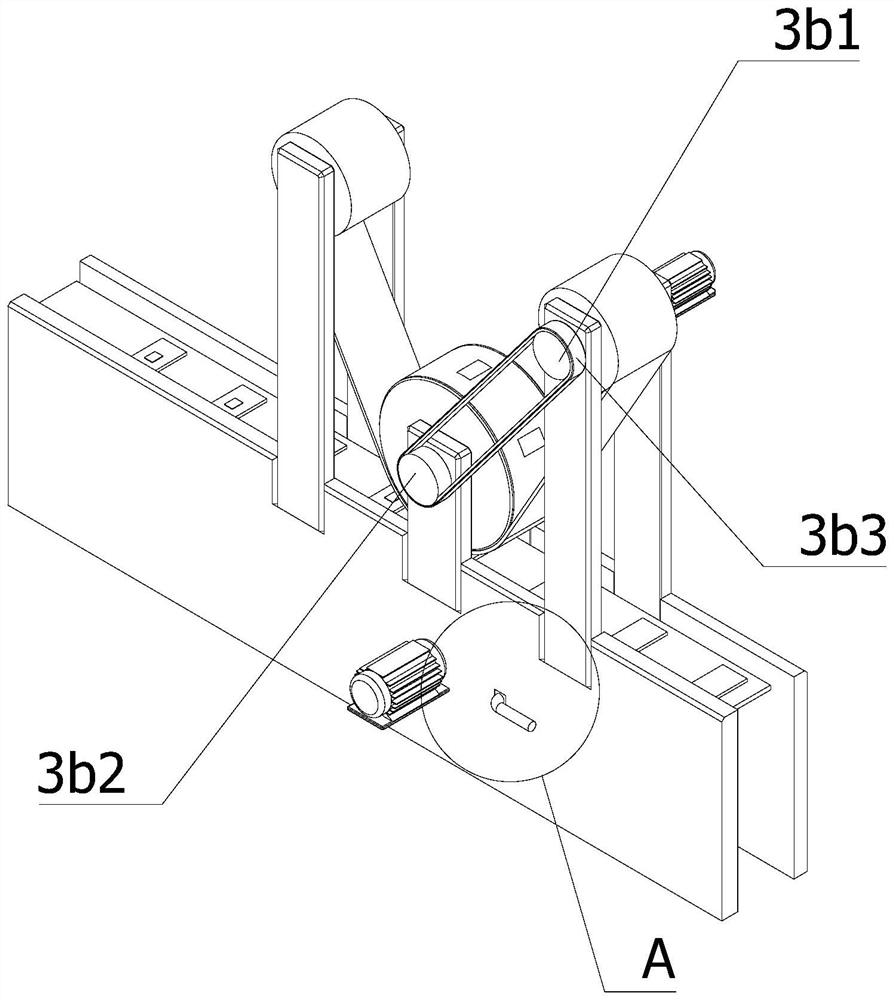

Large-diameter pipe cutting equipment

InactiveCN113458484AAchieve continuous tightening functionAchieve secondary clamping and fixingWorking accessoriesTube shearing machinesPhysicsElectric machinery

The invention discloses large-diameter pipe cutting equipment which comprises a support mechanism, a rotating mechanism, a cutting mechanism, a gravity clamping mechanism and a fixed feeding mechanism, wherein the support mechanism comprises a rack, a rotating motor and trundles; the rotating mechanism comprises a transverse rotating part, a supporting part and a longitudinal rotating part; the transverse rotating part is rotationally mounted on the upper end face of the rack; the supporting part is mounted on the upper end face of the transverse rotating part; the longitudinal rotating part is fixedly mounted on the upper end face of the transverse rotating part; the cutting mechanism is rotationally mounted on a support on the inner side of a longitudinal rotating part of the rotating mechanism; the gravity clamping mechanism is rotationally mounted on a support on the upper end face of the rack; the gravity clamping mechanism is extruded through the gravity of a pipe, then the gravity clamping mechanism tightly holds the pipe, so that it is guaranteed that the position of the pipe is stable; the fixed feeding mechanism is rotationally mounted on the support of the rack; and power of the cutting motor is transmitted through a cutting belt wheel set so as to drive a cutting tool bit is driven to rotate, so that rapid cutting is achieved.

Owner:苏涛

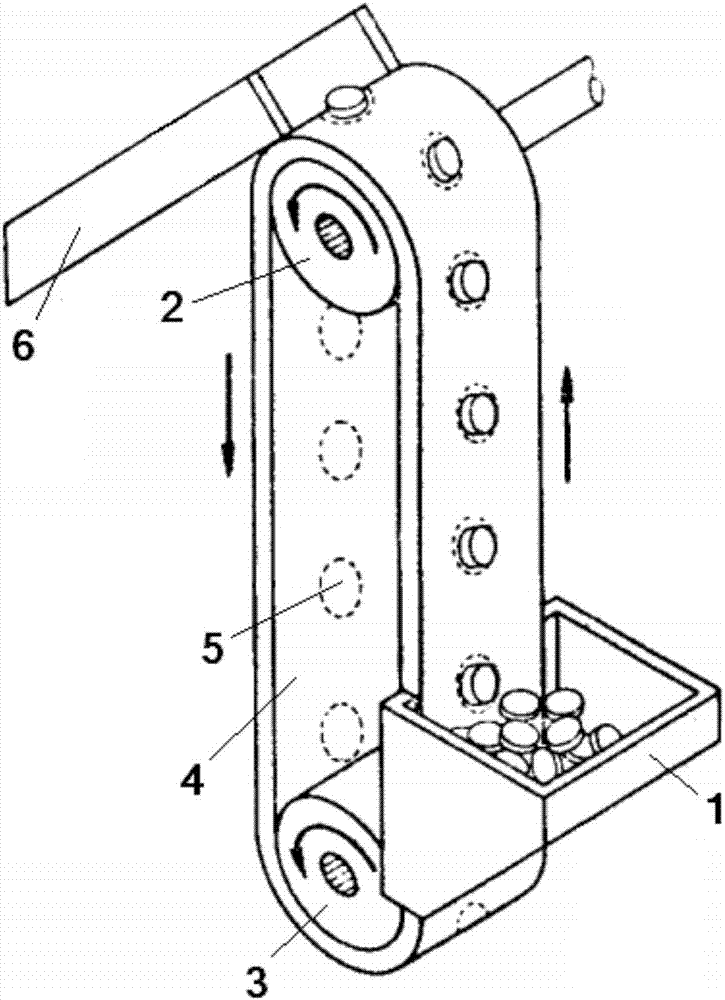

Adsorption-type feeding device

The invention discloses an adsorption-type feeding device. The adsorption-type feeding device comprises a rotating motor, a feeding hopper, a driving rotating wheel and a driven rotating wheel. A rotating shaft of the rotating motor is connected with the driving rotating wheel. The driven rotating wheel is arranged below the driving rotating wheel. The driving rotating wheel and the driven rotating wheel are connected through a belt. A periphery of magnets is uniformly embedded in the belt. A groove is formed in the front side of the feeding hopper. The outer side of the lower part of the beltis clamped into the groove of the feeding hopper. A sliding groove is formed in the outer side of the top of the belt. The front end of the sliding groove is tangent to the top of the belt. The adsorption-type feeding device is simple in structure, good in feeding effect and high in degree of automation.

Owner:JIANGSU MSIOO INTELLIGENT TECH CO LTD

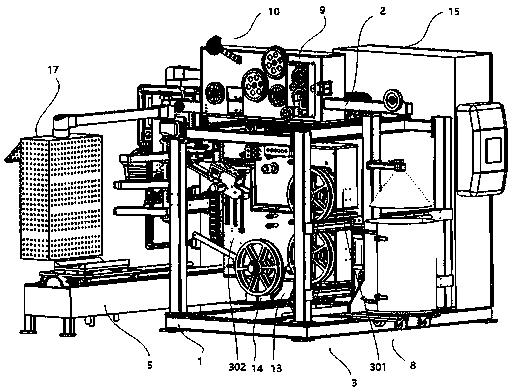

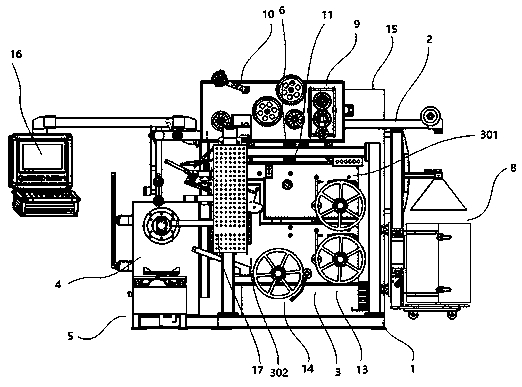

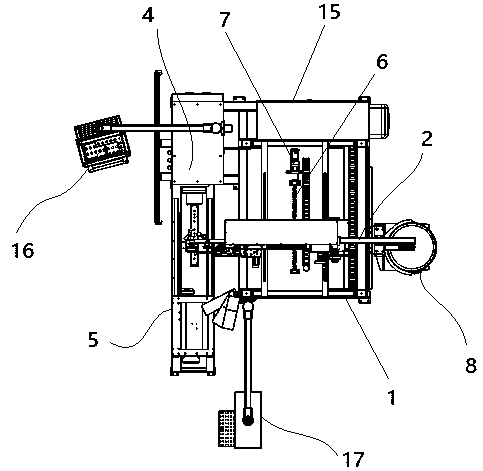

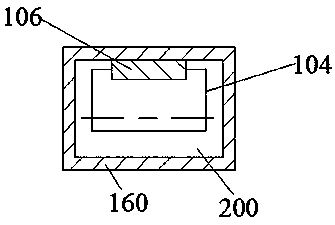

Automatic winding machine for high-voltage coil of power transformer

PendingCN111508703AIncrease productivityReasonable structureCoils manufactureWinding machineControl system

The invention discloses an automatic winding machine for a high-voltage coil of a power transformer. The automatic winding machine comprises a main rack, an electromagnetic wire pay-off rack, an insulation paper pay-off rack, a coil winding device, a coil unloading device and a control system, the electromagnetic wire pay-off rack is installed above the main rack. A first ball screw transmission mechanism is connected with the main rack in a front-back sliding manner; the first ball screw transmission mechanism is connected with a first servo motor; a round wire pay-off device, an electromagnetic wire flattening device and a constant-tension wire arranging device are arranged on the electromagnetic wire pay-off rack; the insulation paper discharging rack is located below the constant-tension wire arranging device and connected with the main rack in a front-back sliding mode through a second ball screw transmission mechanism, the second ball screw transmission mechanism is connected with a second servo motor, and an interlayer insulation discharging device and an end insulation feeding device are arranged on the insulation paper discharging rack. Product quality can be improved, production time is shortened, production cost is saved, and production efficiency of winding the transformer high-voltage wire package is improved.

Owner:江苏创凌非晶科技发展有限公司

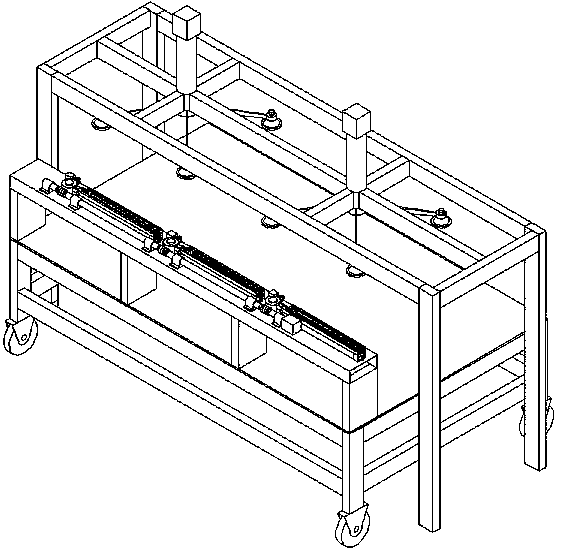

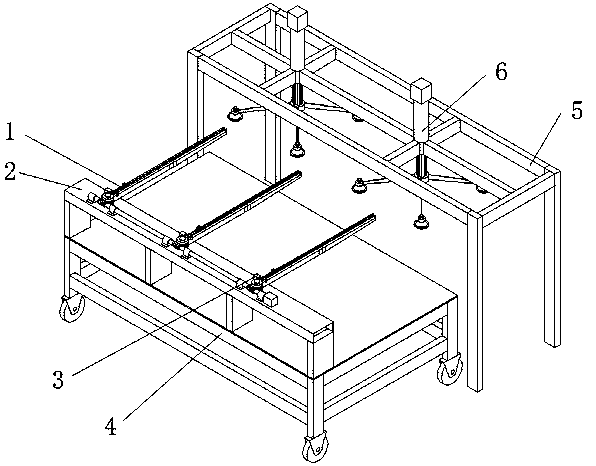

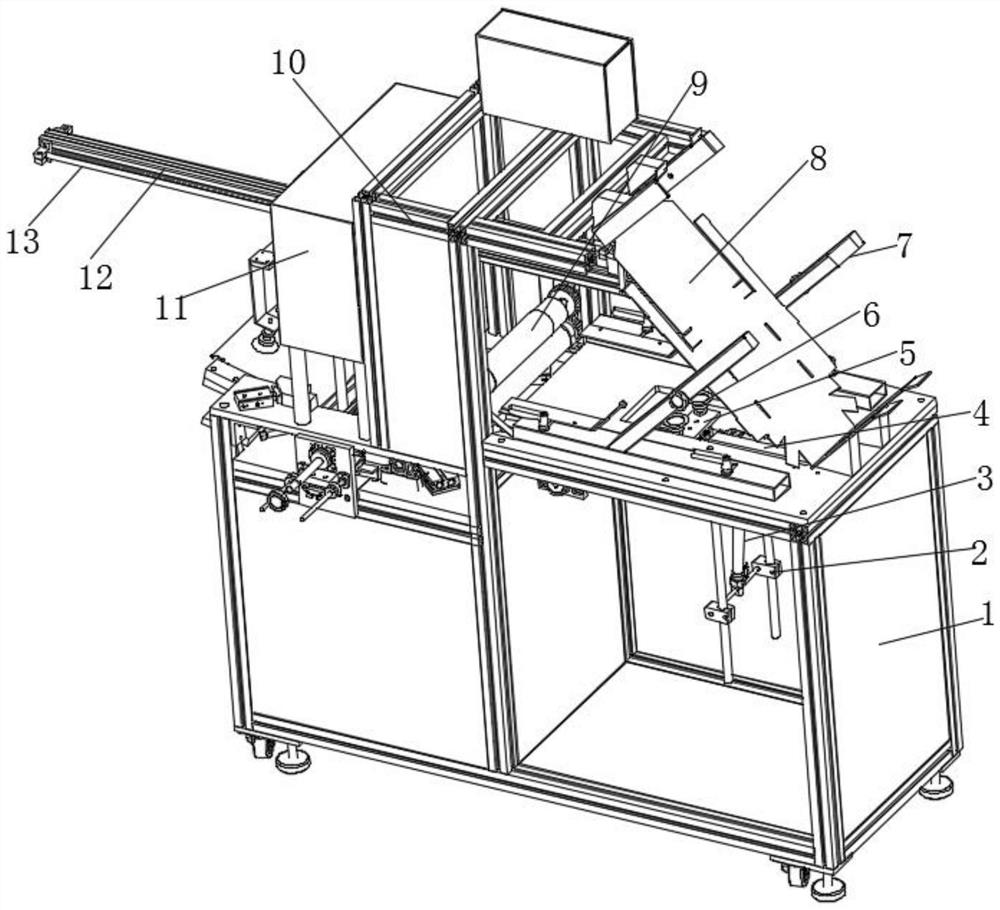

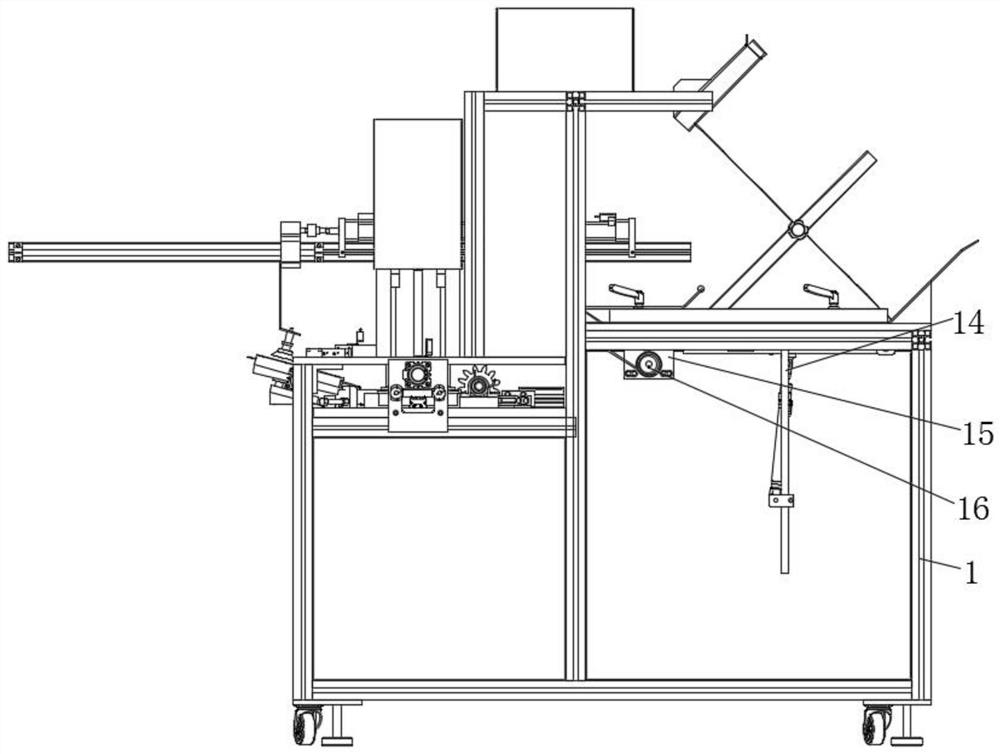

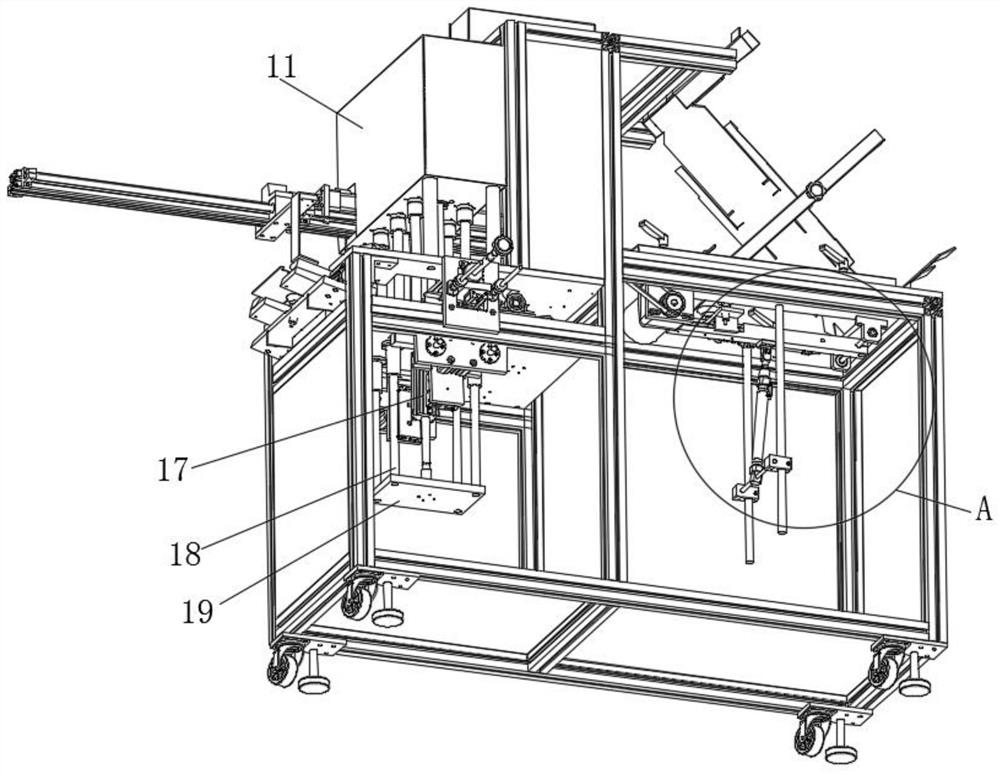

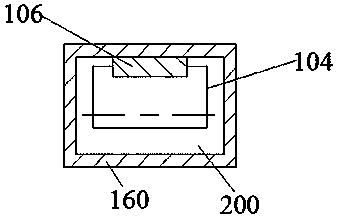

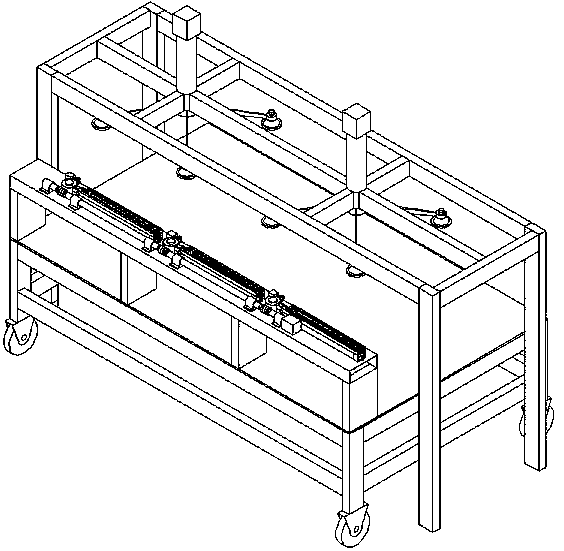

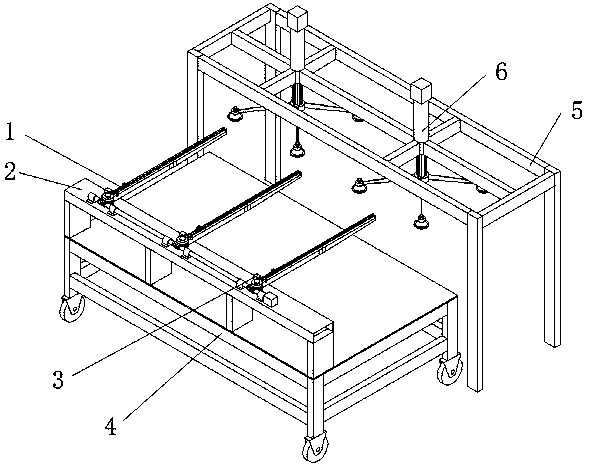

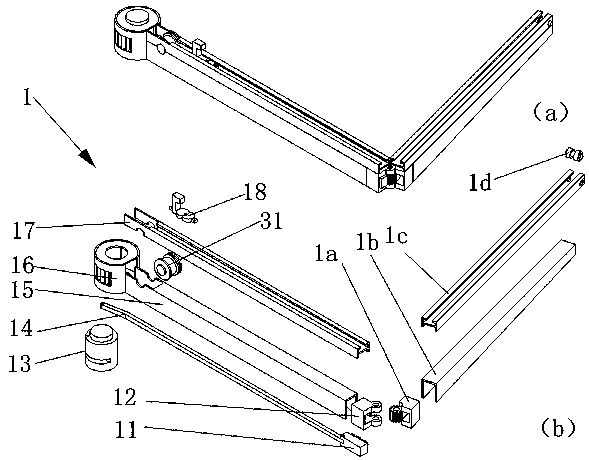

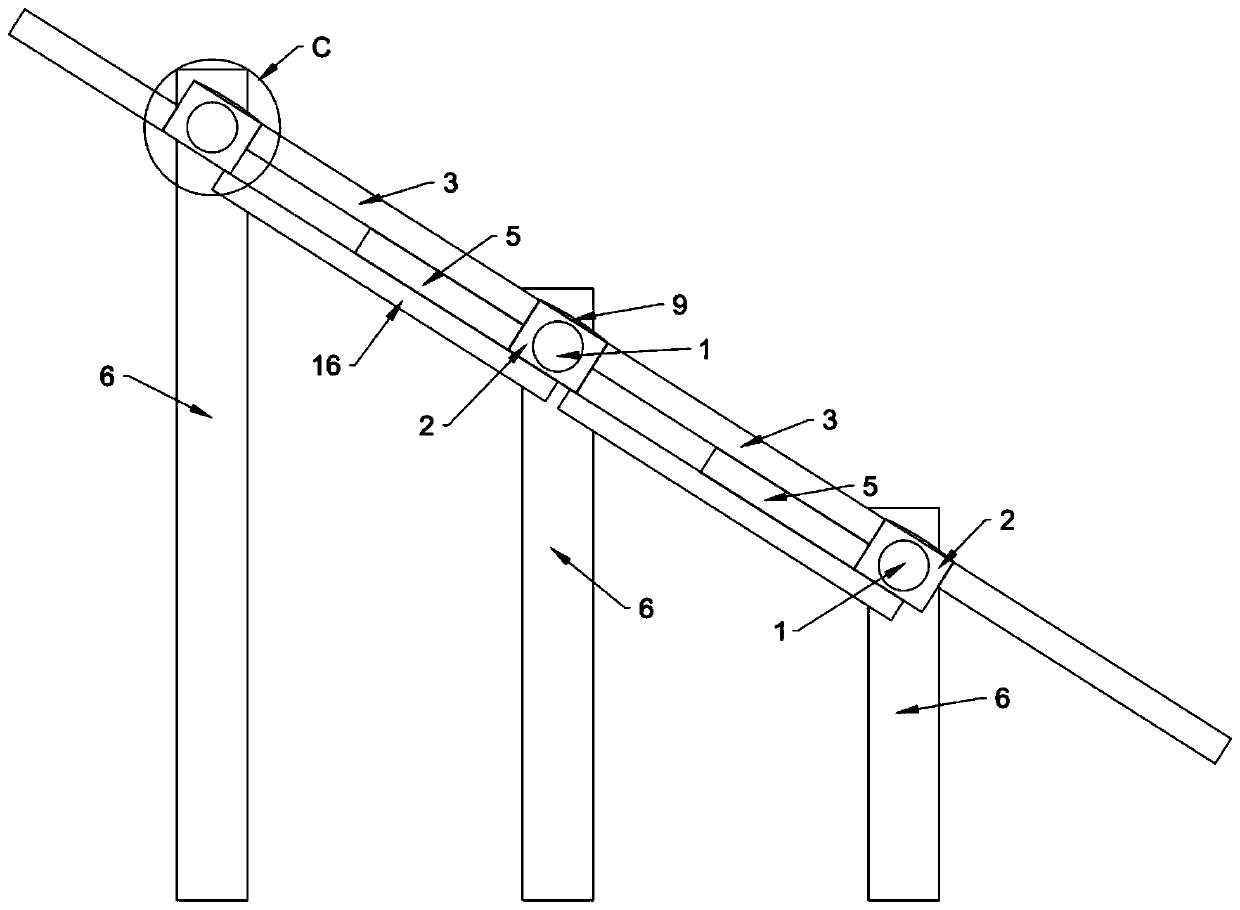

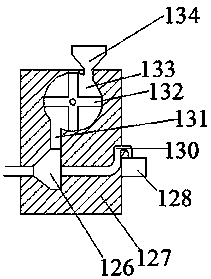

A sheet feeding device

ActiveCN109748103BRealize the feeding functionSimple structureStacking articlesDe-stacking articlesClassical mechanicsRocker arm

The invention discloses a thin plate feeding device. The thin plates are often stacked together, and when thin plates are processed, each thin plate needs to be put into a loading area of a processingdevice; the thin plate feeding device consists of a grasping and lifting system, a retaining and feeding system; the grasping and lifting system is provided with a sucking disk, the thin plates are sucked through the sucking disk, then the sucking disk drives the thin plates to rise above the retaining and feeding system, a rocker arm of the retaining and feeding system is unfolded, the thin plates are dropped onto the rocker arm, and a pushing mechanism pushes the thin plates into the loading area of the processing device along the upper side surface of the rocker arm to realize the thin plate feeding function; and according to the thin plate feeding device, the structure is simple, the space is small, and the cost is low.

Owner:李传聪

Carton bending forming device and working method thereof

InactiveCN111959035AImprove feeding efficiencyReduce labor intensityBox making operationsPaper-makingCylinder blockStructural engineering

The invention discloses a carton bending forming device. The device comprises a bottom frame and a middle frame, the middle frame is arranged at the top of the bottom frame, a placing frame is arranged on one side of the middle frame, a paperboard is placed in the placing frame, two vertical rods are arranged below the placing frame, the top ends of the two vertical rods are arranged on the innerwall of the top face of the bottom frame, fixing blocks are arranged on the two vertical rods correspondingly, and a first rotating rod is arranged between the two fixing blocks. According to the device, a paper box is sucked through a second suction cup, a third hydraulic cylinder controls a third piston rod therein to move towards the outer side of a cylinder body, a through hole is formed in asliding block, and a sliding rod penetrates through the interior of the through hole in the sliding block so that a clamping base can move along the sliding rod to move out the processed paper box from the device, the discharging work is facilitated, the situation that the paper box sucked by the second suction cup falls off due to shaking generated when the clamping base moves on a long plate isavoided, the discharging time is saved, the operation and use of the whole device can be completed by one person, and the manpower is saved.

Owner:王娜娜

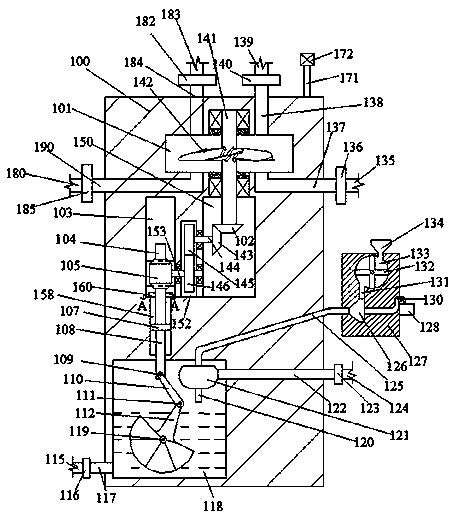

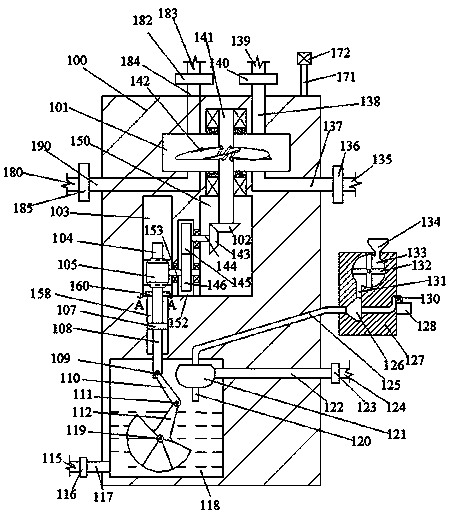

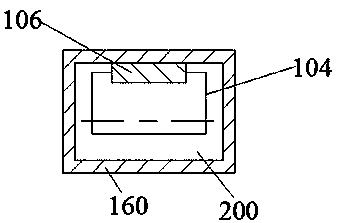

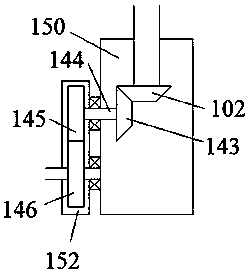

Novel kitchen garbage disposer

The invention discloses a novel kitchen garbage disposer, which comprises a base, wherein the base is internally provided with a kinetic energy cavity, and a first transfer cavity positioned in the base is arranged in the kinetic energy cavity; a second transfer cavity positioned in the base is arranged at the left side of the first transfer cavity, and a third transfer cavity positioned in the base is arranged at the left side of the second transfer cavity; a retracting cylinder is arranged in the lower end wall of the third transfer cavity in a communicating way, and a first tubular member and a second tubular member which extend up to the outside are bilaterally symmetrically arranged in the upper end wall of the kinetic energy cavity in a communicating way; a first gate valve is arranged on the upper end surface of the first tubular member in a communicating way, and a second gate valve is arranged on the upper end surface of the second tubular member in a communicating way; a third tubular member is arranged on the upper end surface of the first gate valve in a communicating way, and a fourth tubular member is arranged on the upper end surface of the second gate valve in a communicating way. The device disclosed by the invention is simple in structure and is convenient to use, and the device adopts a low-temperature steam-driven cam structure to mash the garbage, thereby effectively improving work efficiency.

Owner:杨丽君

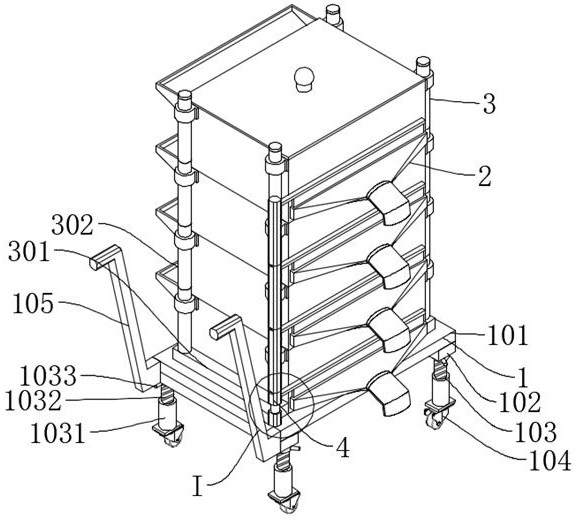

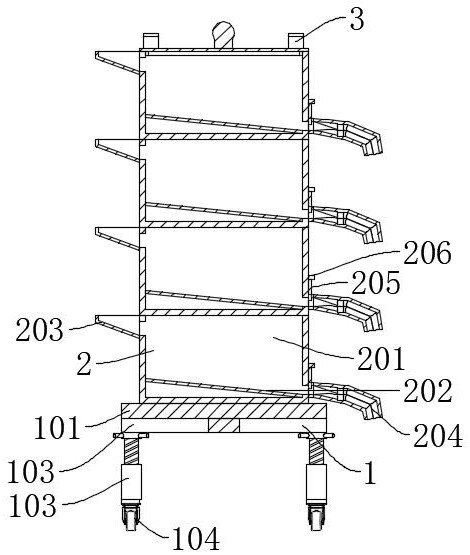

Feed adding device for chicken breeding

InactiveCN112088803ARealize the function of closing nestingAchieve fixationLifting devicesAvicultureAnimal scienceEngineering

The invention discloses a feed adding device for chicken breeding. The feed adding device comprises a height-adjustable moving trolley, and further comprises a plurality of feed adding mechanisms capable of being vertically combined, a fixing mechanism and a driving mechanism; each feed adding mechanism comprises a storage box, a flow guide plate, a charging hopper, a discharging pipe, an inserting plate, a connecting rod and a sliding sleeve; the storage boxes are connected to the top of the moving trolley through bolts, the obliquely-arranged flow guide plates are welded to the bottoms of the inner sides of the storage boxes, a charging port is formed in one side of each storage box, and the charging hoppers are connected to the outer sides of the charging ports through bolts. The numberof the storage boxes can be set according to the actual layer number of chicken coop, the function of charging all layers of chicken coop at a time is achieved, then the charging time is shortened, and operation is simplified.

Owner:湖南过龙岭生态农业科技股份有限公司

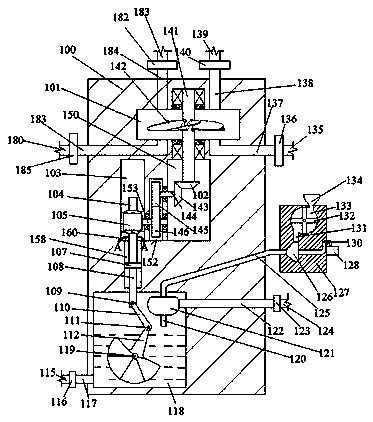

Novel industrial lathe device

InactiveCN108479568AEasy to installEasy maintenanceShaking/oscillating/vibrating mixersTransportation and packagingEngineeringCam

The invention discloses a novel industrial lathe device. The novel industrial lathe device comprises a machine body. The machine body is internally provided with a force transmitting channel, a firsttransmission cavity positioned in the machine body is installed below the force transmitting channel, the left side of the first transmission cavity is provided with a second transmission cavity positioned in the machine body, the left side of the second transmission cavity is provided with a third transmission cavity positioned in the machine body, the lower end wall of the third transmission cavity is internally communicated and provided with a telescopic cylinder, the upper end wall of the force transmitting channel is internally leftwards and rightwards symmetrically communicated and provided with a first pipe and a second pipe which are upwards extended to the exterior, the upper end face of the first pipe is communicated and provided with a first switch valve, the upper end face of the second pipe is communicated and provided with a second switch valve, the upper end face of the first switch valve is communicated and provided with a third pipe, the upper end face of the second switch valve is communicated and provided with a fourth pipe. The device is simple in structure, and convenient to use. The device uses a low-temperature steam driving cam structure to stir a material,so that the working efficiency is effectively improved.

Owner:童浩

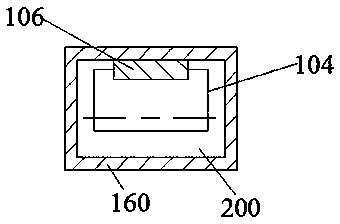

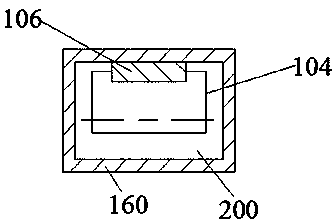

Thin plate feeding device

ActiveCN109748103ARealize the feeding functionSimple structureStacking articlesDe-stacking articlesEngineeringRocker arm

The invention discloses a thin plate feeding device. The thin plates are often stacked together, and when thin plates are processed, each thin plate needs to be put into a loading area of a processingdevice; the thin plate feeding device consists of a grasping and lifting system, a retaining and feeding system; the grasping and lifting system is provided with a sucking disk, the thin plates are sucked through the sucking disk, then the sucking disk drives the thin plates to rise above the retaining and feeding system, a rocker arm of the retaining and feeding system is unfolded, the thin plates are dropped onto the rocker arm, and a pushing mechanism pushes the thin plates into the loading area of the processing device along the upper side surface of the rocker arm to realize the thin plate feeding function; and according to the thin plate feeding device, the structure is simple, the space is small, and the cost is low.

Owner:李传聪

Automatic soldering apparatus suitable for integrated circuitry

InactiveCN109249104ARealize the feeding functionPrinted circuit assemblingMetal working apparatusDrive shaftEngineering

The invention discloses an automatic soldering apparatus suitable for integrated circuitry. The output end of a driving motor is rotationally connected with a driving shaft; the driving motor is connected with a power source and a switch via wires; the end of the driving shaft is fixedly connected with a turnplate; the outer edge of the turnplate is rotationally connected with the upper end of a connection bar; the lower end of the connection bar is rotationally connected with the lower portion of a storage gun; a first bevel gear is fixedly connected to the driving shaft; a second bevel gearis engaged with the top of the first bevel gear and is fixedly connected with the lower end of a crankshaft; an injection pipe is fixedly connected to the top of a top plate. the middle bend of the crankshaft is sleeved with the end of a push bar; the other end of the push bar is rotationally connected with the side of a piston; the edge of the piston is hermetically and slidably connected with the inner wall of the injection pipe. The automatic soldering apparatus provides spot welding by: driving the turnplate to rotate via the driving shaft and enabling the connection bar to drive the storage gun to reciprocate up and down under the action of slide feet and slide grooves.

Owner:刘慧华

Novel chemical powder mixing device

InactiveCN108393028AImprove the mixing effectEasy to installTransportation and packagingMixer accessoriesCompound (substance)Engineering

The invention discloses a novel chemical powder mixing device, which comprises a box body, wherein the box body is internally provided with a power cavity, and a first transmission cavity positioned in the box body is arranged below the power cavity; a second transmission cavity positioned in the box body is arranged at the left side of the first transmission cavity, and a third transmission cavity positioned in the box body is arranged at the left side of the second transmission cavity; a piston barrel is arranged in the lower end wall of the third transmission cavity in a communicating way,and a first pipeline and a second pipeline which extend up to the outer space are bilaterally symmetrically arranged on the upper end wall of the power cavity in a communicating way; the upper end surface of the first pipeline is communicated with a first valve, and the upper end surface of the second pipeline is communicated with a second valve; the upper end surface of the first valve is communicated with a third pipeline, and the upper end surface of the second valve is communicated with a fourth pipeline. The device disclosed by the invention is simple in structure and is convenient to use, and the device adopts a low-temperature steam-driven cam structure to stir chemicals, thereby effectively improving work efficiency.

Owner:广州念泽环保科技有限公司

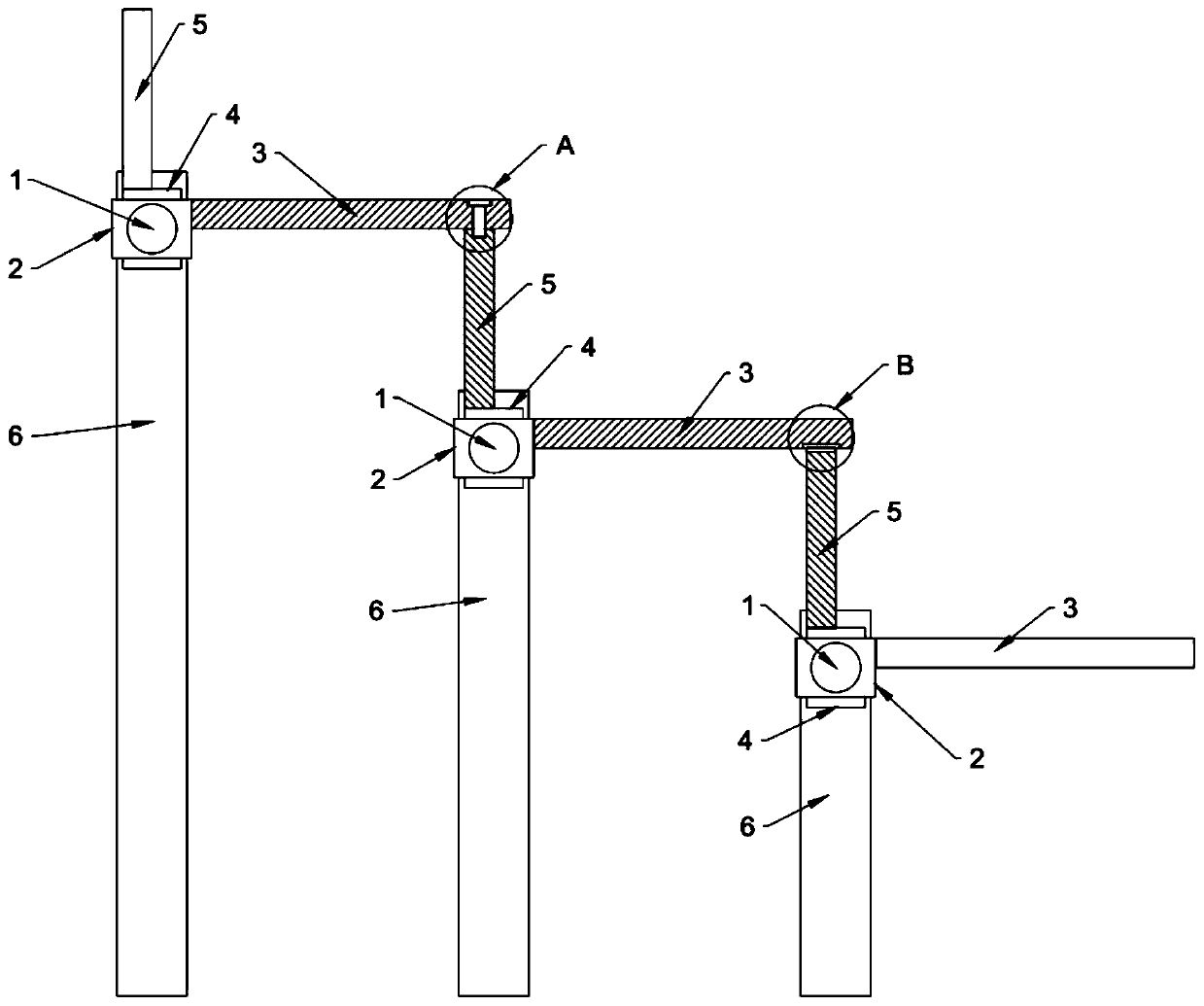

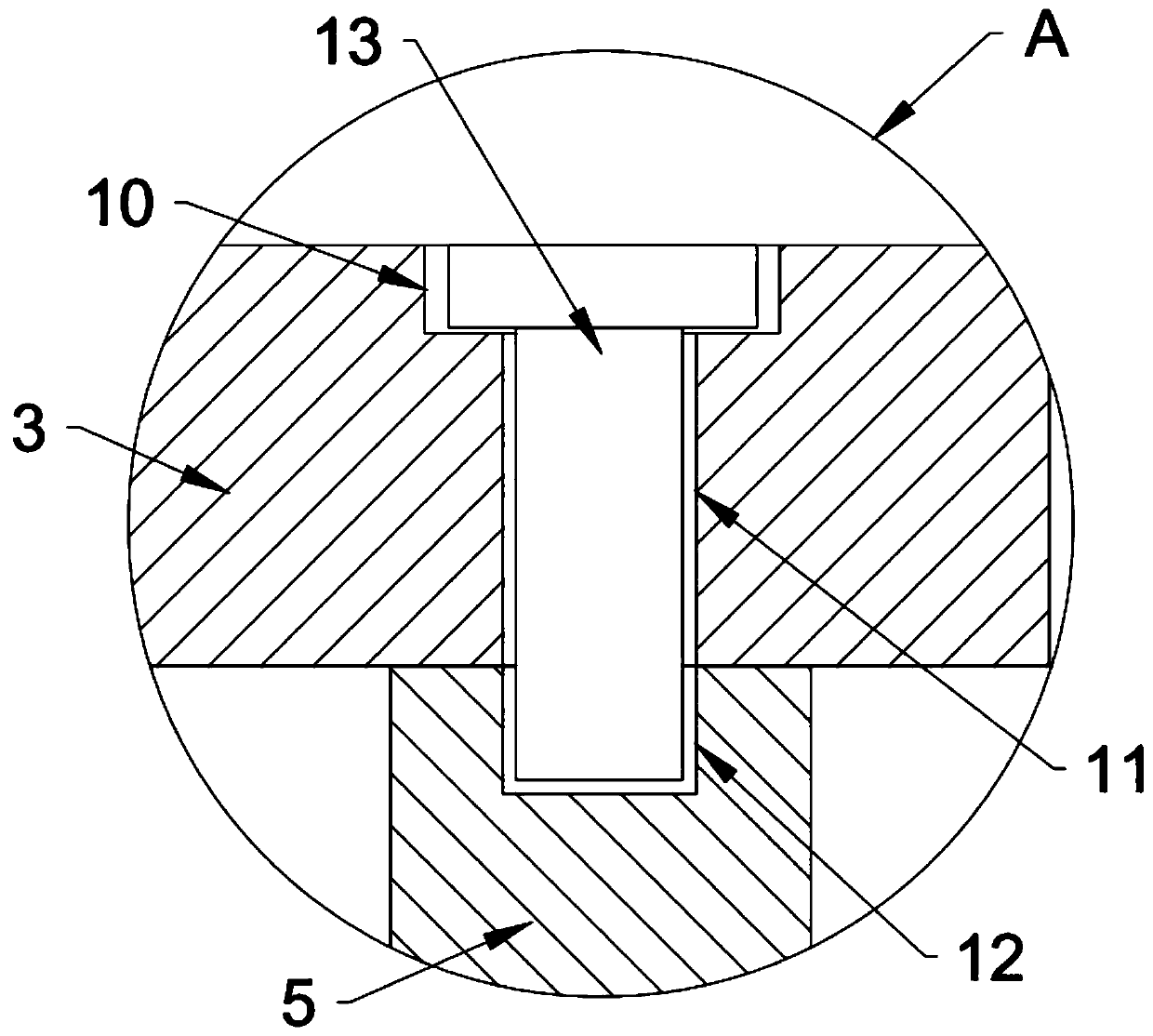

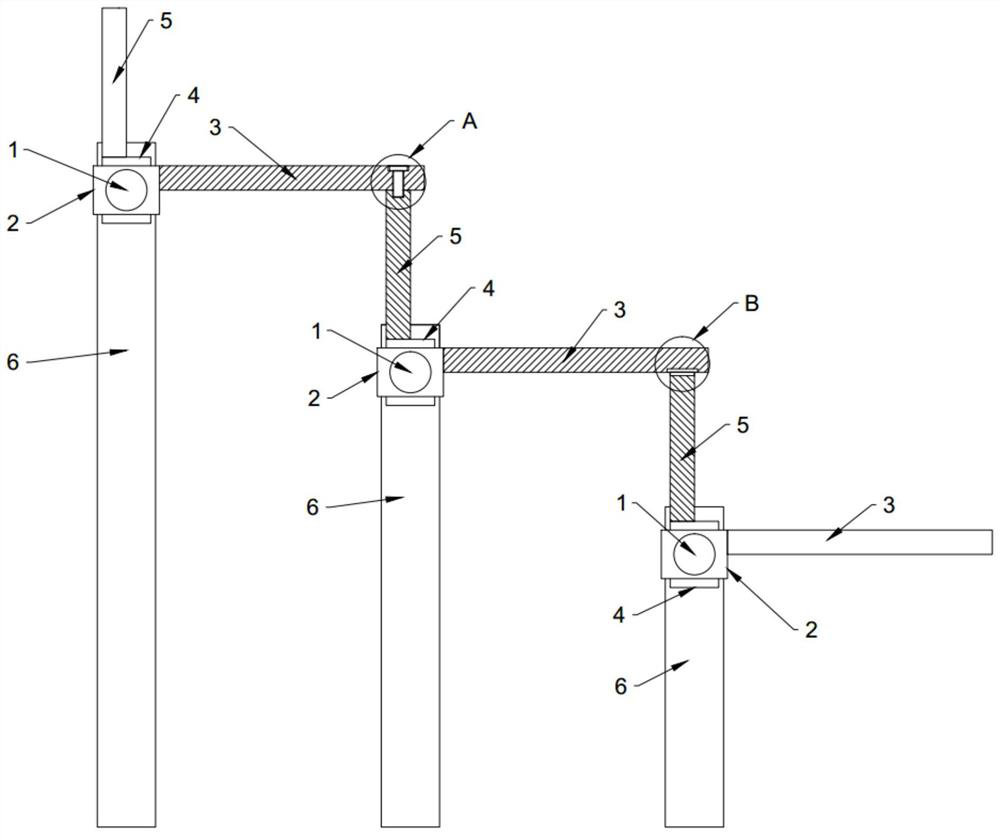

Steel structure building stair capable of switching feeding surfaces

ActiveCN110017002AEasy to operateStable structureTreadsTread-and-riser unitsAgricultural engineeringEngineering

The invention discloses a steel structure building stair capable of switching feeding surfaces. The stair comprises a plurality of steel structure stair units, the plurality of steel structure stair units are sequentially arranged in a height reduction manner from left to right; and based on each steel structure stair unit, a fixed shaft, a horizontal stair plate and a vertical stair plate are included, the fixed shaft is symmetrically sleeved by two horizontal sleeve blocks, the horizontal sleeve block is rotationally connected with the fixed shaft, and the upper end of the right side of thehorizontal sleeve block is fixedly connected with the horizontal stair plate, two vertical sleeve blocks are arranged between the two horizontal sleeve blocks on the fixed shaft in a sleeved mode androtationally connected with the fixed shaft, and the vertical stair plate is fixedly connected to the left sides of the upper ends of the vertical sleeve blocks. According to the invention, only a damaged structure needs to be simply replaced, and the building stair can continue to be used and is very simple; therefore, one-time operation does not need to be carried out on the whole structure whenswitching is carried out each time, and the step type or inclined plane type switching is more labor-saving and more convenient.

Owner:江苏华木空间结构有限公司

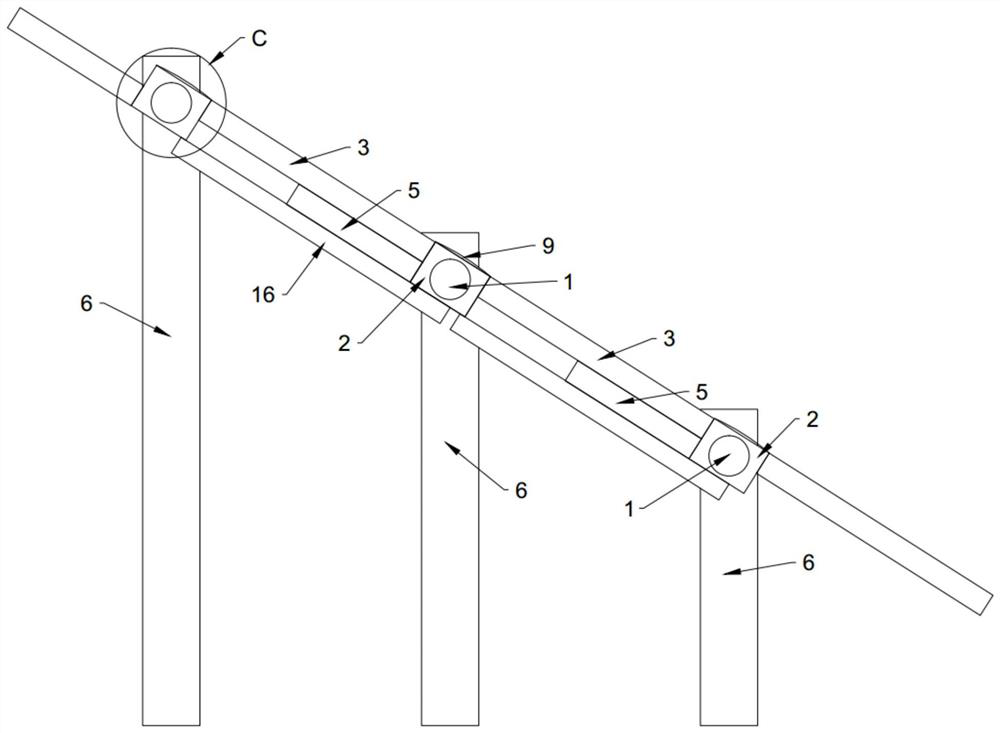

Feeding device for metal tube cutting

ActiveCN108994736AAvoid misalignmentGuaranteed stabilityAbrasive machine appurtenancesAbrasive blasting machinesEngineeringMetal

The invention discloses a feeding device formetal tube cutting, and belongs to the technical field of metal tube processing. The feeding device for the metal tube cutting comprises a base, wherein twofixed seats symmetrically distributed are connected with the top edge of the base, a rotating shaft is movably connected between the fixed seats, two ring jackets are arranged at the middle section of the rotating shaft in a sleeving manner, a positioning plate is connected with the outer walls of the ring jackets, the rotating shaft extends to both ends after penetrating through the fixed seats,the extending ends of the rotating shaft are movably connected with limiting baffles, a feeding plate is connected between the limiting baffles, a working platform is connected between the feeding plate and the positioning plate, a first supporting bracket is connected with the limiting baffle, and a fastening assembly is connected with the first supporting bracket. The device disclosed in the invention is simple in structure, can feed automatically, saves the labor, and improves the work efficiency; and due to the design of a multiple feeding control structure, the stability of the feeding is improved, and a problem of material overflowing during the feeding process is effectively avoided.

Owner:SHENZHEN OUYATE ELECTRICAL APPLIANCE EQUIP

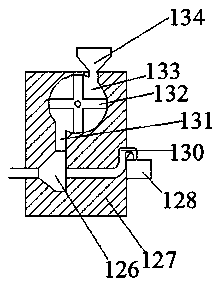

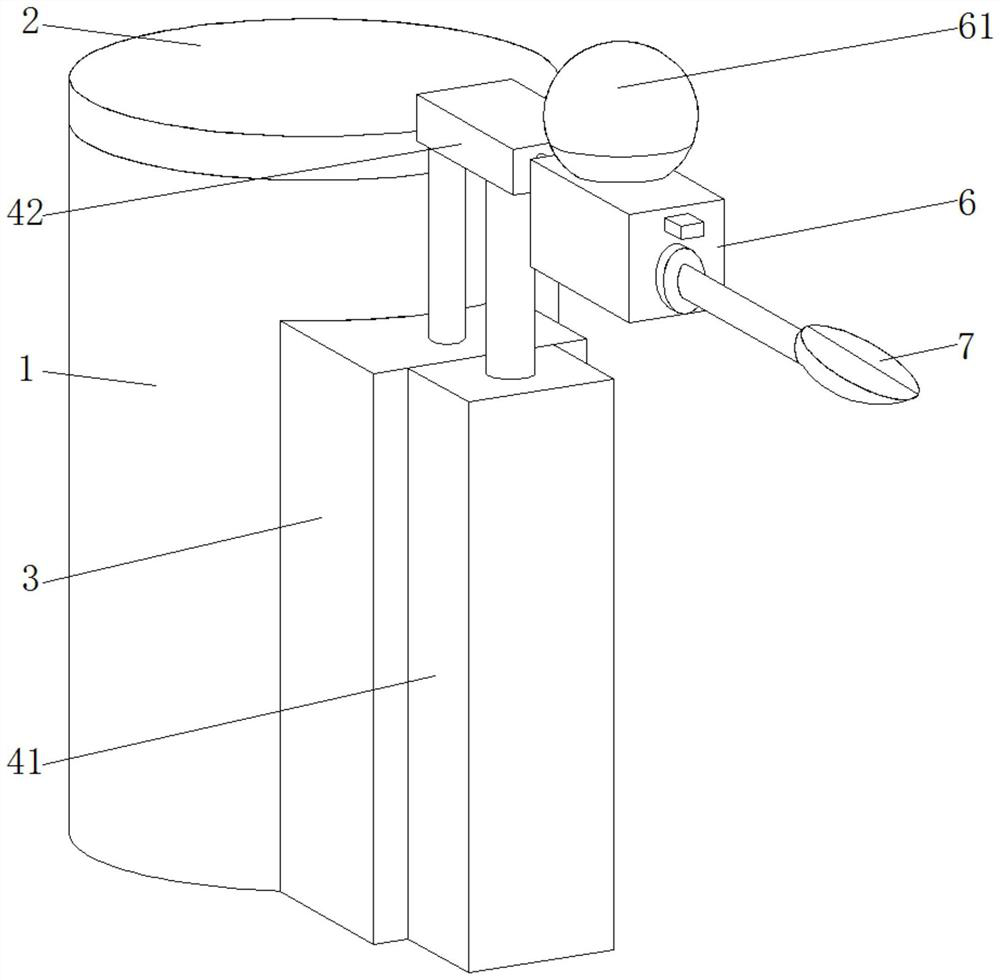

Feeding device suitable for esophageal cancer patient

PendingCN114848478AEasy to control speedConvenient frequency controlPharmaceutical product form changeFeeding-tubesEngineeringEsophageal cancer

The invention discloses a feeding device suitable for esophageal cancer patients, comprising: a crushing cylinder, the inner wall of which is provided with ear plates; the cylinder cover is buckled at the top end of the crushing cylinder, and a circular groove and an annular groove are formed in the bottom surface of the cylinder cover; a heating plate is mounted on the inner wall of the heating box; the moving mechanism comprises a vertical air cylinder and a horizontal air cylinder; the crushing cutter is arranged on the side face of the cover cap, and the bottom end of the cover cap is rotationally connected with the sleeve; a camera is mounted on the top surface of the connecting box; the feeding spoon is connected to the connecting box in an inserted mode; the filter screen is fixed on the sleeve; and the grinding mechanism is mounted at the bottom of the crushing barrel. According to the feeding device suitable for the esophageal cancer patient, food is smashed and disinfected through the smashing cylinder, the smashed food is further processed through the filter screen and the grinding mechanism, part of residues are prevented from remaining in liquid food, and the amount of the food entering the feeding spoon is controlled through the metering pump.

Owner:川北医学院附属医院

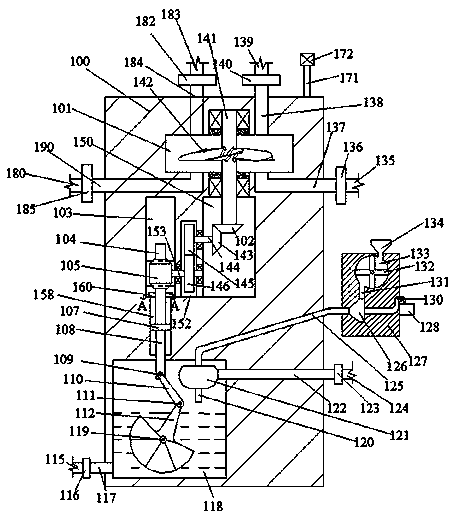

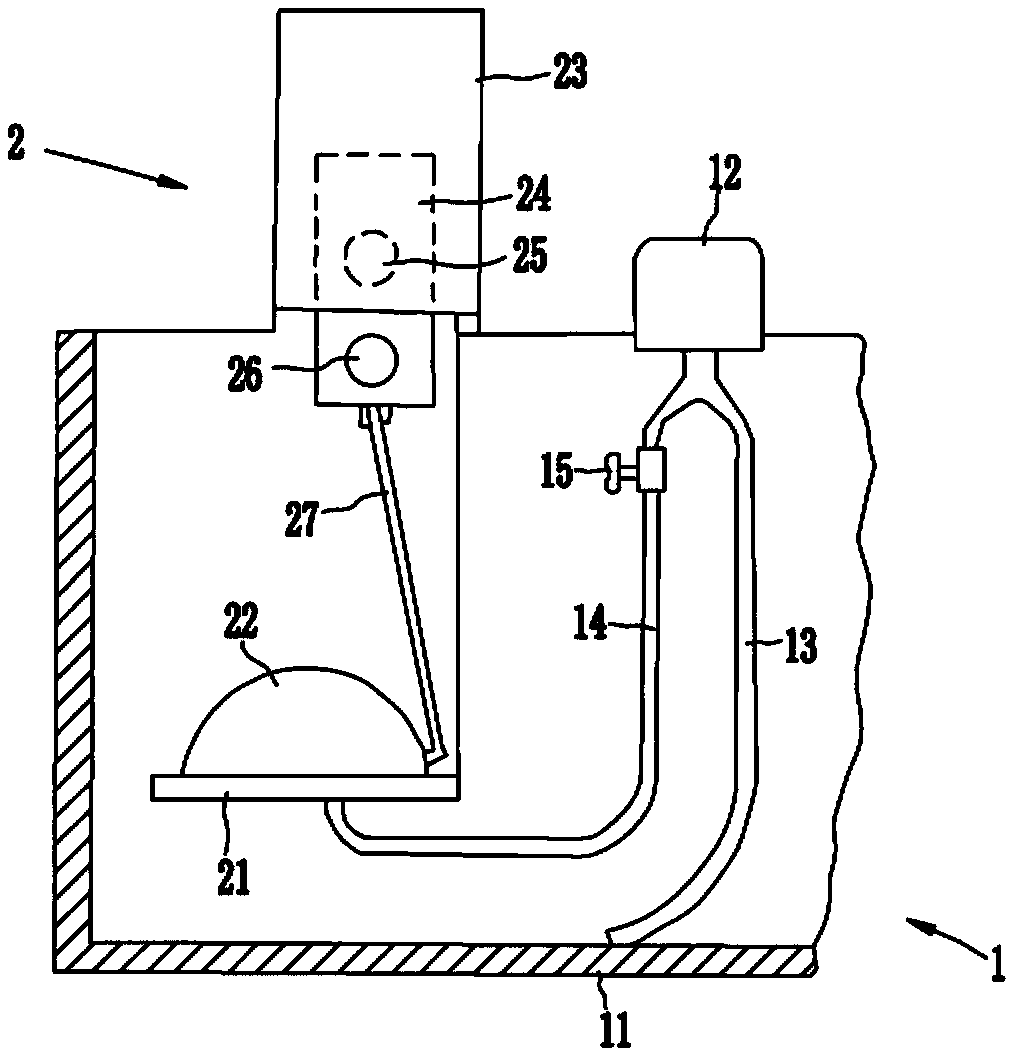

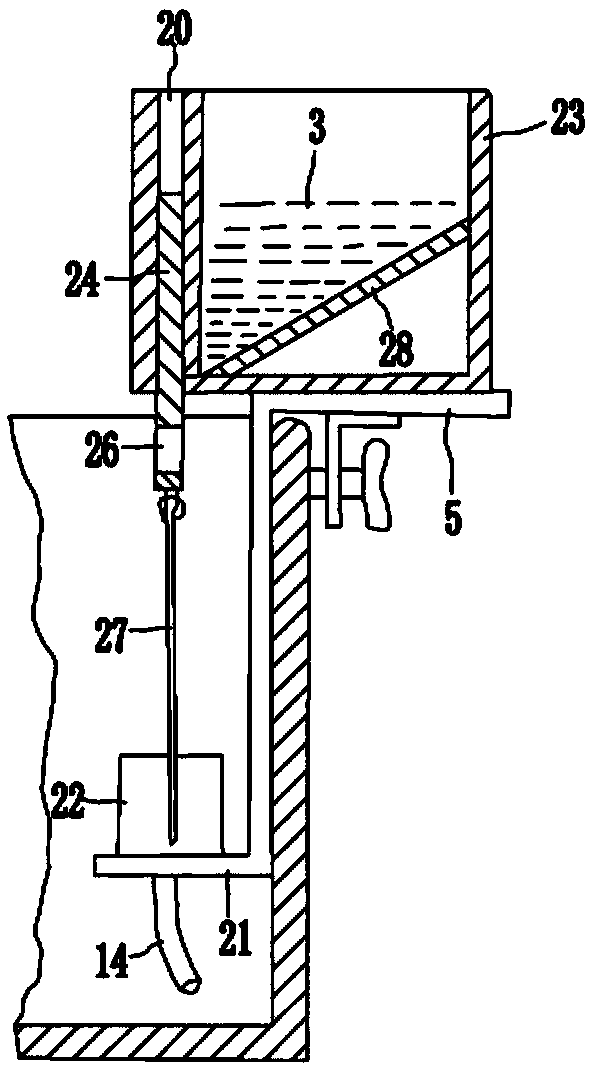

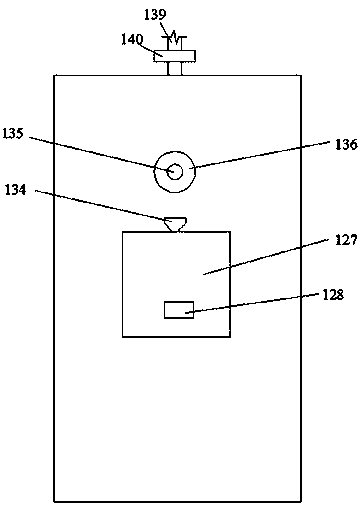

Automatic timing feeding system

PendingCN108782397ARealize the feeding functionClimate change adaptationPisciculture and aquariaEngineeringFish pond

The invention provides a small automatic timing fish pond feeding system. The small automatic timing fish pond feeding system is simple in structure and good in stability and can automatically conductfeeding regularly. The small automatic timing fish pond feeding system comprises a blowing assembly and a feeding assembly which are arranged in a pond body, and the blowing assembly comprises an inflating pump outside the pond body, a hemispherical hollow inverted container in water in the pond body, an air guide tube of which the two ends are connected with the inflating pump and the inverted container respectively, and a mounting rack for mounting the inverted container; when a sealing plate slides along a vertical sliding groove in place, a discharging port is aligned with a through holein the sealing plate, feed in a feed hopper flows out and is placed on the through hole, along with gradual opening of the inverted container, filling air in the inverted container gradually escapes and descends under the effect of self gravity, and then the sealing plate is driven to gradually descend; when the through hole moves out of the vertical sliding groove, the feed on the through hole ispoured into the water in the pond body, and thus the feeding function is achieved.

Owner:重庆市开州区博洋生态农业发展有限公司

Labeling device capable of improving labeling quality

PendingCN114772002AImprove firmnessRealize the feeding functionLabelling machinesLabelling machineAutomatic processing

The invention relates to the technical field of automatic processing, in particular to a labeling device capable of improving labeling quality, which comprises a base, a bracket, a labeling mechanism and a conveying mechanism, the feeding assembly is arranged on the support. The first roller is rotatably arranged on the bracket below the feeding assembly; the two ends of the transmission assembly are arranged on the feeding assembly and the first rolling wheel correspondingly. The grooves are formed in the circumferential side wall of the first roller in the radial direction of the first roller; the sliding block is arranged in the groove in a sliding mode in the length direction of the groove. The limiting assembly is arranged in the groove and used for preventing the sliding block from sliding out of the groove. The second roller is rotatably arranged on the base below the first roller; and the first magnet is fixedly arranged on the circumferential side wall of the second roller. The re-pressing mechanism and the labeling mechanism are arranged, so that the labeling firmness of the labeling device is improved, and the product yield is increased.

Owner:日达智造科技(如皋)有限公司

Novel advanced wastewater treatment device

InactiveCN108435074AEasy to installEasy maintenanceShaking/oscillating/vibrating mixersTransportation and packagingWastewaterEngineering

The invention discloses a novel advanced wastewater treatment device. The novel advanced wastewater treatment device comprises a base body, wherein an energy feeding cavity is formed in the base body,wherein a first conduction cavity located in the base body is arranged below the energy feeding cavity; a second conduction cavity located in the base body is formed in the left side of the first conduction cavity; a third conduction cavity located in the base body is formed in the left side of the second conduction cavity; a piston part is arranged in the lower end wall of the third conduction cavity in a connecting manner; a first hollow pipe and a second hollow pipe which upwards extend to the outside are arranged in the upper end wall of the energy feeding cavity in a bilaterally symmetric connecting manner; a first open and close valve is arranged on the upper end surface of the first hollow pipe in a connecting manner; a second open and close valve is arranged on the upper end surface of the second hollow pipe in a connecting manner; a third hollow pipe is arranged on the upper end surface of the first open and close valve in a connecting manner; a fourth hollow pipe is arrangedon the upper end surface of the second open and close valve in a connecting manner. The novel advanced wastewater treatment device is simple in structure and convenient to use and adopts a low-temperature steam driven cam structure for stirring sewage, and working efficiency is effectively improved.

Owner:黄杰东

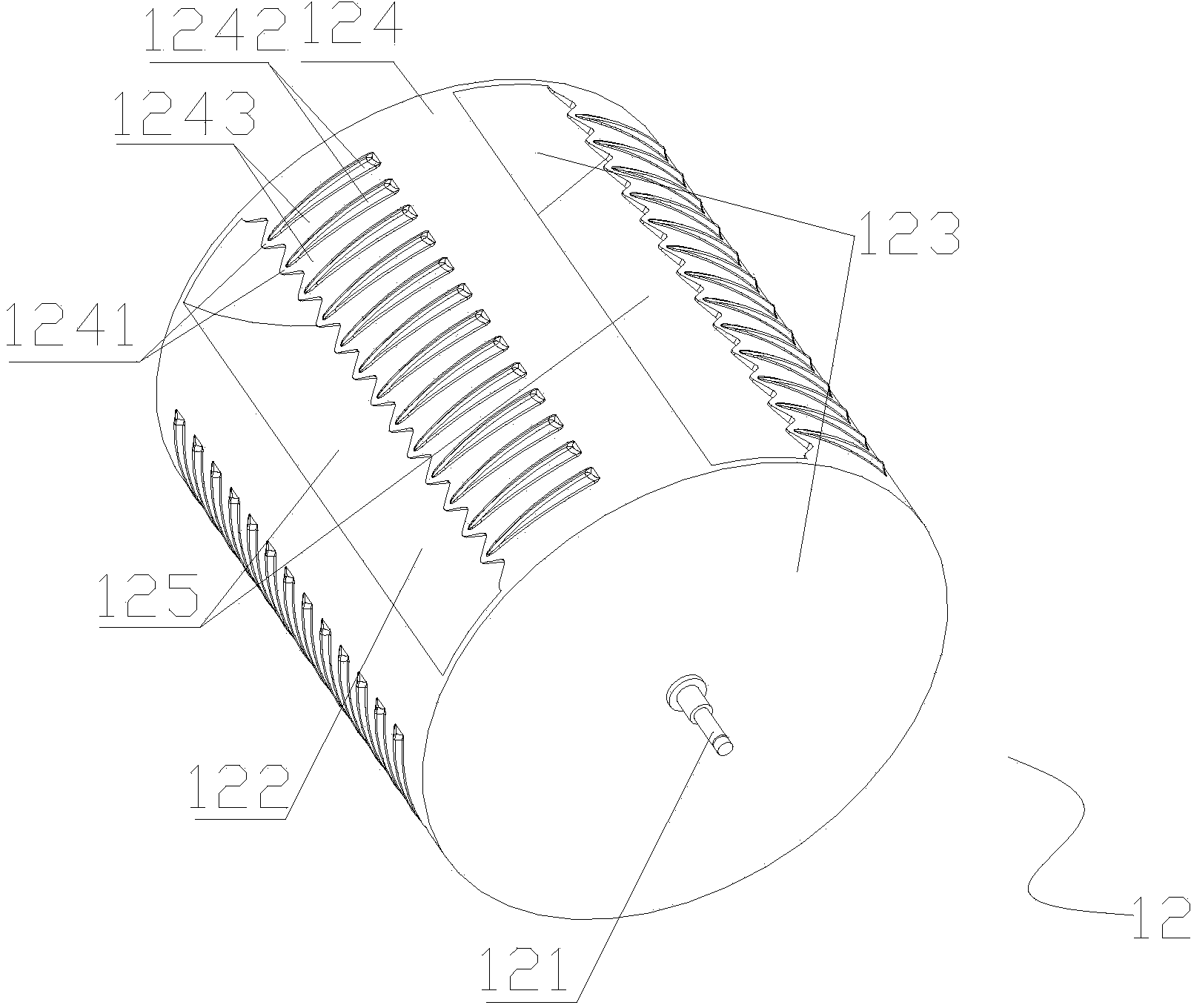

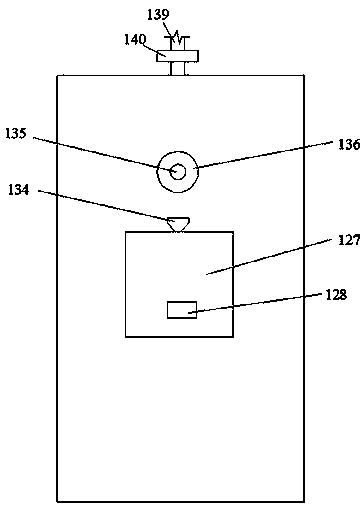

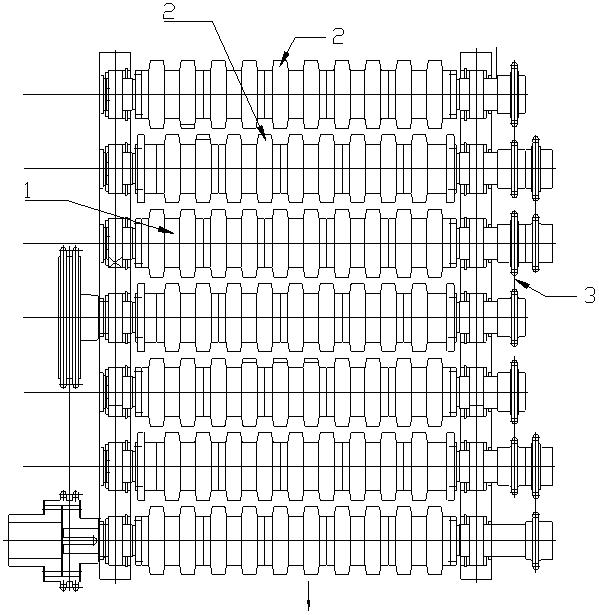

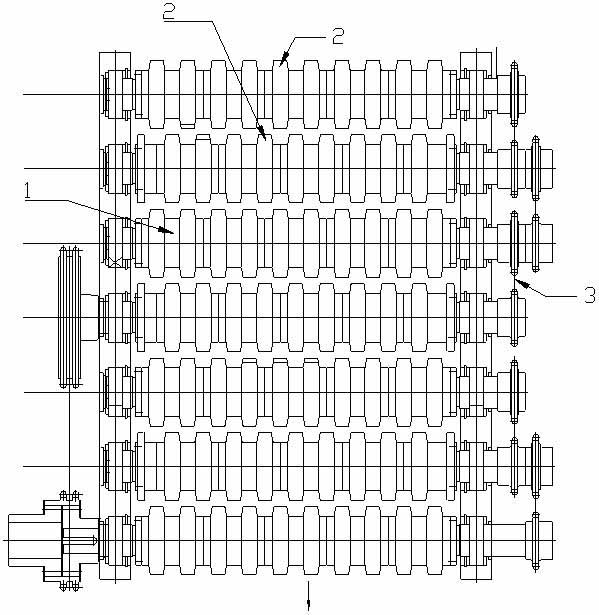

Roller screen of roller type feeding machine

InactiveCN102430463AIncrease production capacityImprove efficiencyGrain treatmentsEngineeringMechanical engineering

The invention provides a roller screen of a roller type feeding machine, which has feeding capacity and a screening function. The roller screen comprises more than two roller shafts which are rotated in the same direction under the drive action of a transmission mechanism, wherein rollers are arranged on the roller shafts along the axial direction; and the rollers on adjacent two roller shafts are staggered in the axial direction.

Owner:SINOMA LIYANG HEAVY MACHINERY

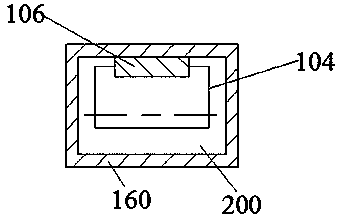

Industrial machine tool equipment

InactiveCN108554296AImprove work efficiencyEasy to installTransportation and packagingMixer accessoriesEngineeringCam

The invention discloses industrial machine tool equipment. The industrial machine tool equipment comprises a machine body, wherein the machine body is internally provided with a force transmission groove; a first transmission cavity, which is located in the machine body, is formed below the force transmission groove; a second transmission cavity, which is located in the machine body, is formed inthe left side of the first transmission cavity; a third transmission cavity, which is located in the machine body, is formed in the left side of the second transmission cavity; a retractable barrel isarranged in a lower end wall of the third transmission cavity; a first pipe body and a second pipe body, which upwards stretch out, are bilaterally symmetrically arranged in an upper end wall of theforce transmission groove in a communication manner; a first switching valve is arranged on an upper end face of the first pipe body in a communication manner; a second switching valve is arranged onthe upper end face of the second pipe body in the communication manner; a third pipe body is arranged on the upper end face of the first switching valve in a communication manner; a fourth pipe body is arranged on the upper end face of the second switching valve in a communication manner. The device disclosed by the invention is simple in structure and convenient to use; the equipment adopts low-temperature steam to drive a cam structure to stir materials, so that the working efficiency is effectively improved.

Owner:童浩

Air purification and deodorization device

InactiveCN108404611AEasy to installEasy maintenanceShaking/oscillating/vibrating mixersRotary stirring mixersDeodorantEngineering

The invention discloses an air purification and deodorization device. The air purification and deodorization device comprises a frame body, wherein a movable rotating cavity is formed in the frame body; a first passing and receiving cavity which is located in the frame body is formed below the movable rotating cavity; a second passing and receiving cavity which is located in the frame body is formed on the left side of the first passing and receiving cavity; a third passing and receiving cavity which is located in the frame body is formed on the left side of the second passing and receiving cavity; a piston body is arranged in the lower end wall of the third passing and receiving cavity in a communicating way; a first empty adapter tube and a second empty adapter tube which extend upwardsand out are arranged in the upper end wall of the movable rotating cavity in a communicating and bilaterally symmetric way; a first valve body is arranged on the upper end face of the first empty adapter tube in a communicating way; a second valve body is arranged on the upper end face of the second empty adapter tube in a communicating way; a third empty adapter tube is arranged on the upper endface of the first valve body in a communicating way; a fourth empty adapter tube is arranged on the upper end face of the second valve body in a communicating way. The device has a simple structure, and is convenient to use. In the device, a low-temperature steam driving cam structure is adopted to stir a deodorant, thus effectively improving the working efficiency.

Owner:黄杰东

Kitchen garbage disposer

InactiveCN108547357AFacilitate installation and maintenanceEasy to installDomestic plumbingEngineeringCam

The invention discloses a kitchen garbage disposer comprising a base, wherein the base is provided with a kinetic energy chamber, a first transfer chamber located in the base is disposed below the kinetic energy chamber, a second transfer chamber r located in the base is disposed on the left side of the first transfer chamber, a third transfer chamber located in the base is disposed on the left side of the second transfer chamber, a shrinkage tube is disposed in the lower end wall of the third transfer chamber in an intercommunication manner, a first tubular member and a second tubular memberupwardly extending outside are right-left symmetrically arranged in the upper end wall of the kinetic energy chamber in an intercommunication manner, the upper end surface of the first tubular memberis provided with a first gate valve in an intercommunication manner, a second gate valve is disposed on the upper end surface of the second gate valve in an intercommunication manner, a third tubularmember is disposed on the upper end surface of the first gate valve in an intercommunication manner, and a fourth tubular member is disposed on the upper end surface of the second gate valve in an intercommunication manner. The kitchen garbage disposer has a simple structure and is convenient to use, and the kitchen garbage disposer adopts low temperature steam to drive a cam structure to shattergarbage, and effectively improves work efficiency.

Owner:朱晓凤

A steel structure building staircase with switchable feeding surface

ActiveCN110017002BEasy to operateStable structureTreadsTread-and-riser unitsControl theoryMechanical engineering

The invention discloses a steel structure building stair capable of switching feeding surfaces. The stair comprises a plurality of steel structure stair units, the plurality of steel structure stair units are sequentially arranged in a height reduction manner from left to right; and based on each steel structure stair unit, a fixed shaft, a horizontal stair plate and a vertical stair plate are included, the fixed shaft is symmetrically sleeved by two horizontal sleeve blocks, the horizontal sleeve block is rotationally connected with the fixed shaft, and the upper end of the right side of thehorizontal sleeve block is fixedly connected with the horizontal stair plate, two vertical sleeve blocks are arranged between the two horizontal sleeve blocks on the fixed shaft in a sleeved mode androtationally connected with the fixed shaft, and the vertical stair plate is fixedly connected to the left sides of the upper ends of the vertical sleeve blocks. According to the invention, only a damaged structure needs to be simply replaced, and the building stair can continue to be used and is very simple; therefore, one-time operation does not need to be carried out on the whole structure whenswitching is carried out each time, and the step type or inclined plane type switching is more labor-saving and more convenient.

Owner:江苏华木空间结构有限公司

Sewage deep treatment device

InactiveCN108499482AEasy to installEasy maintenanceShaking/oscillating/vibrating mixersTransportation and packagingMedicineSewage

The invention discloses a sewage deep treatment device. The sewage deep treatment device comprises a base body, wherein the base body is internally provided with an energy feeding cavity; a first conduction cavity is arranged below the energy feeding cavity and is located in the base body; a second conduction cavity located in the base body is formed in the left side of the first conduction cavity; a third conduction cavity located in the base body is formed in the left side of the second conduction cavity; a piston part is communicated with the inner part of a lower end wall of the third conduction cavity; a first hollow pipe and a second hollow pipe, which upward stretch out of the outer part, are communicated with the inner part of an upper end wall of the energy feeding cavity in a bilateral symmetry manner; a first opening / closing valve is communicated with the upper end face of the first hollow pipe and a second opening / closing valve is communicated with the upper end face of thesecond hollow pipe; the upper end face of the first opening / closing valve is communicated with a third hollow pipe; a fourth hollow pipe is communicated with the upper end face of the second opening / closing valve. The device disclosed by the invention is simple in structure and convenient to use; a low-temperature steam driving cam structure is used for stirring sewage and the working efficiencyis effectively improved.

Owner:刘永达

Novel activated carbon processing device

InactiveCN108479567AEasy to installEasy maintenanceShaking/oscillating/vibrating mixersTransportation and packagingActivated carbonEngineering

The invention discloses a novel activated carbon processing device. The novel activated carbon processing device comprises a base body, the base body is internally provided with a power output cavity,a first transmission cavity positioned in the base body is installed below the power output cavity, the left side of the first transmission cavity is provided with a second transmission cavity positioned in the base body, the left side of the second transmission cavity is provided with a third transmission cavity positioned in the base body, the lower end wall of the third transmission cavity isinternally communicated and provided with a cylinder, the upper end wall of the power output cavity is internally communicated and leftwards and rightwards symmetrically provided with a first hollow pipe and a second hollow pipe which are upwards extended to the exterior, the upper end face of the first hollow pipe is communicated and provided with a first electric control valve, the upper end face of the second hollow pipe is communicated and provided with a second electric control valve, the upper end face of the first electric control valve is communicated and provided with a third hollow pipe, the upper end face of the second electric control valve is communicated and provided with a fourth hollow pipe. The device is simple in structure, and convenient to use. The device uses a low-temperature steam driving cam structure to stir activated carbon, so the working efficiency is effectively improved.

Owner:乐康

Efficient aluminum alloy profile heat treatment device

InactiveCN112813366AAchieving transfer performanceTake the hassle out of turningLifting framesPhysicsCrank

The invention discloses an efficient aluminum alloy profile heat treatment device which comprises a transverse sliding rail, a longitudinal sliding rail and working boxes. The longitudinal sliding rail is arranged at one end of the transverse sliding rail, and the two working boxes are arranged on one side of the transverse sliding rail side by side. By rotating a crank, an adjusting rod rotates; threaded strips are arranged at the connecting positions of the adjusting rod and two nut seats, the two threaded strips are connected with the nut seats through threads, and the threaded connection directions are opposite, so that the two nut seats are far away from each other, then two second rotating plates rotate and are matched with two first rotating plates, the lifting work of a supporting plate is achieved, and a sealing plate is attached to a stop piece; an aluminum alloy profile is fed into a heating layer, a box door is closed, a closed space is formed, heat treatment work is conducted, the heat treatment efficiency is high, a rotating rod is rotated, the rotating rod rotates along a rotating shaft, the rotating rod is inserted into a clamping groove in a clamping block, a rotating disc is rotated, the position of the clamping block is fixed, disassembly is convenient, and discharging is easy and fast.

Owner:广州修好车工程服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com